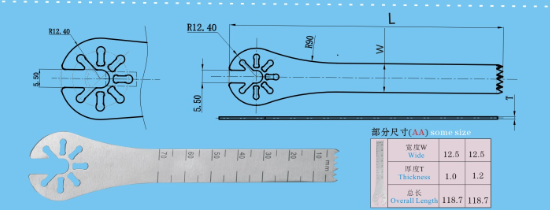

医用往复式锯片,往复式骨刀片,医用往复式刀片

医用往复式锯片,往复式骨刀片,医用往复式刀片

特性

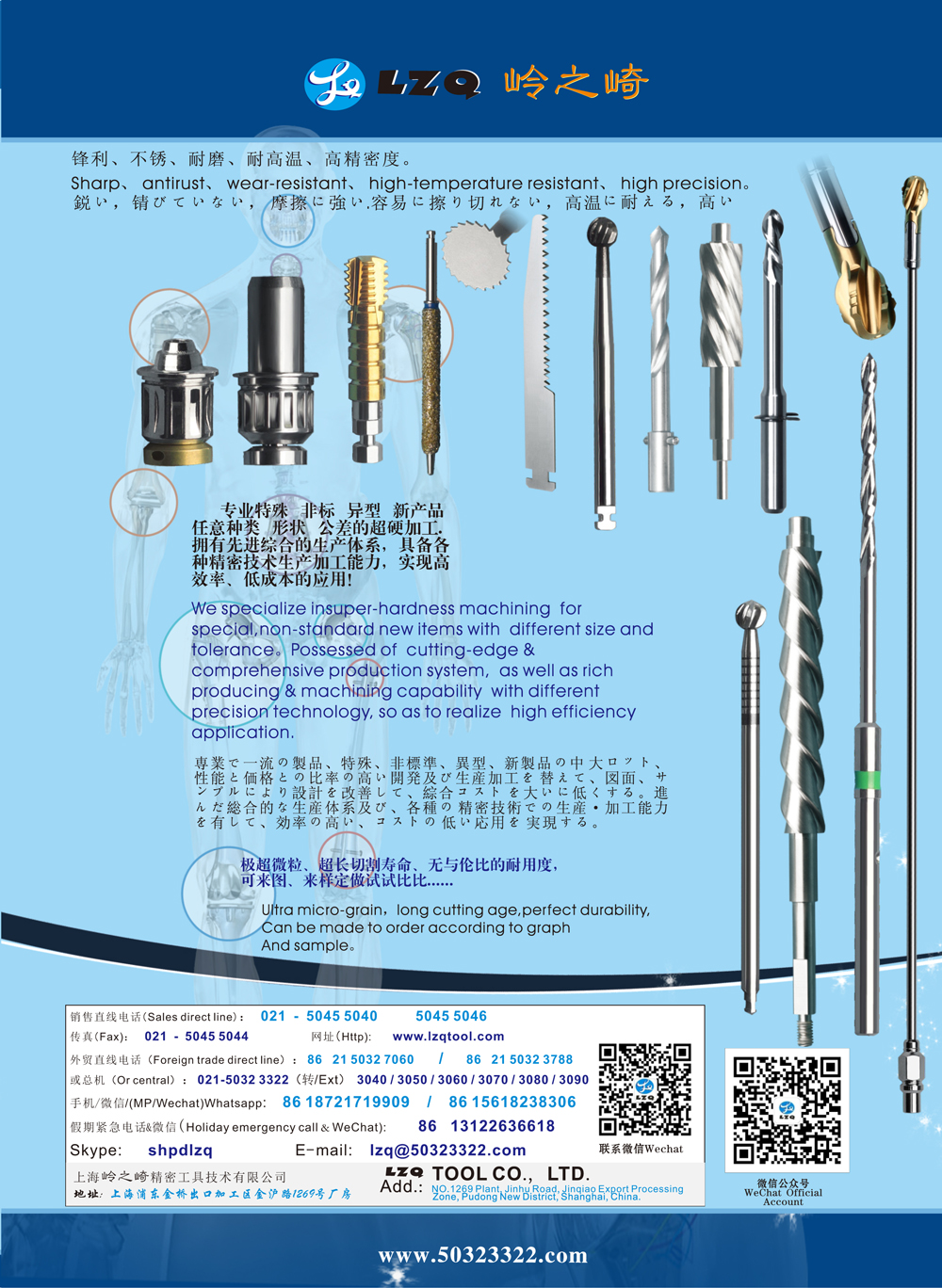

应用领域: 骨科

材 料: 超高防锈高硬度不锈钢, 普通防锈超高耐磨不锈钢,陶瓷

类型

骨锯,牙龈锯

产品描述:

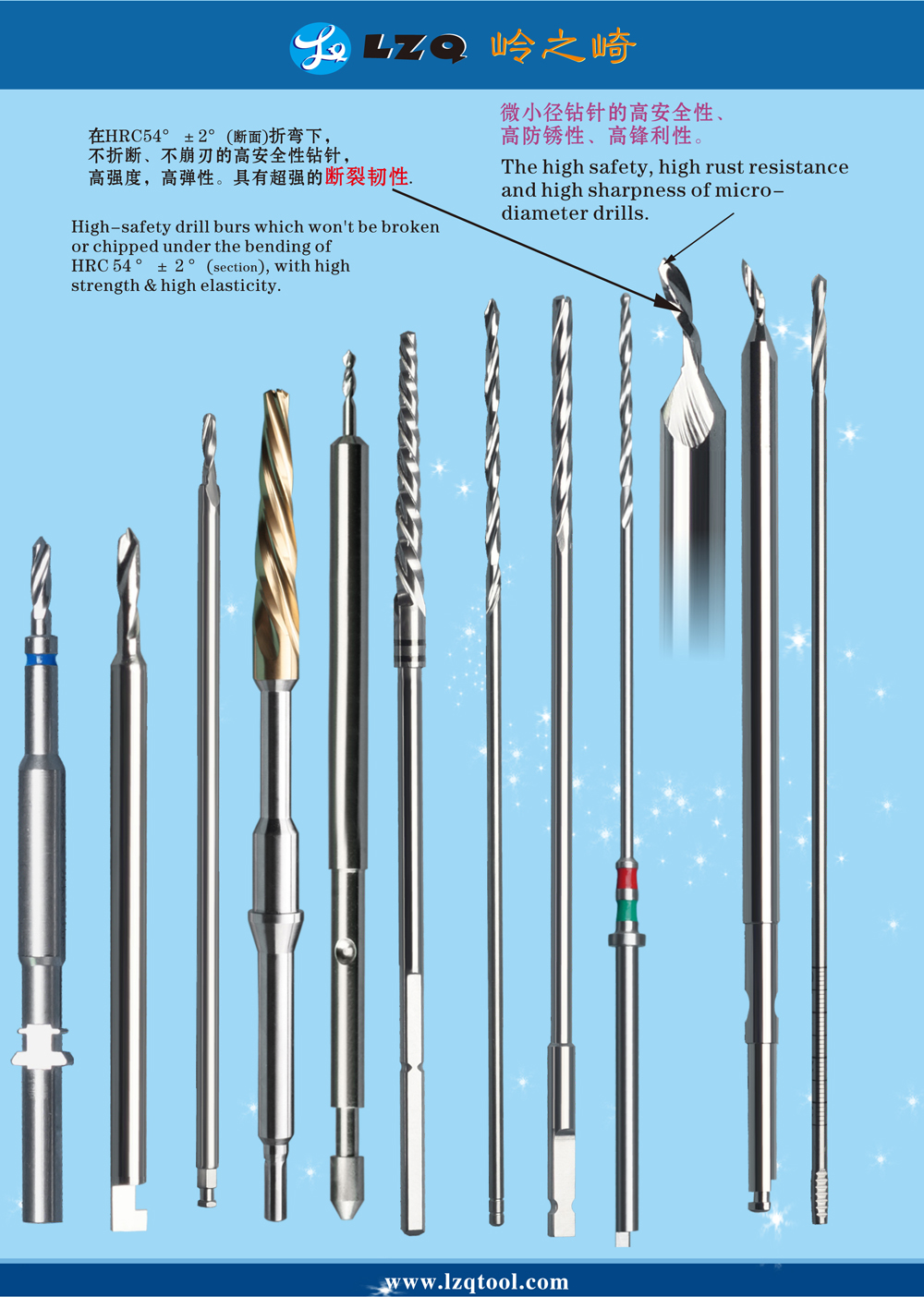

LZQ是一家生产各种牙科种植扳手的OEM代工工厂,例如,骨锯 P250,切割锉/骨锉 P190, 钻套P31, 钻头096, 基台/转移杆P25, ,等等。我们也可以为客户生产成套手术工具。

我们使用超高防锈高硬度不锈钢材料。

我们可以根据客户提供的任意图纸或者样品来生产任何牙科种植扳手,而且性价比很高。

材料分类:

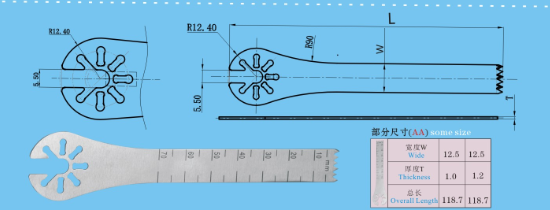

1.超高防锈高耐磨不锈钢类(AA)(HRC54°±2°断面)(常规常备)

2.常规标准防锈耐磨不锈钢类(A)(HRC52°±2°)系列

3.普通防锈超高耐磨不锈钢(A)(HRC62°±2°)

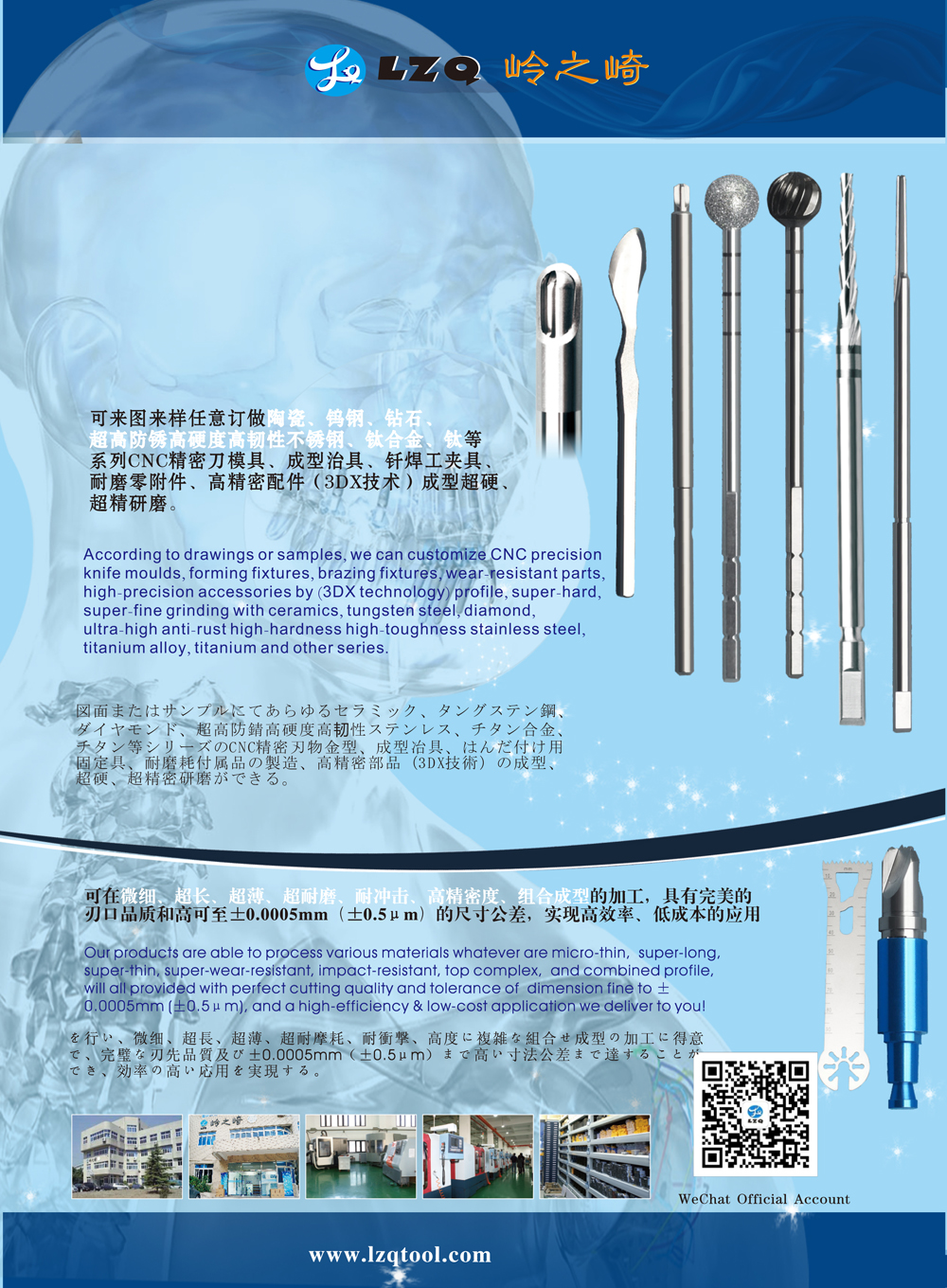

可来图、来样任意订做陶瓷、钨钢,不锈钢、钛合金、钛钻石等系列,高精密组合成型治具、钎焊工夹具、耐磨零附件、高精密配件(3DX技术)成型超硬、超精研磨

询盘请能提供使用效果最好的样品及参考页脚注明每种产品的详细要求、材料种类、尺寸公差、工件成品和半成品图纸、所用的设备、设备价值RMB(以判断其刚性及跳动等)、每月消耗的数量、原用产品类型及其不足之处?被加工材料及其硬度HRC?……

如有不足之处,请一定不吝指教:是易钝化?易崩刃?还是……?并能提供使用效果最佳——新的和旧的实样。

Characteristics

Application domain: orthopedics

Material: Ultra-high anti-rust high-hardness stainless steel,

general rust-proof ultra-high wear-resistant stainless steel,

ceramic

Type

Bone saws, Gums saws

Products Description

LZQ is an OEM factory for all kinds of dental implant wrenches, such as, Bone Saw P250,Cutting Bur/Bone File P190, Drill Stopper P31, Drill Bit 096, Abutment/Transfer P25, , etc. We can also produce a whole kit of tools for customers’ surgical cases.

We use the material of Ultra high anti-rust and high-hardness stainless steel

We are capable to produce any wrenches according to drawings or samples provided by customer with a favorable cost-performance.

Material classification:

1. Ultra-high rust-proof & wear-resistant stainless steel (AA)

(HRC54°±2°Section) (regular stock)

2. Conventional standard rust-proof and wear-resistant stainless

steel (A)(HRC52°±2°) series

- Ordinary antirust stainless steel (A) (HRC62°±2°)

We can customize high-precision-combination molding fixture, brazing fixture, wear-resistant accessories, high-precision parts by (3DX technology) molding superhard and superfine grinding, with ceramic, tungsten steel, stainless steel, titanium alloy, titanium diamond series, according to customers' drawings or samples,

When you make inquiry, referencing to the page footer, please provide samples with best work performance, and specify the detailed requirements, material types, dimensional tolerances, drawings of finished and semi-finished products, equipment used or equipment value (to judge its rigidity and runout, etc), monthly consumed qty, type of original samples and its inadequacies, the workpiece material to be processed by sample and its hardness HRC? ...

Any deficiencies, please do not hesitate to let us know: Is it easy to get passivated? Or tipping? Or something else? Please provide new and old samples--with the best working performance--for us to check and test.