上颌窦植入术丝锥,锥形种植体外科丝锥

上颌窦植入术丝锥, 锥形种植体外科丝锥

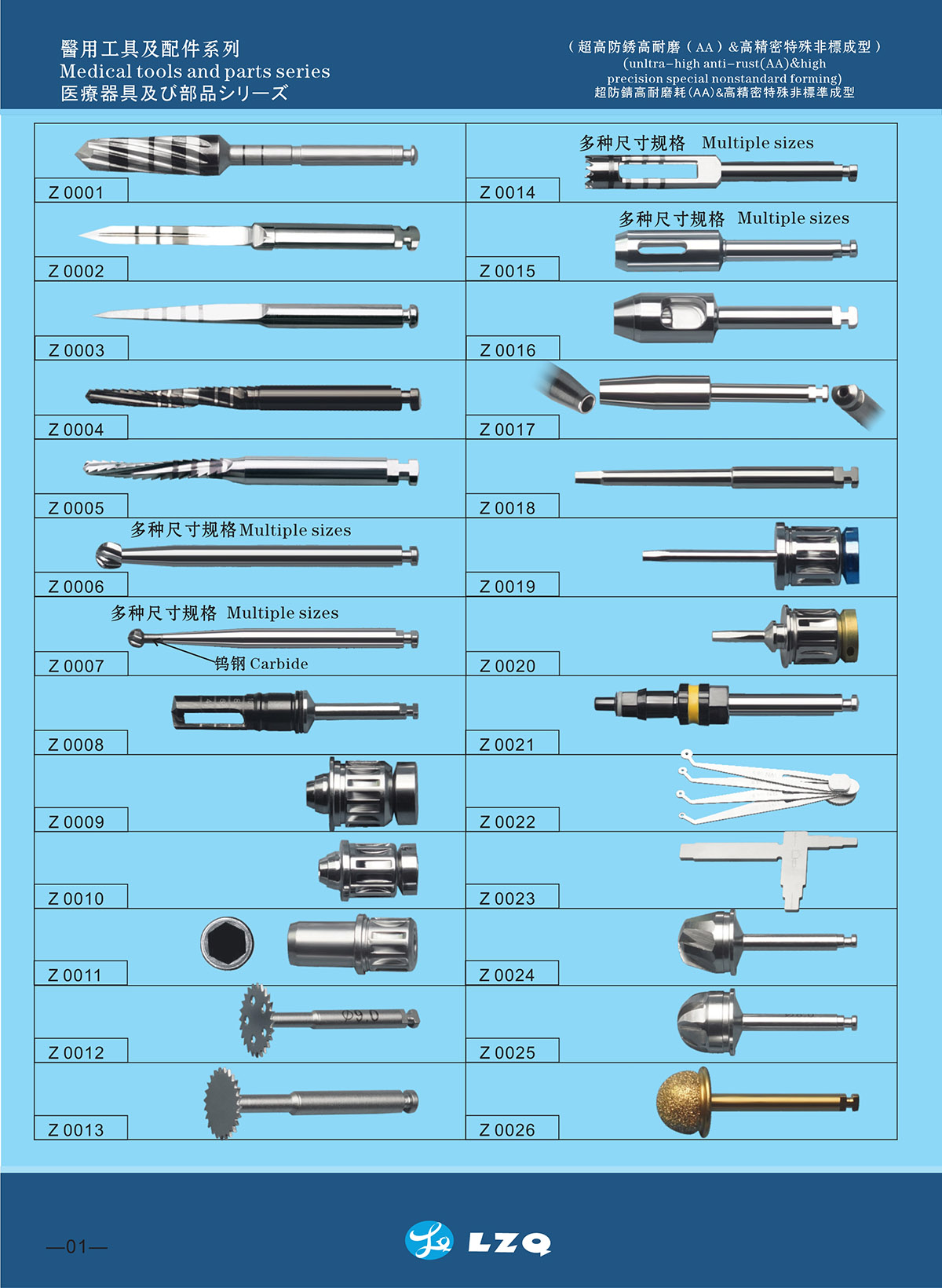

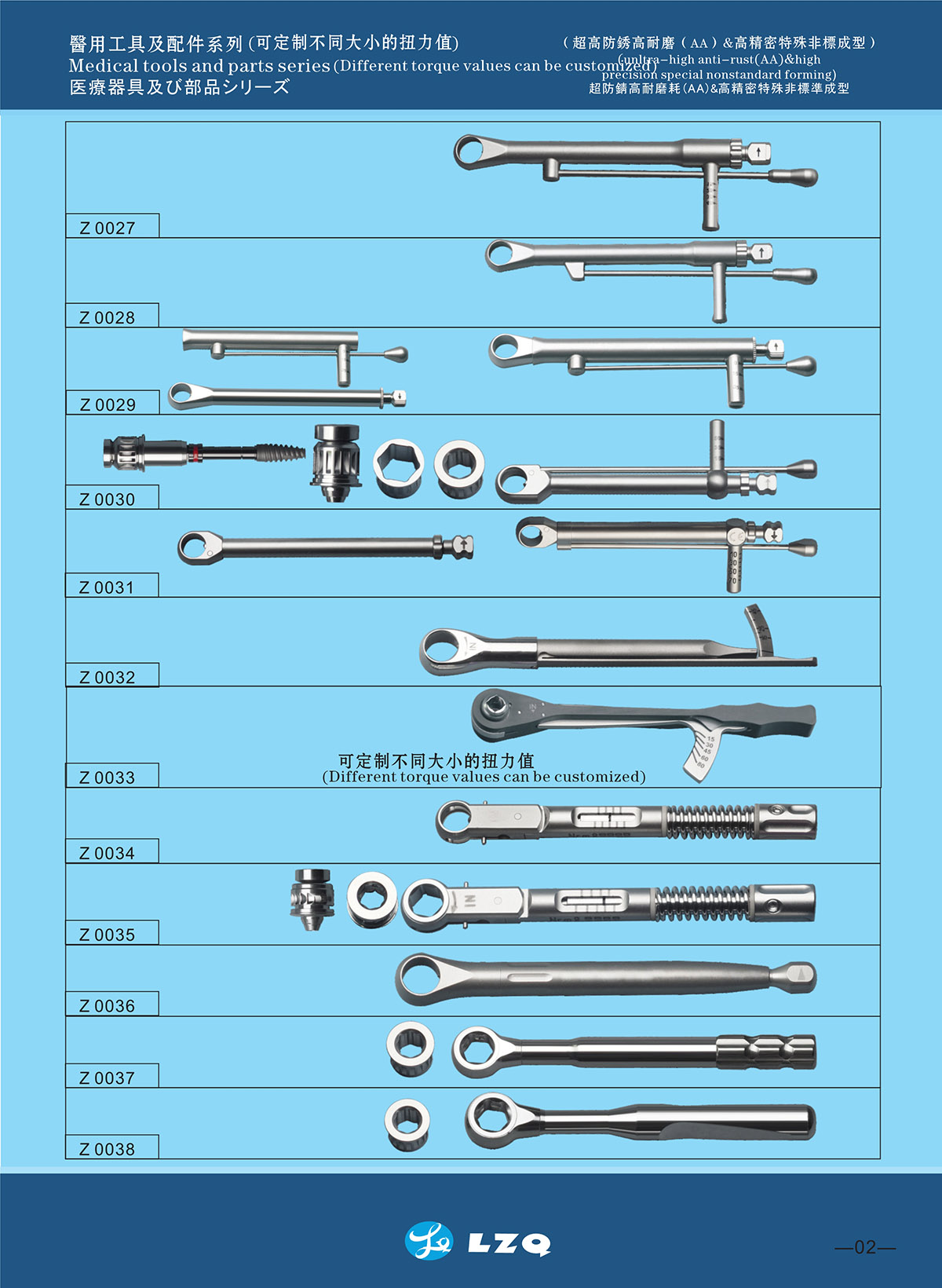

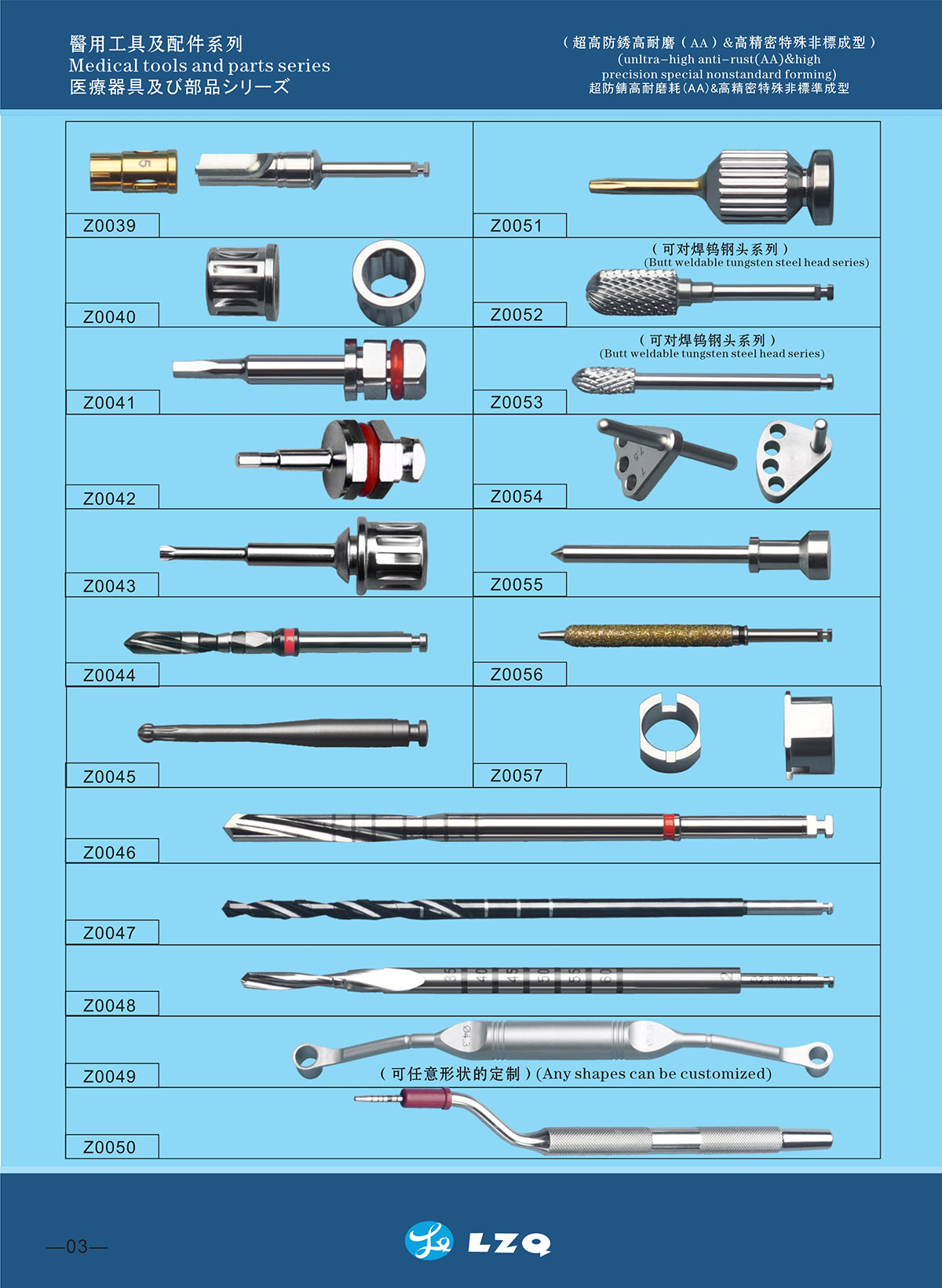

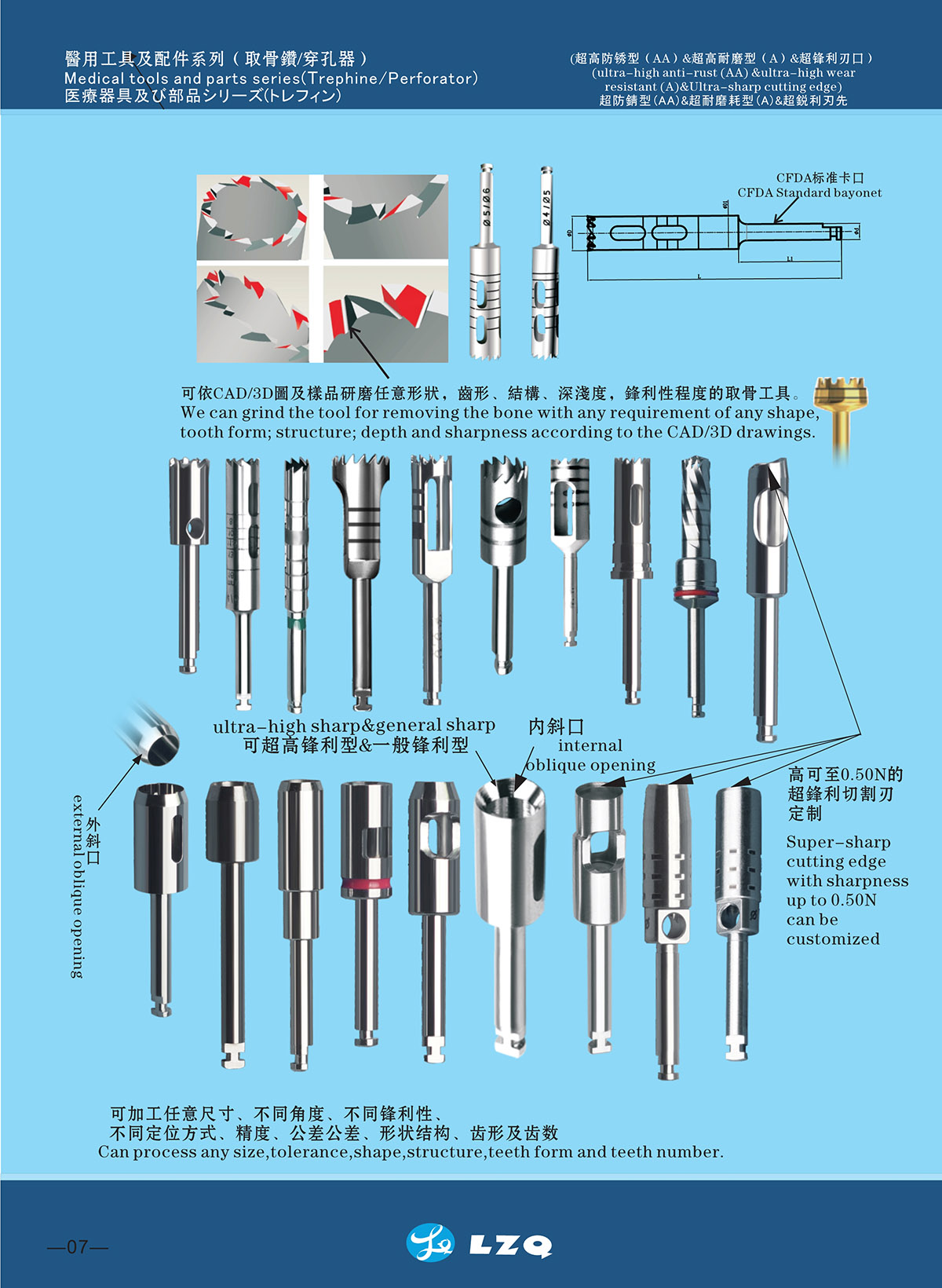

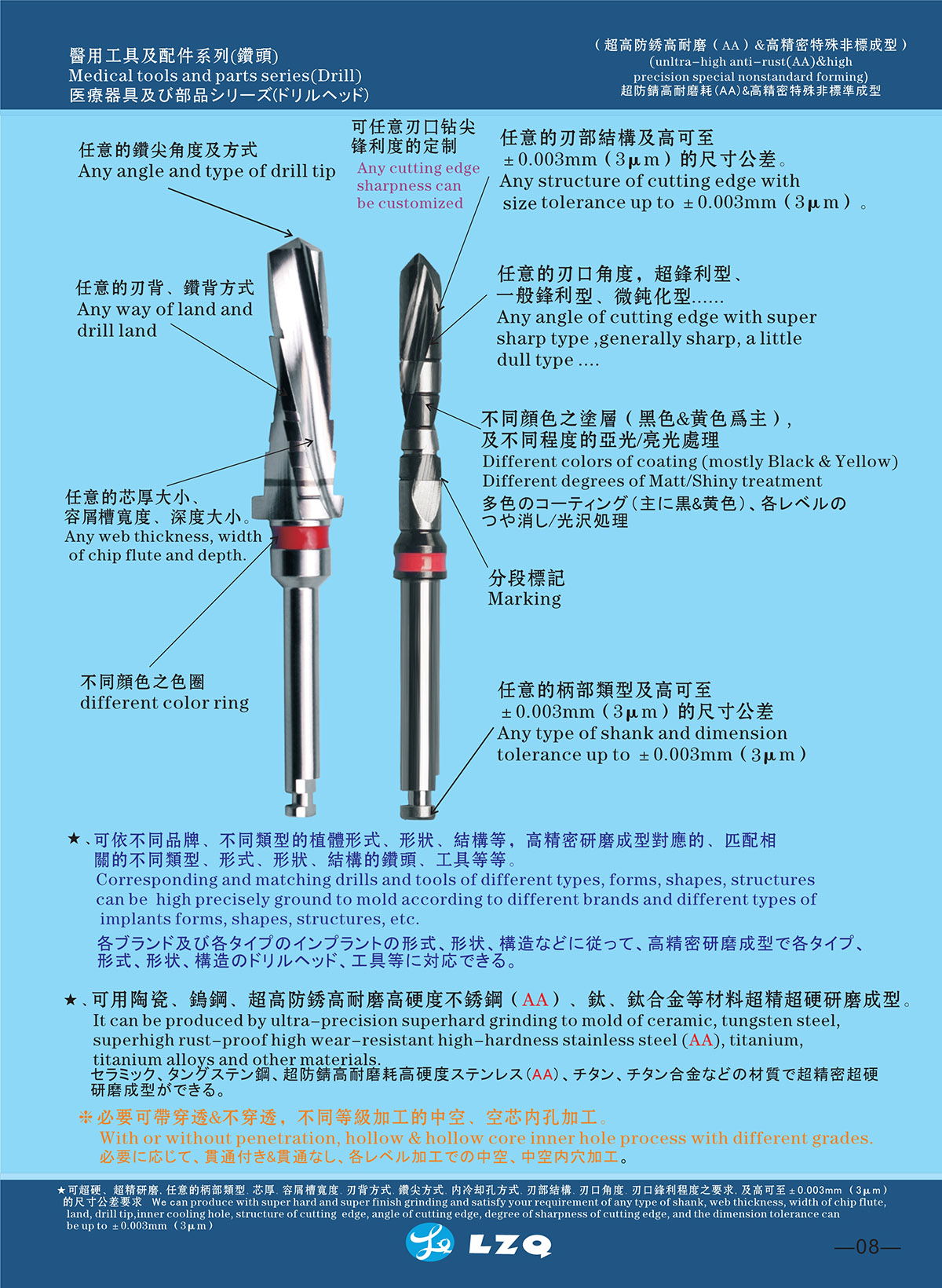

特性

应用领域: 用于种植

材 料: 超防锈高硬度不锈钢,钨钢,陶瓷,一般不锈钢

产品描述

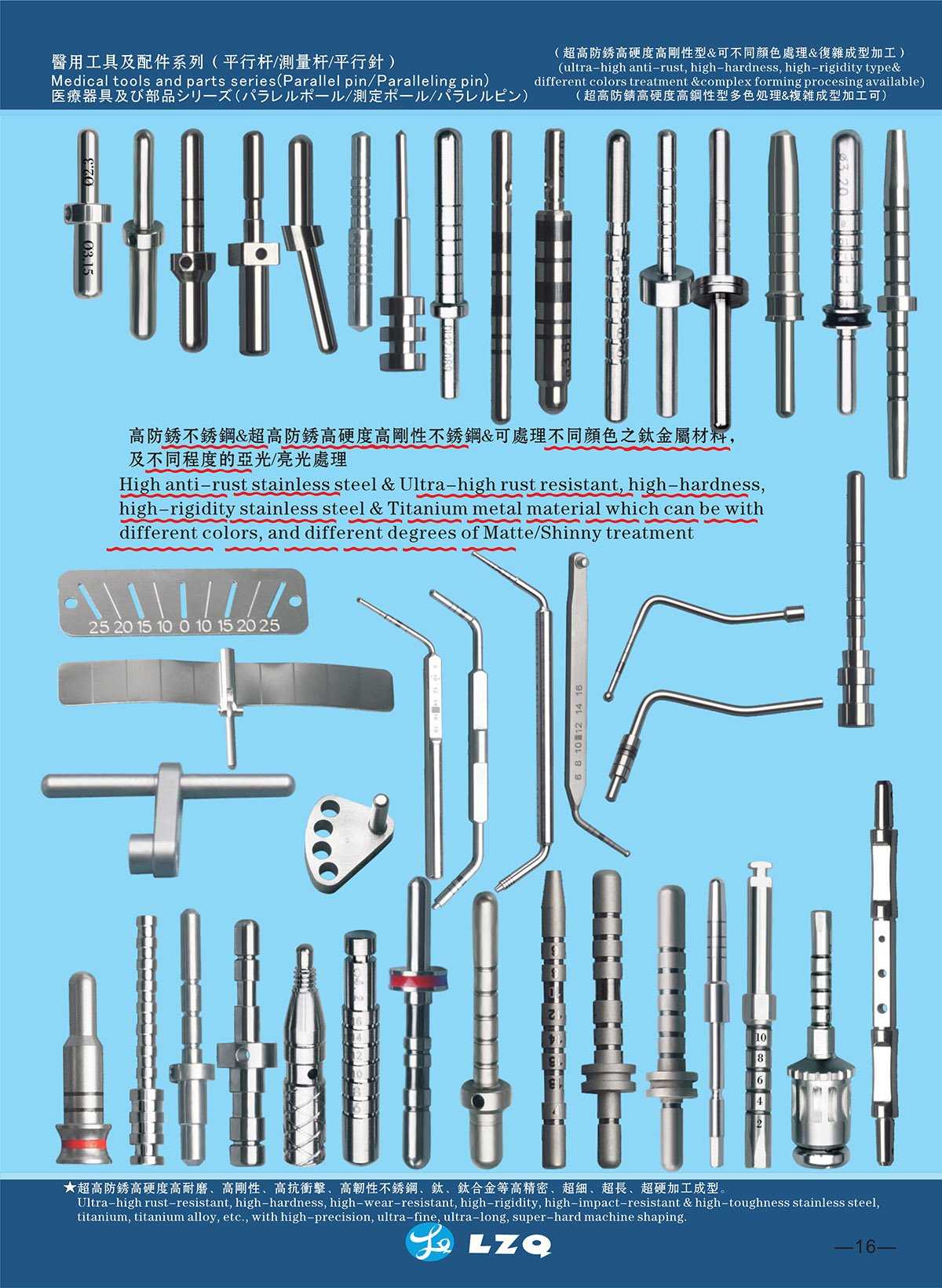

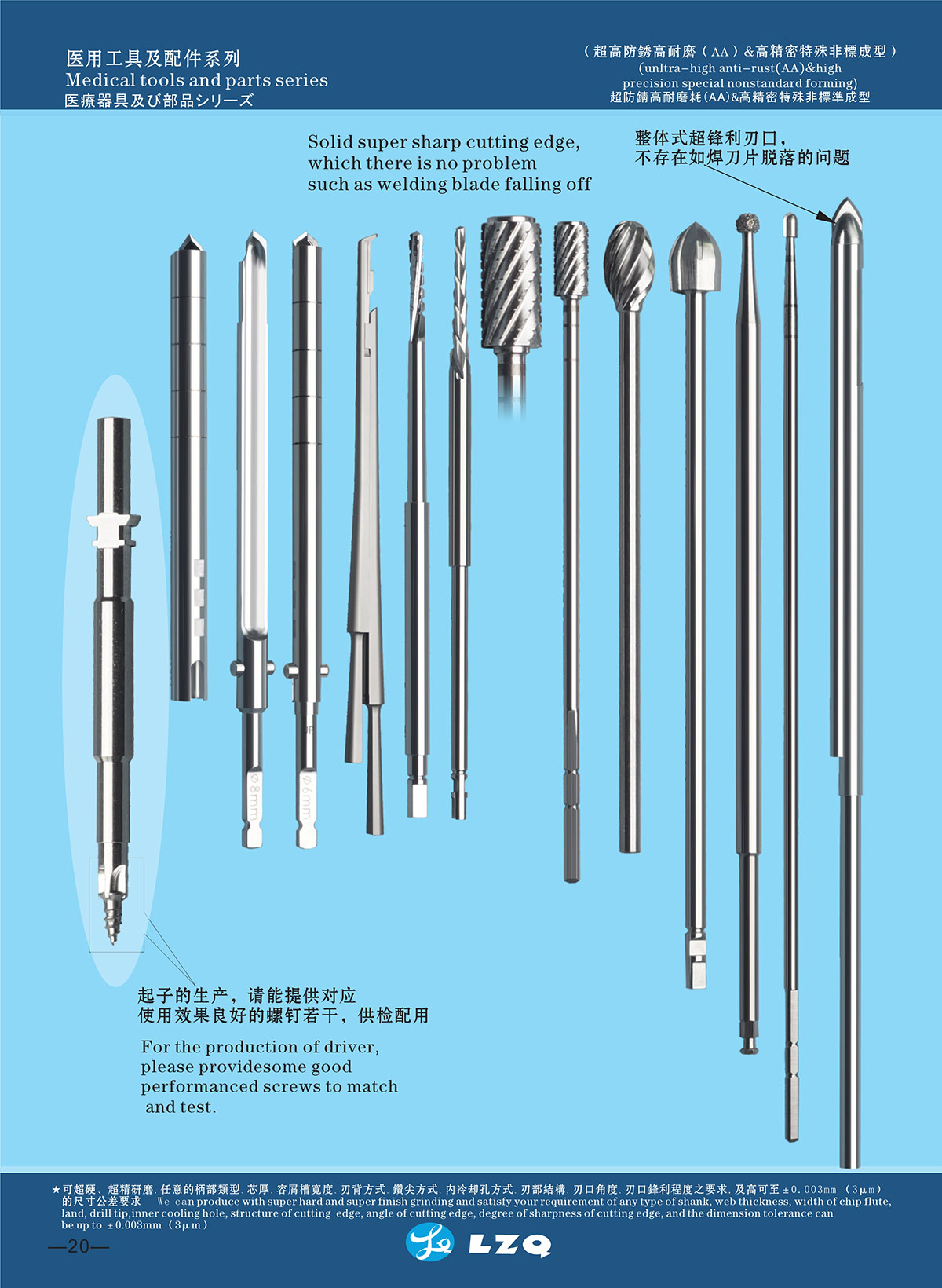

LZQ是一家生产各种牙科种植工具的OEM代工工厂,例如,基台/转移杆P25,平行针P37, 扳手P53, 螺丝起子P79, 丝锥/丝攻P152, 取骨器 P165, 先锋钻 P172等等。我们也可以为客户生产成套手术工具。

我们使用不锈钢材料。

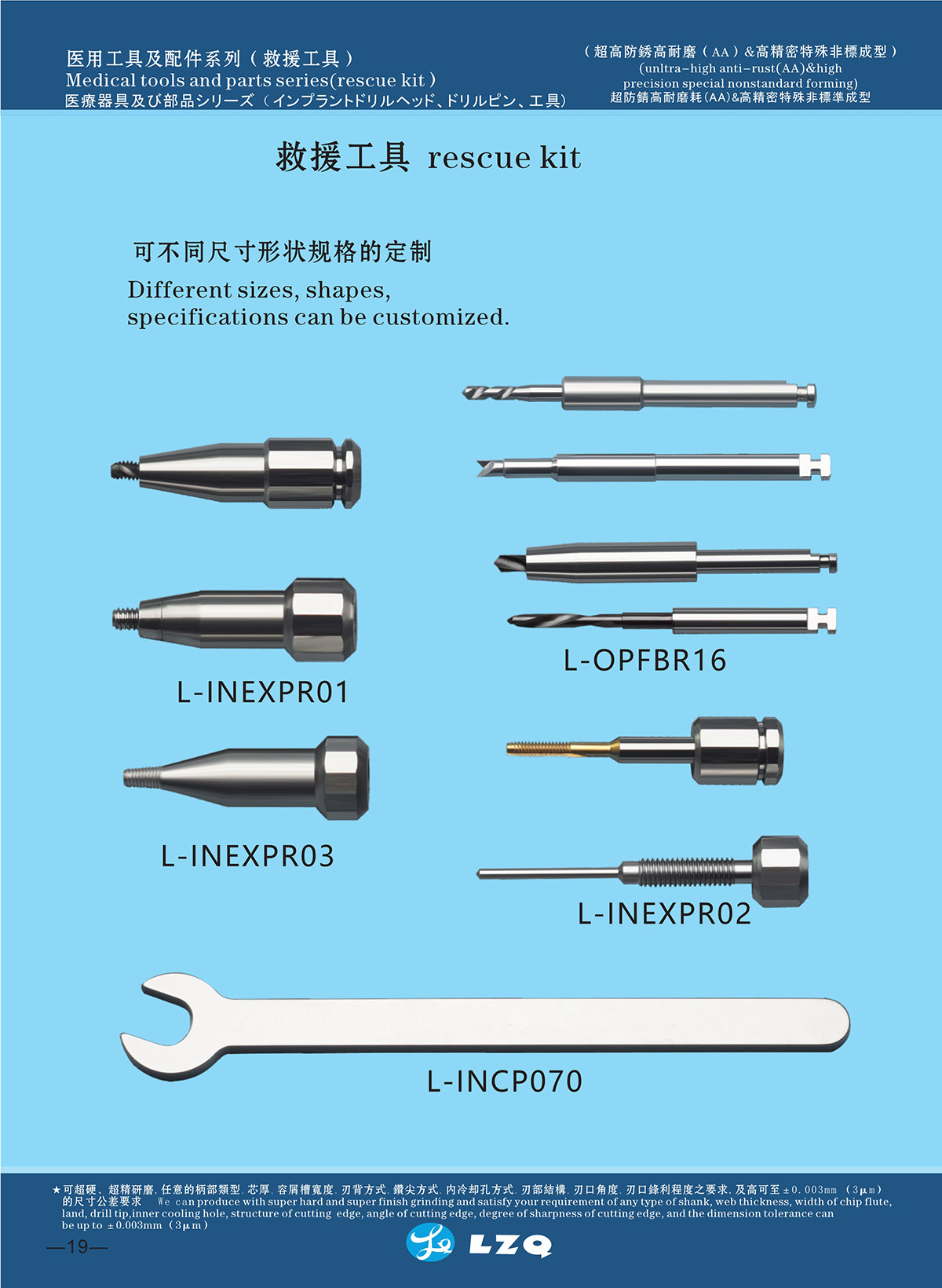

我们可以根据客户提供的任意图纸或者样品来生产任何牙科种植丝锥,而且性价比很高。

适应: 密质骨种植截骨术螺纹准备

配用: ISO电动附件

材料: 手术等级不锈钢

钻速: < 50 rpm

灭菌: 终端用户蒸汽灭菌

我们开发了可重复使用的丝锥,提供无与伦比的水平的强度和工作效率。对于外科医生的好处在于更快更精准的手术体验。可根据需要生产不同系统对应的螺纹结构和尺寸(与种植体对应匹配的螺距螺纹等),可以做锥度的,圆柱的以及各种形状的丝锥。

LZQ为特殊、非标、异型难加工类类产品进行中、大批量的生产,尽量不做单规格、小批量和标准的产品,因为单规格小批量生产无法摊销生产相应的高品质要求的工夹具、冶具、模具、砂轮的成本。而且如果没有准备好,制作出相应的工装夹具,生产出来的产品也不会很理想。当然,也要看产品的类别和规格来判定。而标准品的生产和一般的非标准品生产对我们公司的生产成本是差不多的,如φ12.0与φ12.218对我公司的生产成本是接近的,而对Sandvik、Widia……是有较大的差距。所以对于特殊、非标、异型、新产品的中、大批量生产,我们具有极大的竞争力,如果标准品是大批量订购的,我们也可以组织生产,但性价比和竞争力相对会较弱些,贵公司销售的利润空间也会较小些。

Tap for Maxillary Sinus Implantation,Surgical Taps for Tapered Implants

Characteristics

Application domain: for Implant

Material: Super-high rust-resistant high-hardness stainless steel, tungsten steel, ceramics, general stainless steel

Products Description

LZQ is an OEM factory for all kinds of dental implant tap, such as: Abutment/Transfer P25,Parallel Pin P37, Wrench P53, Screwdriver P79, Tap P152, Bone Fetcher P165,Lance Drill P172, etc. We can also produce a whole kit of tools for customers’ surgical cases.

We use the material of stainless steel.

We are capable to produce any taps according to drawings or samples provided by customer with a favorable cost-performance.

Indications: Osteotomy thread preparation for implants in dense bone

Compatibility: ISO latch type attachments

Material: Surgical grade stainless steel coating

Drill speed: < 50 rpm

Sterilization: Steam autoclave by end user

We have developed the reusable tap drill providing unrivaled levels of strength and working efficiency. The benefits for the surgeon include a faster, more precise tapping procedure and improved experience over the life of the tap. We can produce different structures and sizes of thread compatible with different system(thread pitch and thread compatible with implants, ect) according to your requirement.

LZQ often produces non-standard, special-shaped, high precision products which are difficult to machine in medium and big batch, but rarely in a small number for single dimension standard ones, because the cost of jig, fixture, mould and grinding wheel is quite high, and if without the mould, it is difficult to make an excellent item. However, it depends on the type and the dimension of the required products. Besides, in our company, the cost of standard products and that of the non-standard is similar, such as ?12.0 and ?12.218, but it is not for other companys, like Sandvik, Widia.This is why we are competitive in producing special, non-standard, special-shape goods. However, regarding to a big order, we also produce the standard products. But the cost-performance ratio and the competition are quite low, and also profit of the sale is lower for your company.