牙科种植体起子

牙科种植体起子

特性

牙科手术有特殊情况,因此不能使用简单的起子。

不再感觉鼻窦和敏感区域失控。

您的植入物将被双重锁定,手动控制。

应用领域: 用于牙科种植

材料:手术不锈钢

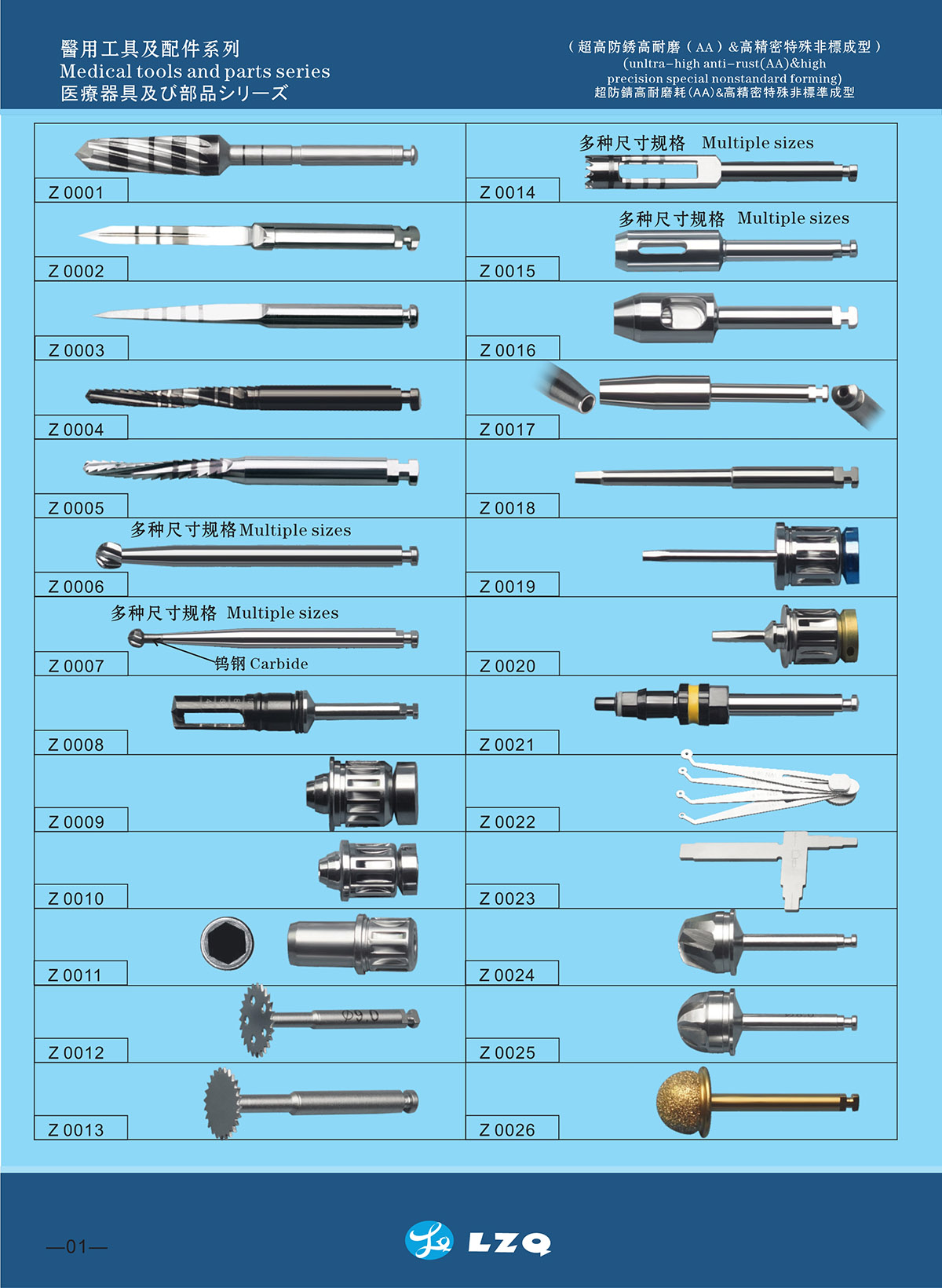

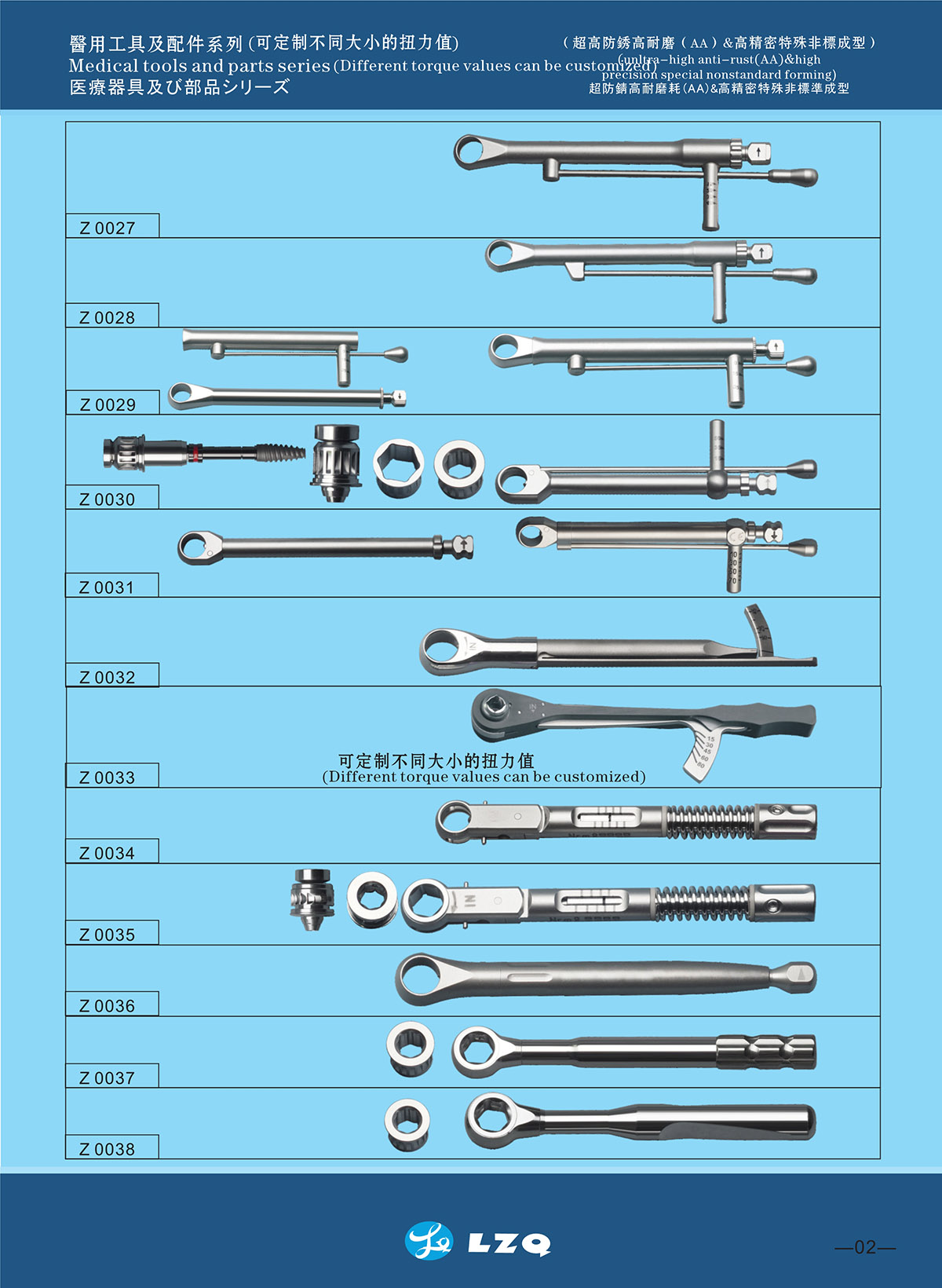

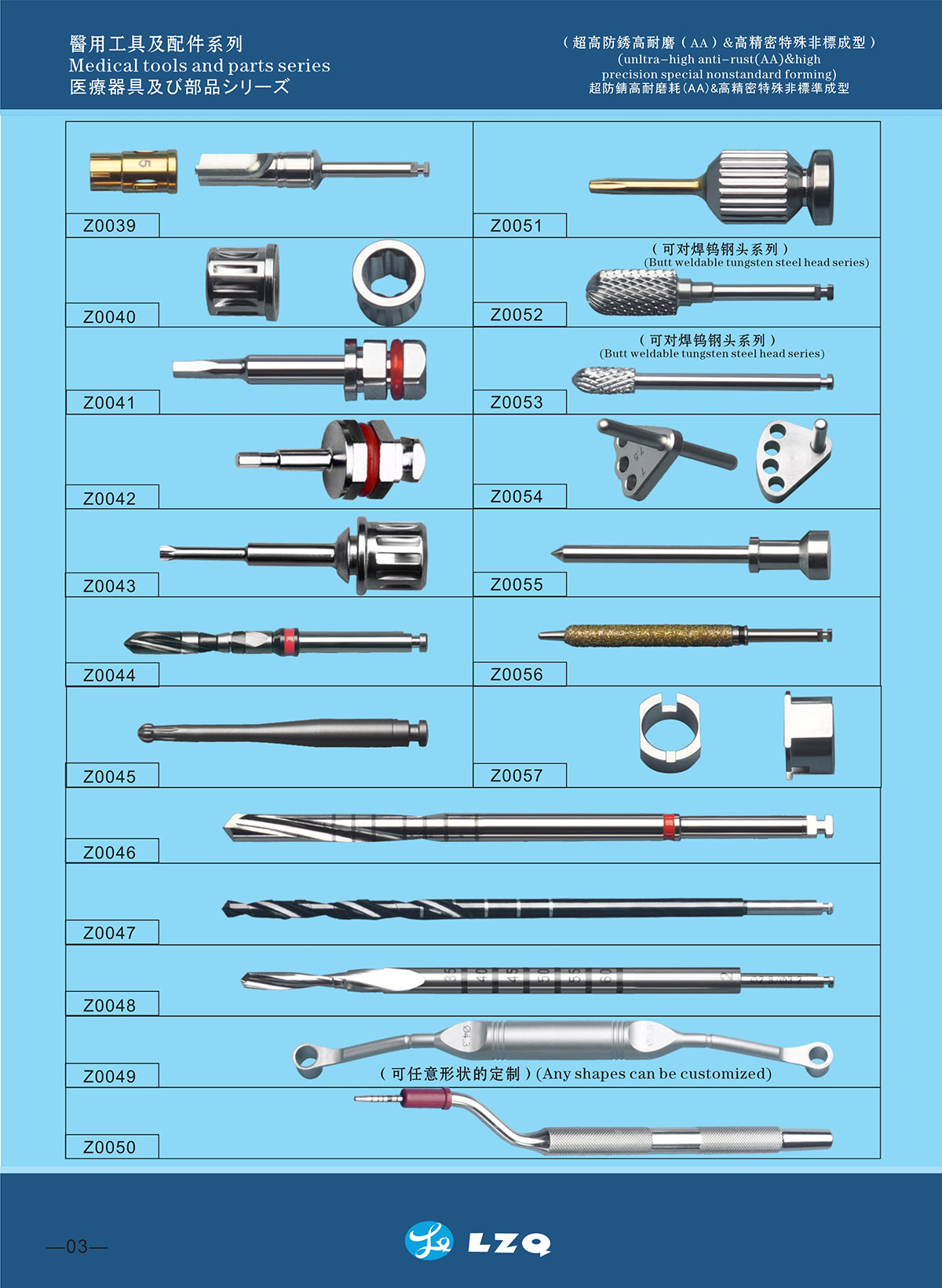

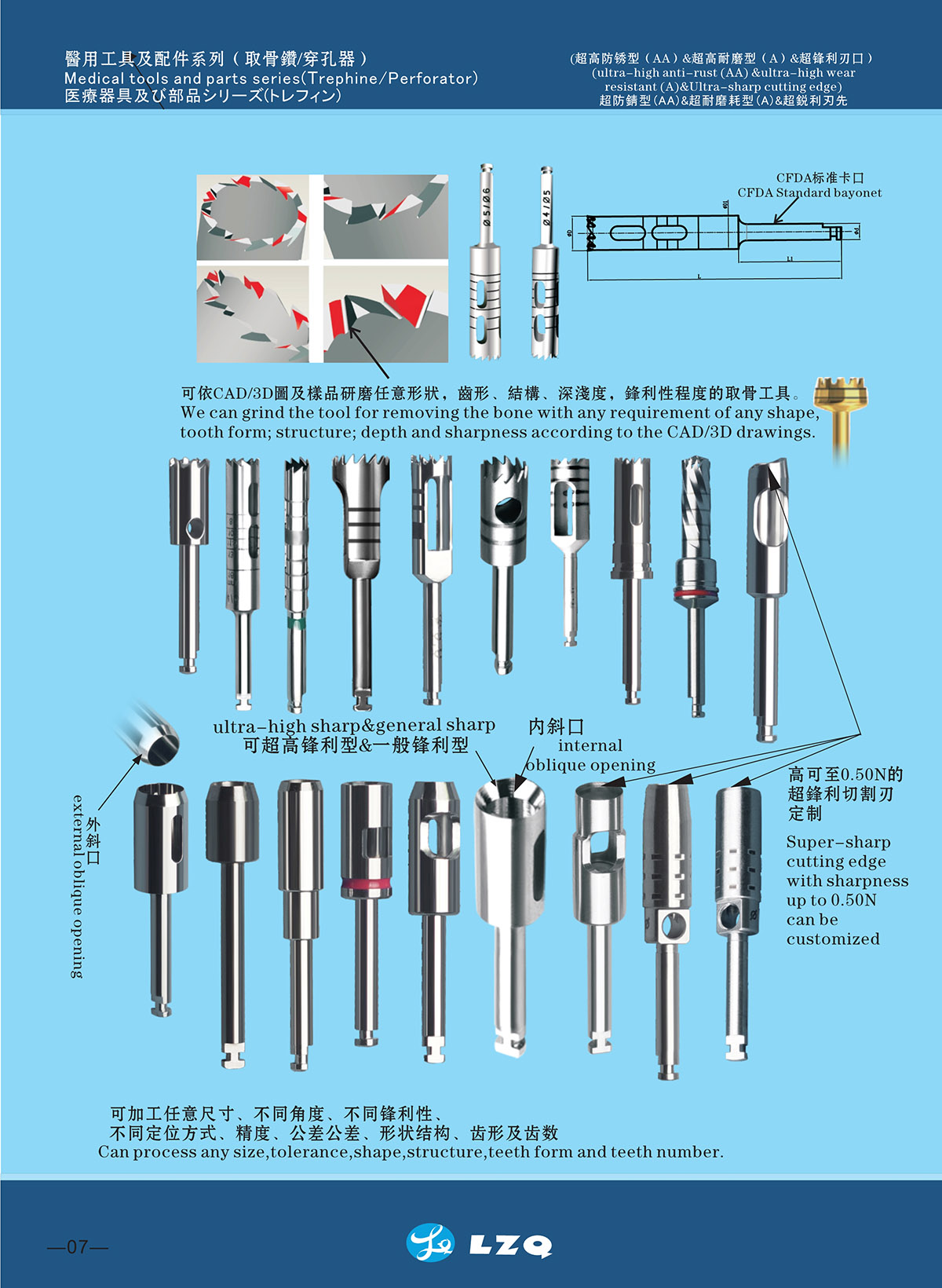

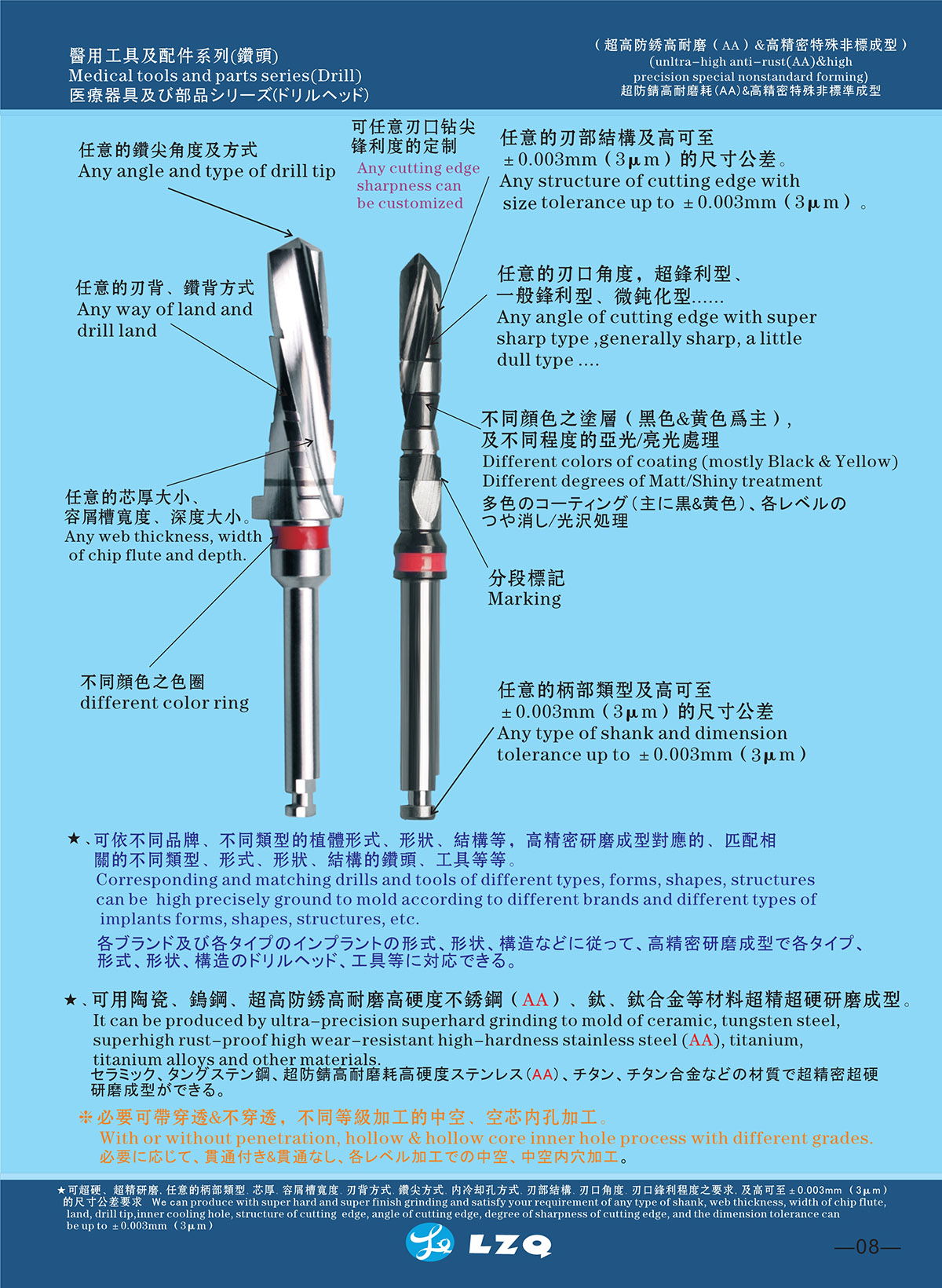

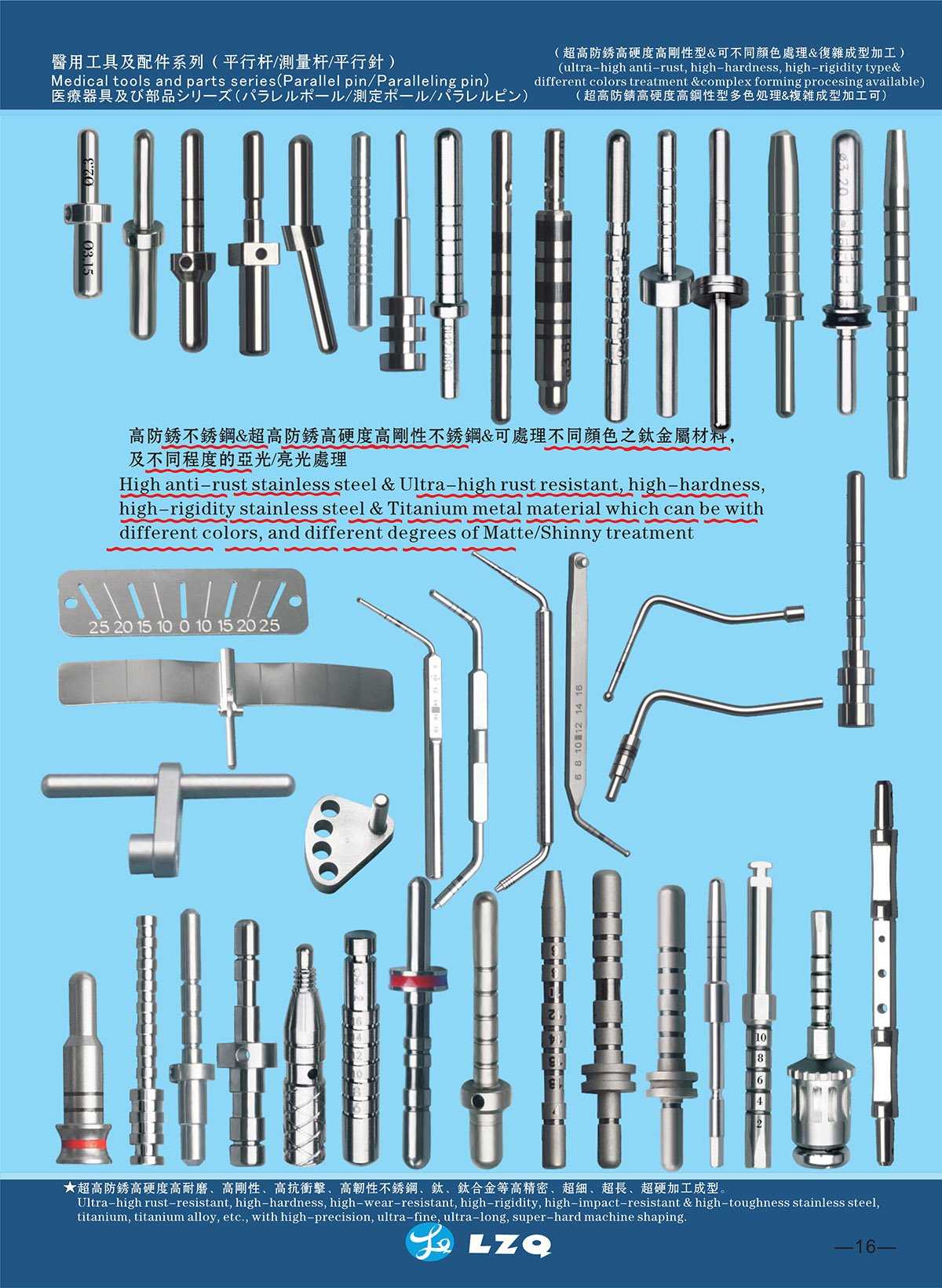

专业特殊、非标、异型、新产品、任意种类、形状、公差的超硬加工。

※ 如有类似,可FAX地址,来电索取图片中的样品及相关样本资料供参考(只限小金额)※

常年備存原材料、半成品、成品 3000萬 ~ 4000萬RMB周转的在庫品,依圖依樣現生產,具有極強的性價比……欢迎实地指导。

产品描述

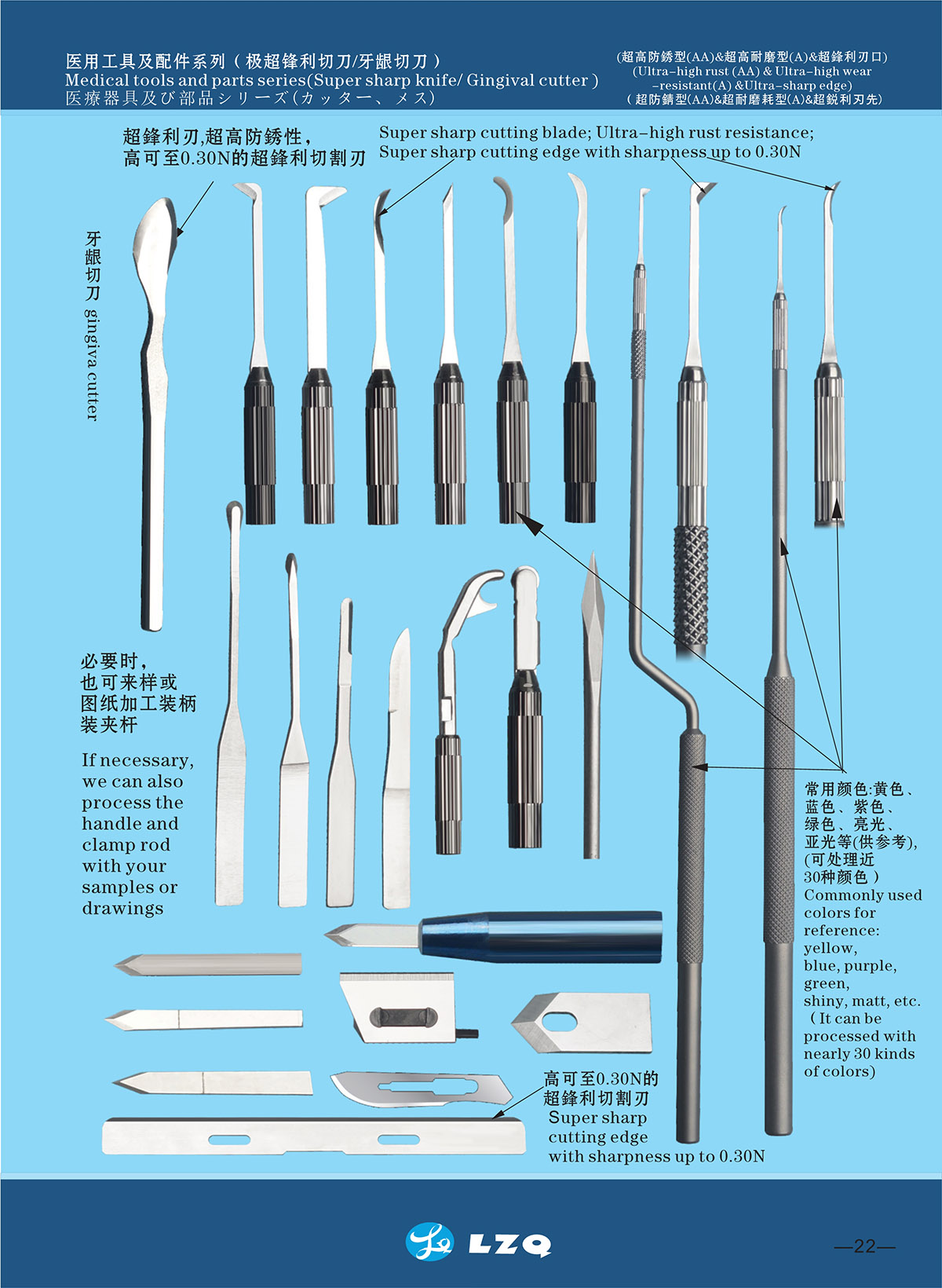

(超高防锈型(AA)&常规标准防锈型(A)&可超高精密加工)

可定制任意形状的梅花起子,公差高可至±0.002mm(依螺钉实样实配)

可不同材料等级及加工等级的生产

可配制不同颜色及不同材料的圆圈帽

可不同材料及不同颜色,也可定制不同颜色的高耐磨PEEK,PPSU扁成型(非纯圆圈类)的高端卡圈。

刃部材料类型:

1.超高防锈高耐磨不锈钢类(AA)(HRC54°±2°断面).(常规常备)

2.常规标准防锈高耐磨不锈钢类(A)(HRC45°~64°断面)系列.

3.钛及钛合金类(HRC35°~42°)系列.

4.陶瓷类(HRA85°~94°)系列,(HRC67°~84°)系列。

5.钨钢类(HRA81°~94°)系列,(HRC60°~84°)系列。

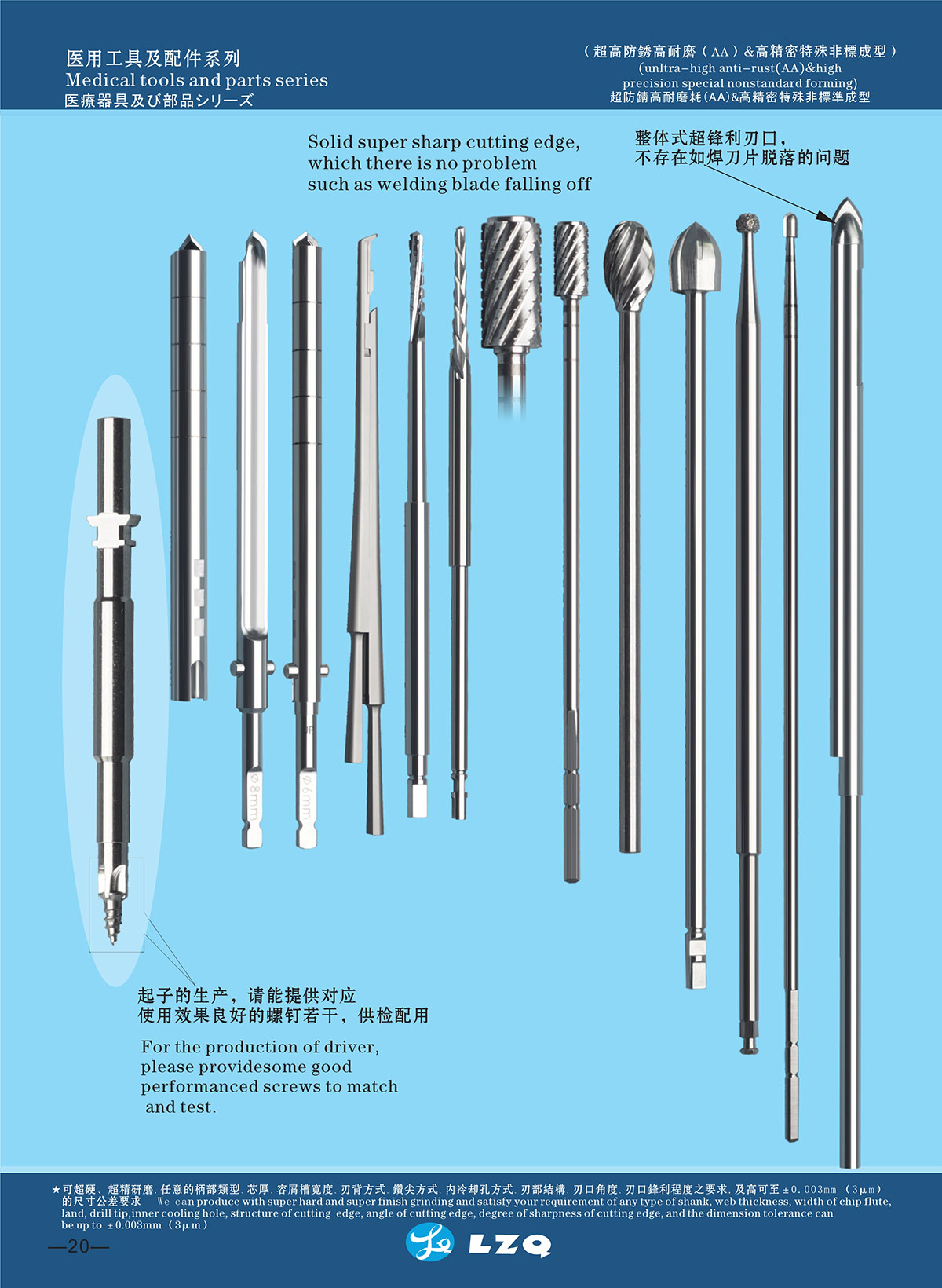

★、可以生产不同的头部形式、形状、精研磨成型。

★、不同形状之卡口(部分只供参考,实际可依样依图形状,尺寸公差生产)

★、可以生产不同的柄部形式、形状、精研磨成型。

起子的生产,请能提供对应使用效果良好的螺钉若干,供检配用。

★、要求带橡胶圈的请能提供对应的螺钉及配件,以便依实际检测匹配的功能来确定,生产研磨尺寸公差,当然橡胶圈用户自己提供更好。

材料:

①超高防锈高耐磨不锈钢系列(AA)(HRC54°±2°断面)(常规常备)

②常规标准防锈高耐磨不锈钢系列(A)(HRC45°~64°断面)

③有必要在超高精研磨下,起子处精度可至±0.002mm(±2um)

UNS S42000

(超高防锈不锈钢A+) (淬硬处理HRC60°±2°断面)

高防锈、高锋利度、超高耐磨不锈钢,具有超高的耐磨耗(超高硬度)性能及高标准的防锈、耐腐蚀性能,相应一般不锈钢具有2~3倍的使用寿命,切削刃切割锋利性保持时间超长。无标示下5%中性盐雾实验( ASTM B117)符合FDA高标准时间约300小时后无生锈现象,如重复使用、手术后建议能及时清洁烘干处理。

应用范围广,耐磨性、锋利性表现优异,可生产极为复杂、高精密的柄部形状及成型的超锋利刃部结构。

Dental Implant Driver

Characteristics

Dental surgeries have special cases, so simple drivers cannot be used.

Stop feeling out of control in the sinuses and sensitive areas.

Dental Implant Driver:

Your implant will be double locked, and you can control it manually.

Application domain: for dental implantology

Material: surgical stainless steel

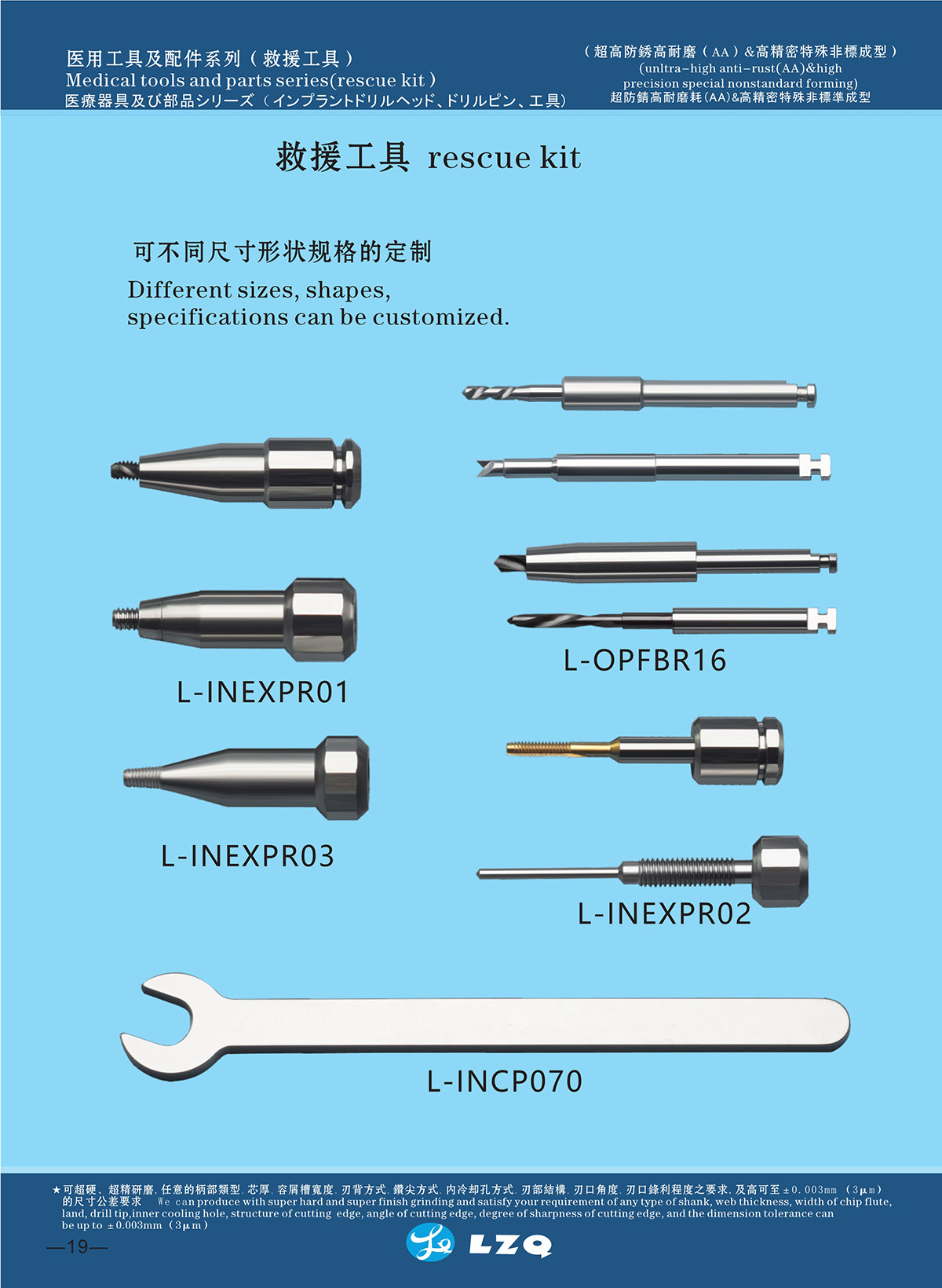

Products Description

LZQ is an OEM factory for all kinds of dental implant screwdrivers, such as hand driver, machine driver, handpiece driver, abutment drive, internal hex drivers, external hex drivers, slot driver, star driver, Torx driver, square driver, Octa abutment driver, ratchet implant driver, torque driver, tap driver contra-angle driver, short driver, medium driver, long driver and stainless steel driver, ect. We can produce a whole kit of tools for customers’ surgical cases.

We use the material of stainless steel.

We are capable to produce any size and shape of dental implant drivers according to drawings or samples provided by customer with a favorable cost-performance.

Type: hand or machine

Connection: ratchet, torque wrench, solid abutment, handpiece, closure screws, fixture and healing caps (extra short, short, medium, long, extra long); different shapes and sizes of head are also available, such as internal hex, external hex, star, Torx, Octa, square, ect. Compatible with most dental implant products globally available now

Different functions of different types:

1. Torque driver connection, to adjust the retention force.

2. ratchet wrench connection, for extension of simple mount length, and use in case of inputting hand-torque.

3. Fixture connection, to place or remove a fixture after the separation of the mount.

4. Handpiece connection, for screwing the implants into place.

5. Tip holding function: stopper designed for the prevention of fracture of the holding part and occurrence of foreign matter such as blood stain during surgery

6. Removing broken screws, this tool should be used together with the guide for each system. When the marked part of the reverse drill is exposed above the guide, connected to the fixture, make use of the screw-holder to remove the broken Screws

7. Connector used for connecting the driver for square torque to the round torque wrench.

To manually tighten fixing screws, to close abutment. To tighten all kind of implants. Safeguard maximum torque to avoid possible fracture. Some with diverging hex for better screw tightening and transport; Handling cover screws for Implants and Healing Cap.

Grooves, laser mark and color ring: designed for checking during the connection, can be customized according to your specific requirement.

Coating: can also be done if you need.

Heavy duty with robust design and proven material, complete solution for critical problems which might occur in the prosthetics process

Material:

①Super-high anti-rust high wear resistance stainless steel

series(AA)(HRC54°±2°Section)(regularly stock)

②General anti-rust high wear resistance stainless steel series(A)(HRC45°~64°Section)

③If necessary, with super-high finish grinding, the driver finish could reach ±0.002mm.

UNS S42000

(Super-high rust-proof stainless steel A+) (hardened HRC60°±2°Section)

Ultra-high anti-rust, high-sharpness and super-high wear-resistant stainless steel, with super-high wear resistance (super high hardness) performance and high standards of rust and corrosion resistance. It has a service life of 2 ~ 3 times longer than that of general stainless steel. The cutting edge keeps for a super-long time of cutting sharpness. Unmarked, with 5% Neutral salt spray test (ASTM B117), it doesn't rust after 300 hours, which meet FDA high standard. If for repeated use, it is recommended to clean and dry it in time after every surgery.

Wide range of applications. With excellent abrasion resistance and sharpness, it can be used to produce extremely complex, high-precision handle shapes and formed super-sharp edge structures.