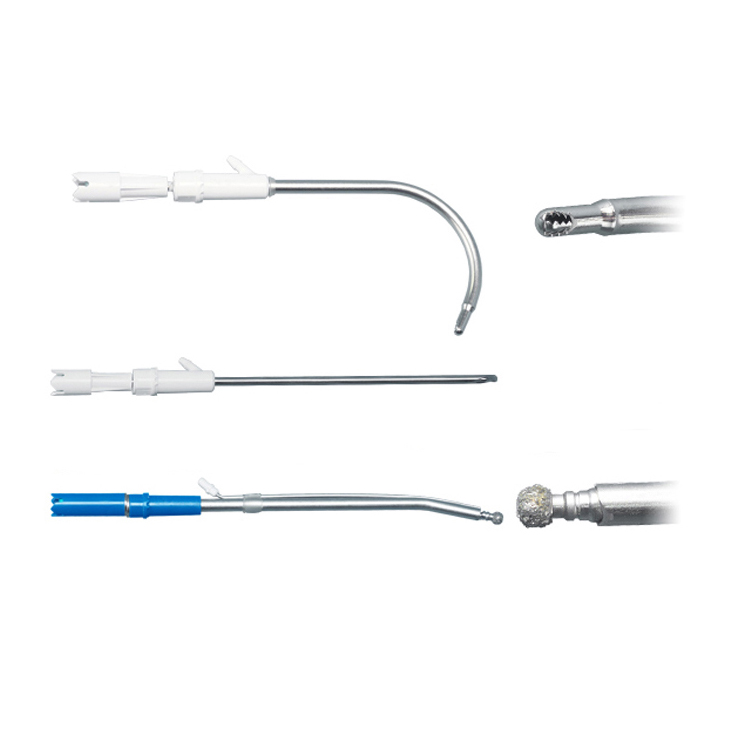

内窥镜零部件

内窥镜零部件

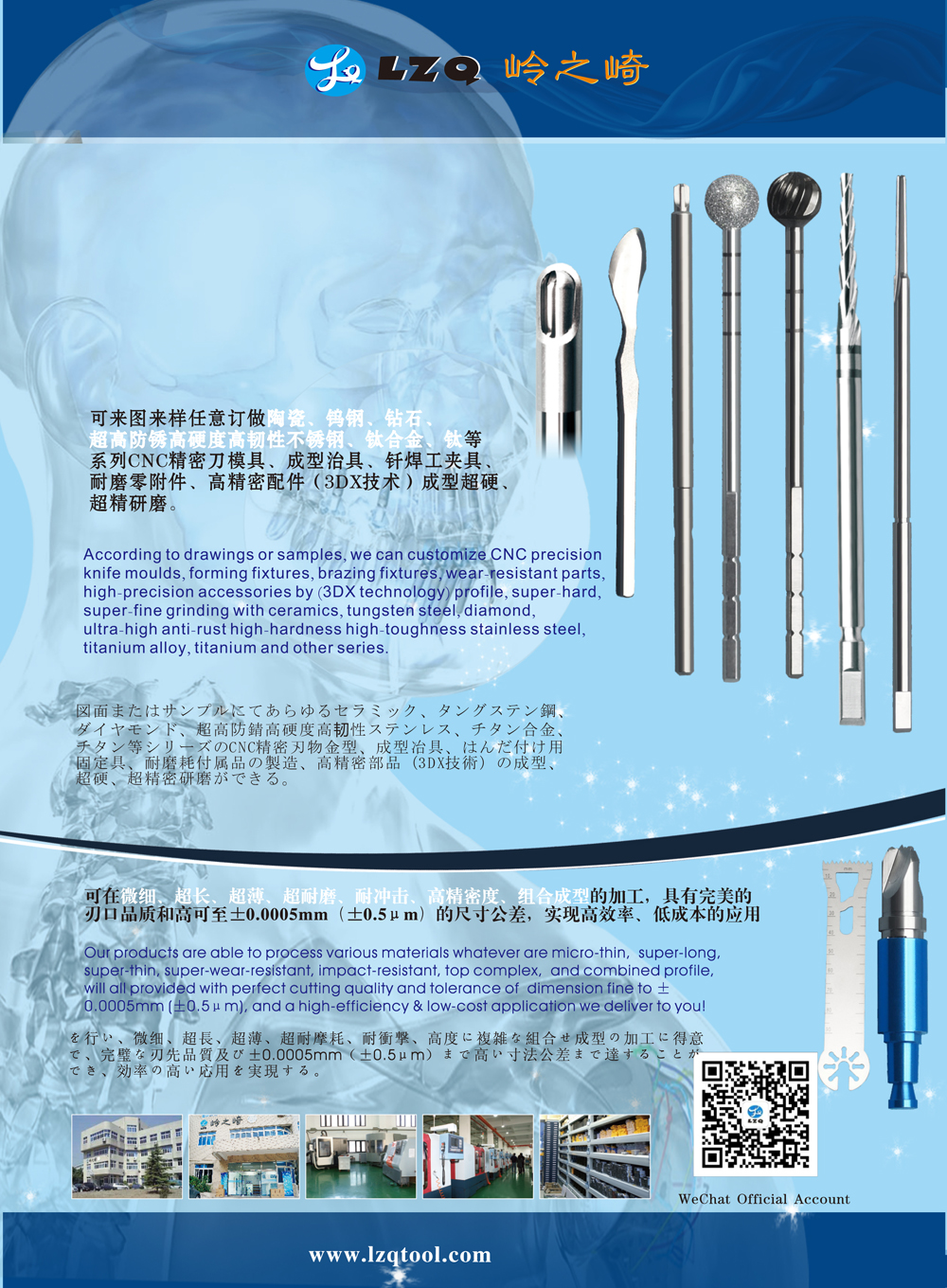

特性

应用领域: 用于关节镜内窥镜

材 料: 超防锈高硬度不锈钢,钨钢,陶瓷,一般不锈钢

产品描述

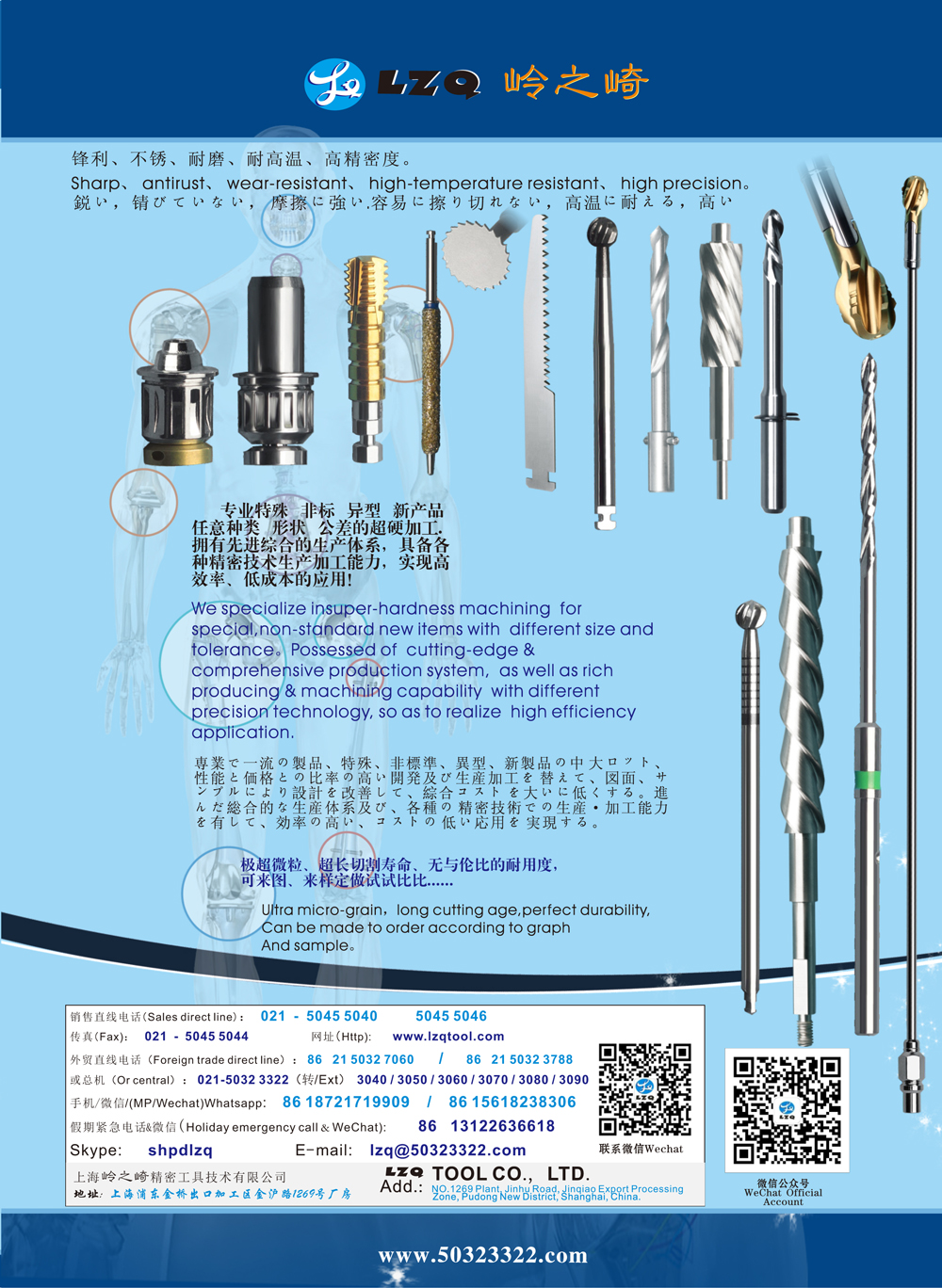

LZQ是一家生产各种刨刀的OEM代工工厂,例如,内窥镜/关节镜刨刀 P259, 骨科钻针 P227, 取骨器 P165, 钻头096,等等。我们也可以为客户生产成套手术工具。

我们使用不锈钢和陶瓷材料。

我们可以根据客户提供的任意图纸或者样品来生产任何刨刀,而且性价比很高。

超锋利刃口&超高防锈(AA)&超高耐磨&超高精密度内外配合)

可依要求生产不同刃部材料类型(陶瓷类、钨钢类、高品级不锈钢类、钛及钛合金类、一般不锈钢......等系列)

超高防锈&超高耐磨不锈钢&超锋利刃口&超高精密度内外配合(ASTM440PH/ASTMF899)

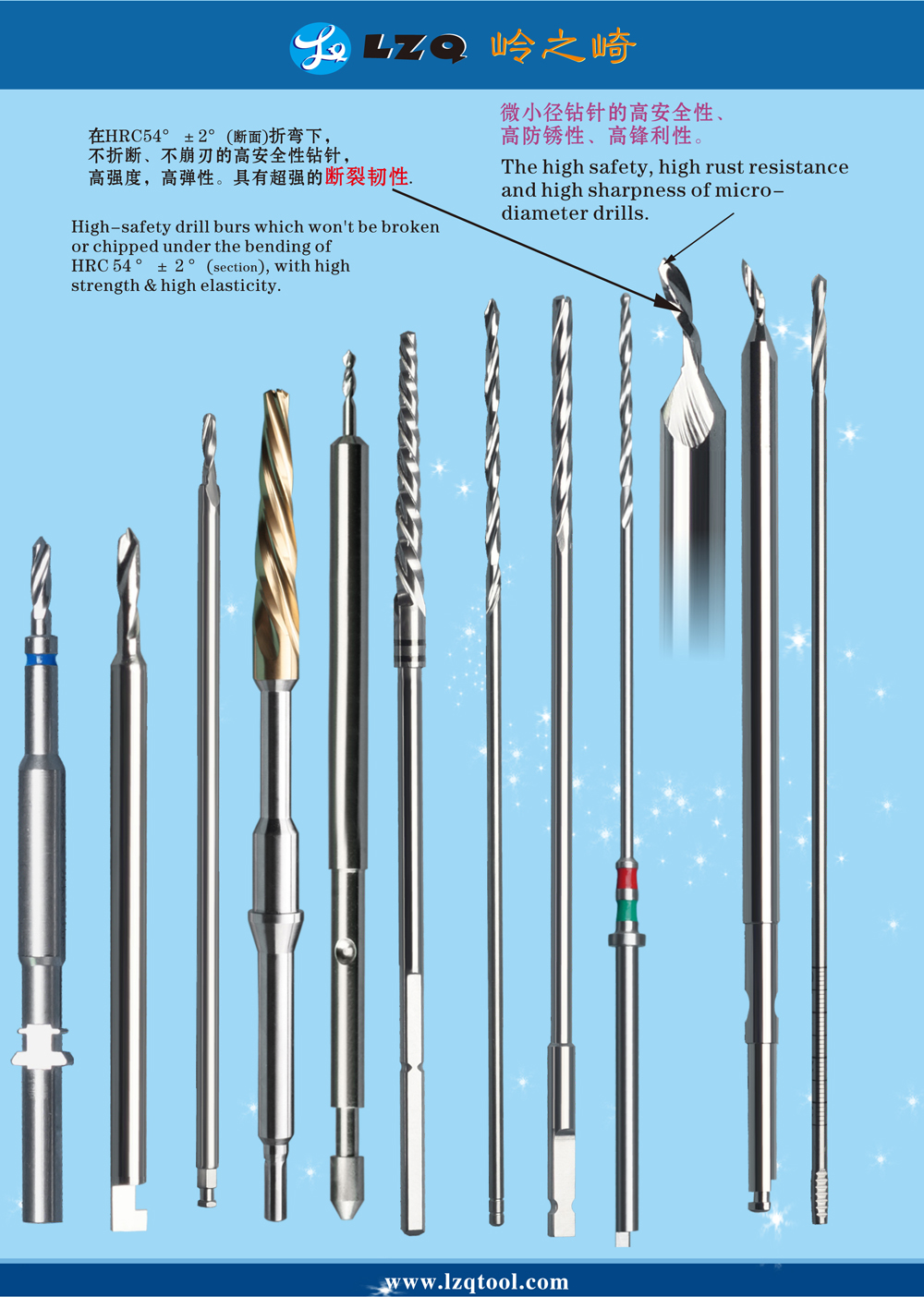

刃部材料:

1. 超高防锈高耐磨高抗冲击高韧性不锈钢(AA)(HRC54°±2°断面)(常规常备)

2. 常规标准防锈超高耐磨不锈钢(A)(HRC64±°2°断面)

3. 对焊硬质合金(钨钢)类(HRA87°~94°)系列(可定制)

采用六轴联动CNC磨削中心,可依要求研磨任意形状,锋利要求,容屑槽深浅要求,刃数,齿型,螺纹角度……

超高防锈高耐磨高抗冲击高韧性不锈钢(AA)(HRC54°±2°断面),内外刃口锋利性保持时间超长,(耐磨耗性能)使用寿命是传统的AISI304L不锈钢产品的60~100倍以上,并可使刃口长时间保持超锋利状态。

内外刀均为六轴五联动CNC超硬砂轮(CBNC)高速研磨,刃口可近于镜面光洁度,刃口超锋利(后角可在20°~70°系列),手术中切割超干净,优良.

内外刀均为CNC高精密磨床反复精研磨加工,所以头部的内外配合间隙为0.010~0.015mm之间的精密型,手术中切割无毛刺、毛边、毛点残留,属高端精密型

批量时,有必要可协助开模具及批量完成注塑部分,或批量完成机加工柄部的部分.

endoscopic parts

Characteristics

- Application domain: for arthroscopy endoscope

Material: Super-high rust-resistant high-hardness stainless steel, tungsten steel, ceramics, general stainless steel

Products Description

LZQ is an OEM factory for all kinds of shaver blades, such as Endoscopic/Arthroscopic Shaver blade P259, Bone Drill Point P227, Bone Fetcher P165, Drill Bit 096, ect.

We use the material of stainless steel and ceramic.

We are capable to produce any shaver blades according to drawings or samples provided by customer with a favorable cost-performance.

(Ultra-sharp cutting edge & ultra-high anti-rust (AA) & ultra-high wear-resistant & ultra-high precision cooperation of inner tubes and outer tubes)

As customers require, we can produce blades with different materials (ceramics, tungsten steel, high grade stainless steel, titanium and titanium alloys, general stainless steel ... series)

Ultra-high anti-rust & ultra-high wear-resistant stainless steel & ultra-sharp edge & ultra-high precision internal and external matching(ASTM440PH/ASTMF899)

Cutting edge Material Types:

1. ultra-high anti-rust high wear-resistant stainless

steel(AA)(HRC54°±2°Section)(regular stock)

2. general anti-rust ultra-high wear-resistant stainless

steel(A)(HRC64±°2°Section)

- butt welding hard alloy(carbide)(HRA87°~94°)series(customizable)

6-axis CNC grinding center can be used to grind any shape, sharpness requirement, depth requirement of chip flutes, number of flutes, tooth profile, thread angle...

Ultra-high rust-proof, high wear-resistant, high-impact & high-toughness stainless steel (AA) (HRC54°±2°section), The inner blade and outer blade sharpness retention time is super-long. And lifetime (wear resistance) is 60~100 times higher than that of the traditional AISI304L product,which can make the cutting edge stay super sharp for a long time.

The inner blade and outer blade are grinded with high speed by 6-axis 5-linkage CNC superhard grinding wheel (CBNC). The edge can be close to the mirror finish, super-sharp (relief angle can be 20 ° ~ 70 ° series), super clean and excellent cutting during surgery.

The inner blade and outer blade are finish-grinded repeatedly by CNC high precision grinding machine, so the head internal and external cooperation clearance is between 0.010~0.015mm, which is the precision type. The cutting is free of burrs and wool residue. It is a high-end precision type.

In batch order, if necessary, we can help customers open mould and finish the injection molding part or finish the machining shank part in batches