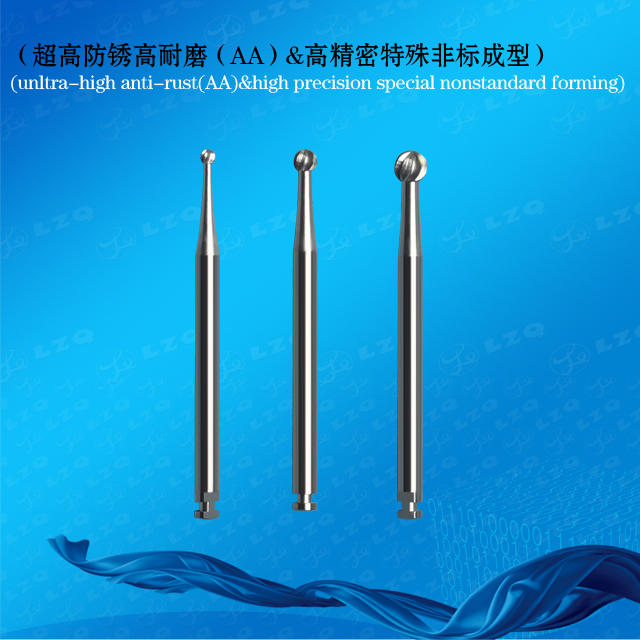

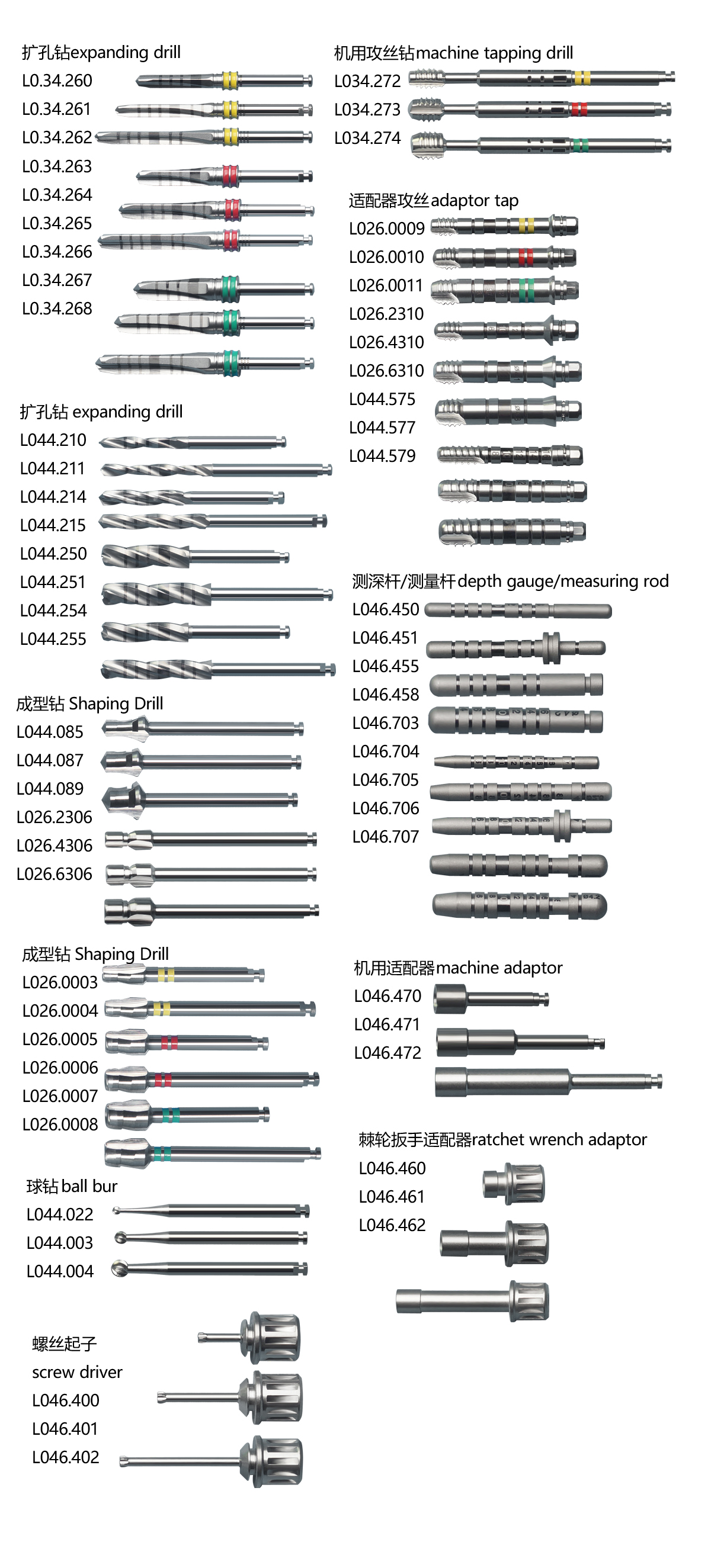

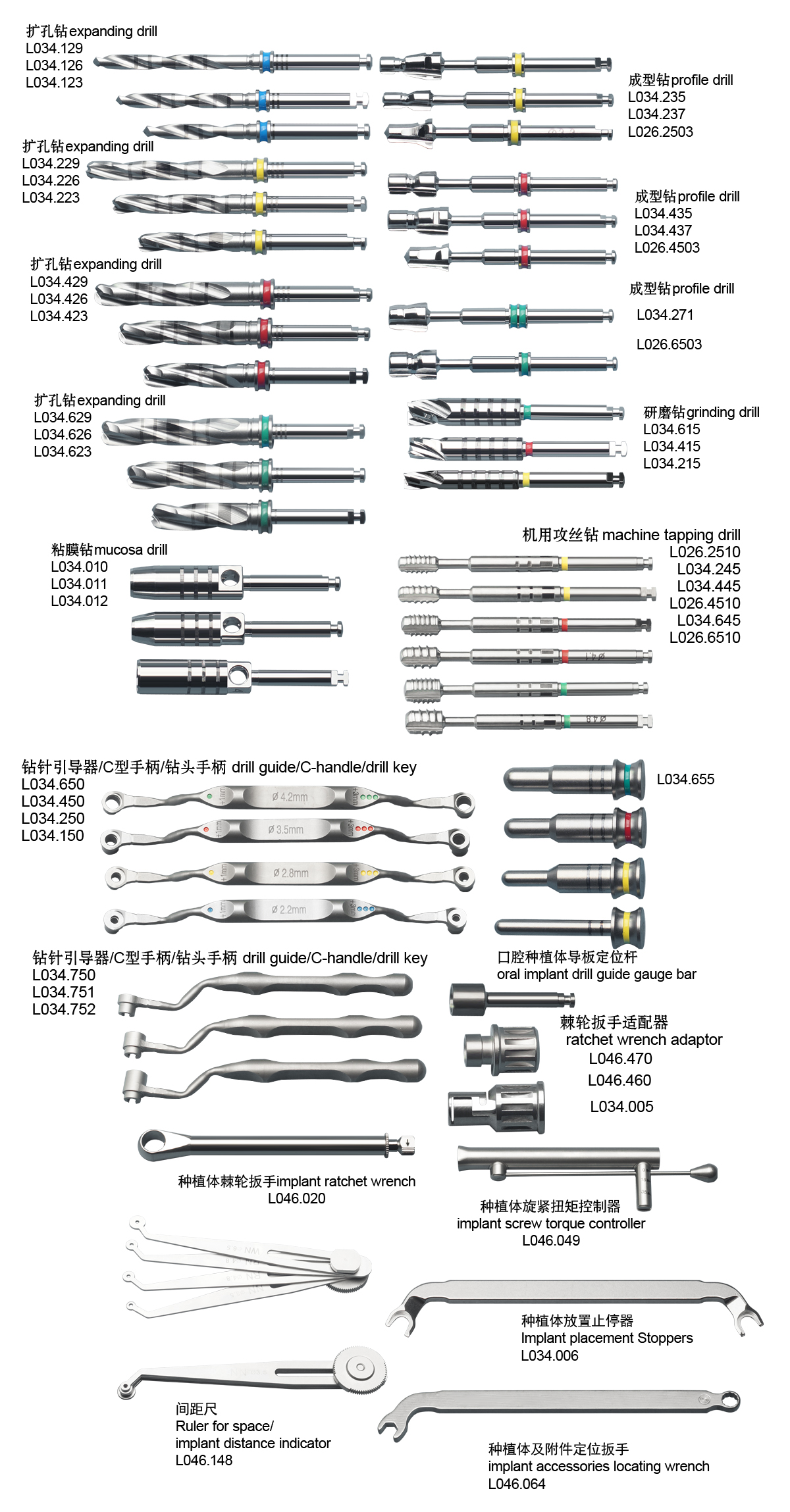

球钻,L044.003,L044.004,L044.022

球钻,L044.003,L044.004,L044.022

特性

应用领域: 用于医疗

材 料: 超高防锈高耐磨不锈钢,陶瓷

产品描述

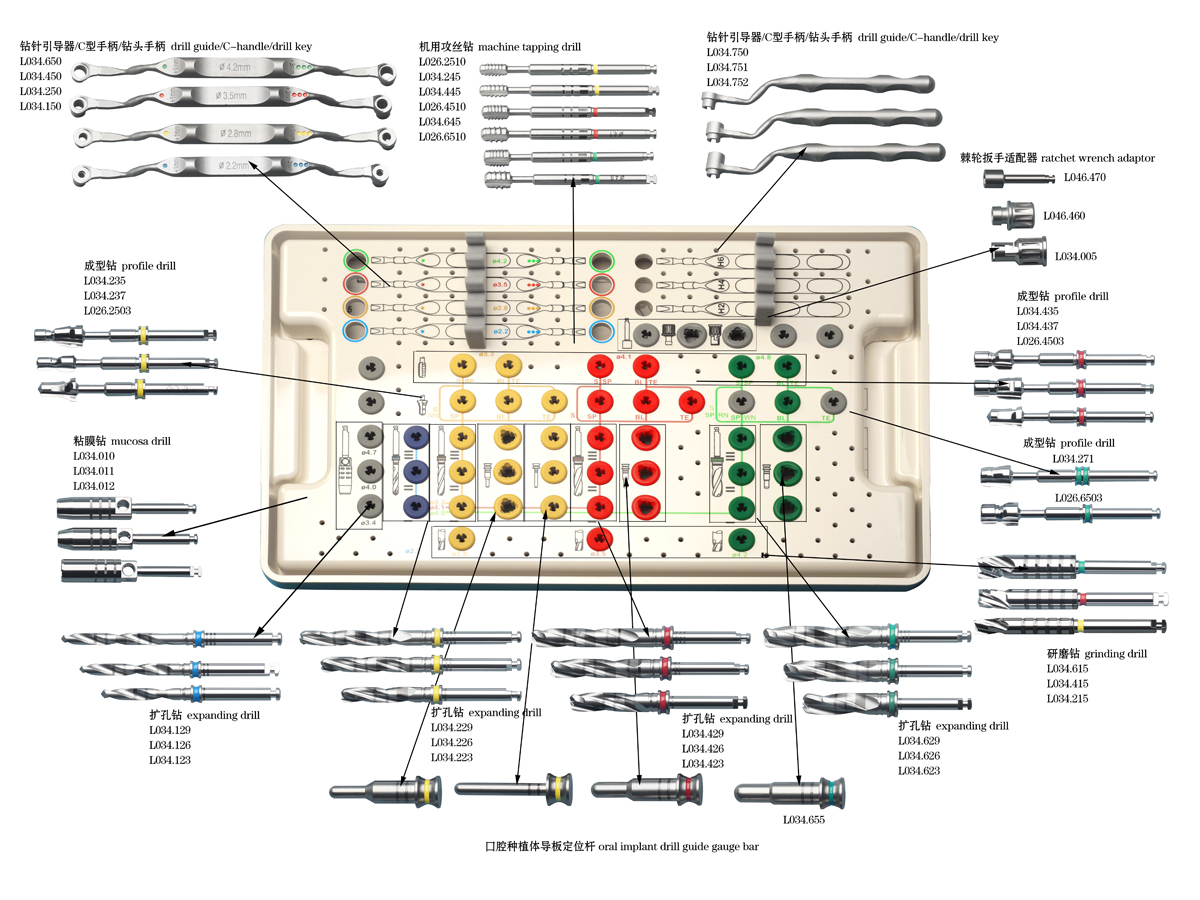

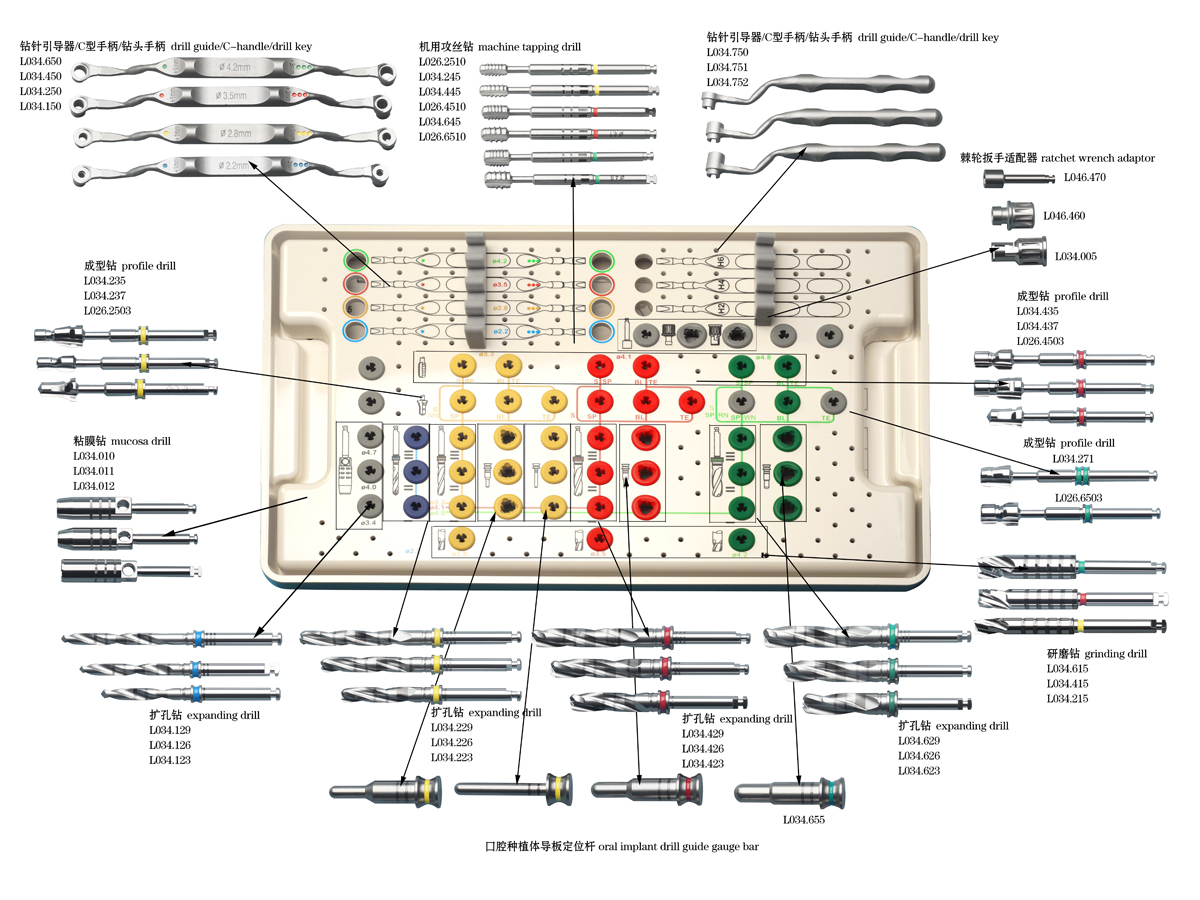

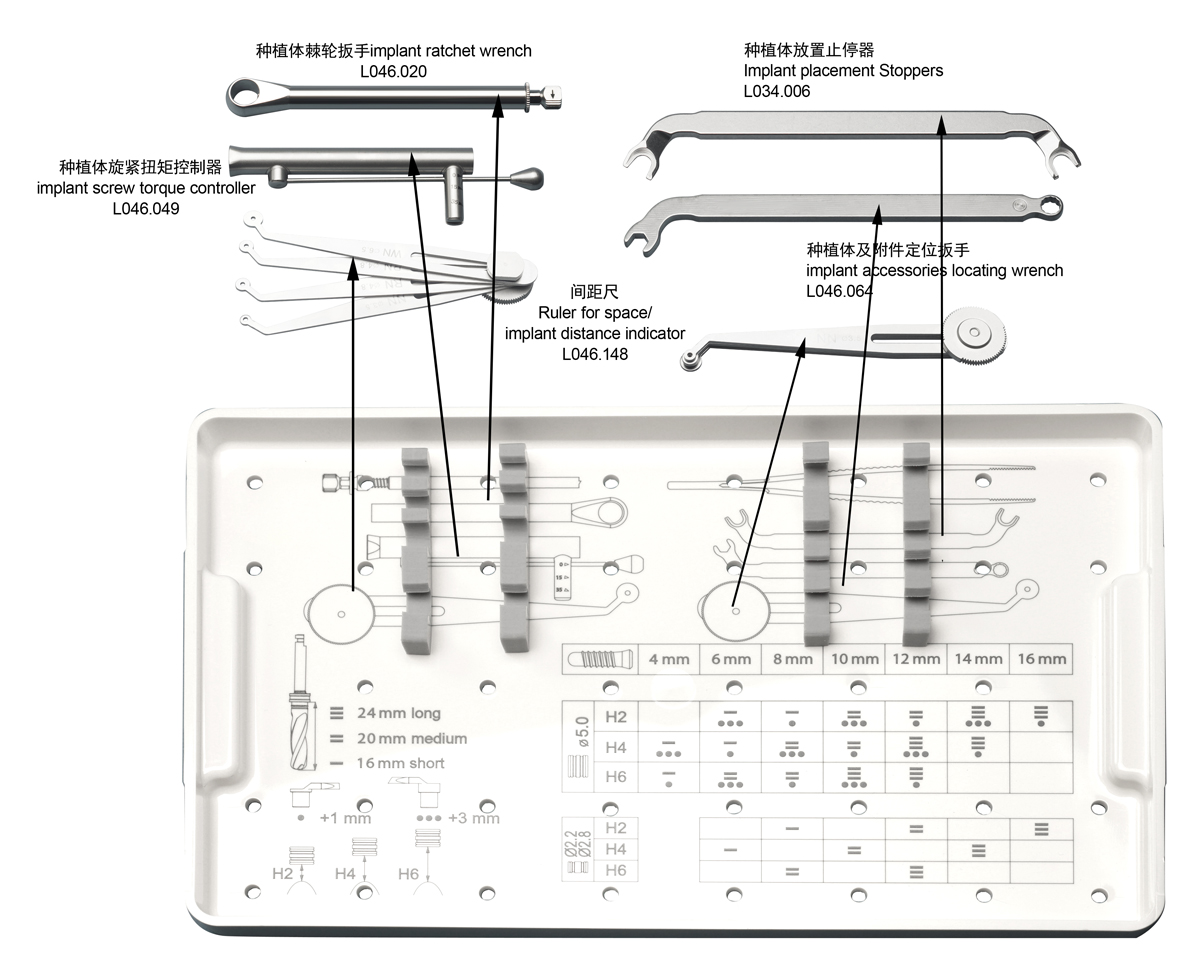

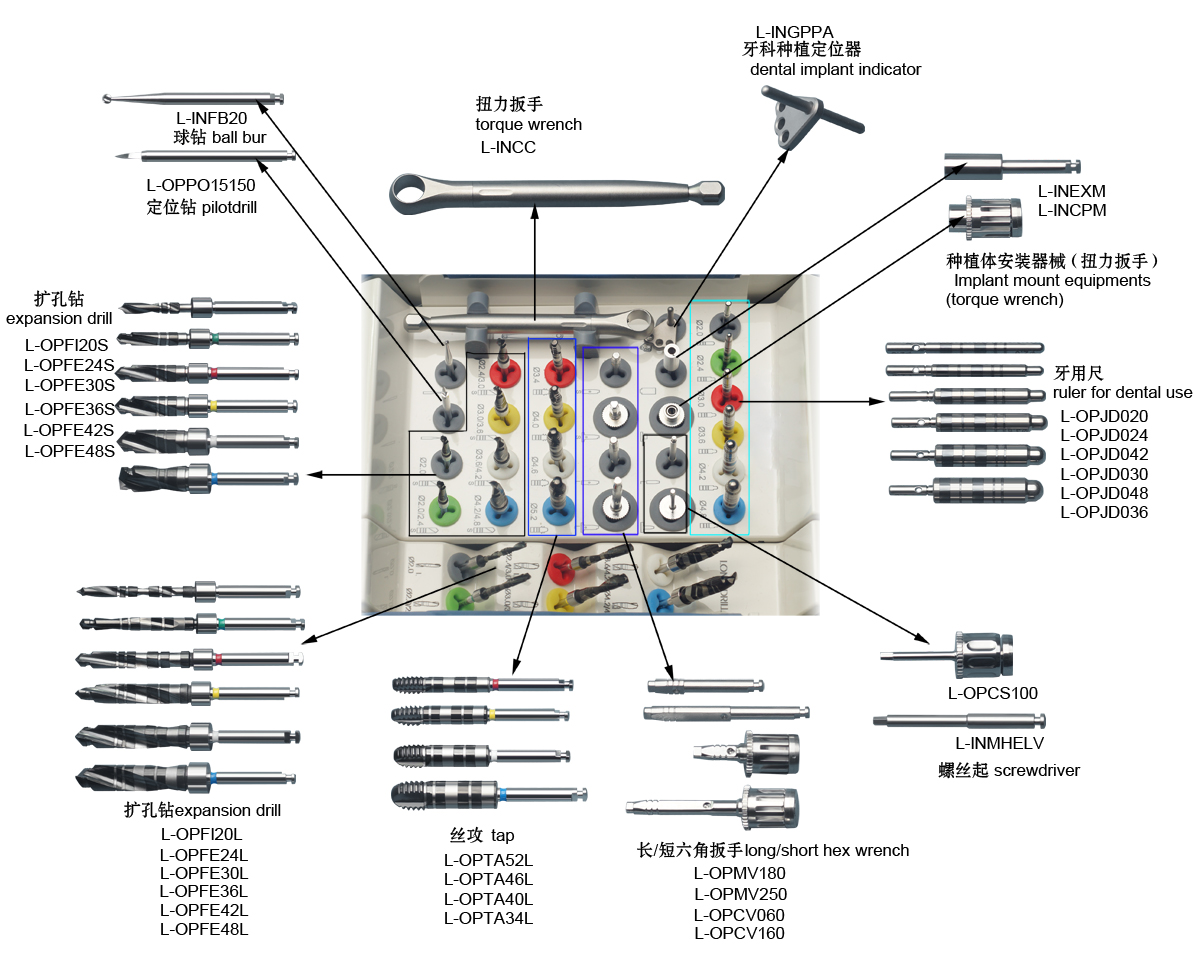

LZQ是一家生产各种牙科种植钻头的OEM代工工厂,例如,引导钻头P108,先锋钻 P172, 侧切钻P150, 螺丝起子P79, 压板P47, 延长器P44,等等。

- 2刃常用规格系列:

刃径Φ0.80mm~Φ5.50mm之间系列任意尺寸之规格

3刃常用规格系列:

刃径Φ0.80mm~Φ7.95mm之间系列任意尺寸之规格

4刃常用规格系列:

刃径Φ2.0mm~Φ7.95mm之间系列任意尺寸之规格

② 所有刃数常规刃长长可至55mm系列,总长可至65mm系列的任意阶梯、锥度角度、形状、锋利性要求加工的。

③ 规为10°~12°螺旋刃,可为锋利螺旋刃、挤光螺旋刃、钝化螺旋刃或前锋利后钝化螺旋刃等结构方式。

可依不同品牌、不同类型的植体形式、形状、结构等,高精密研磨成型对应的、匹配相

关的不同类型、形式、形状、结构的钻头、工具等等。

与LZQ配合可以依贵司的设计能力和想法,实现对医疗工具用途的推广,从而建立起属于贵司自己的工具、治具、零配件产品体系。只要有CAD或3D图或使用效果最好的实样或依自己想法用3D打印机打印样件,或者用木头刻制属于自己想法的产品并标注尺寸公差,岭之崎即可采用指定的国际一流高品质素材和先进综合的生产体系,强力高速CNC磨削加工中心(3DX技术)成型超硬,超精研磨,具有完美的刃口品质和高可至±0.0005mm(±0.5um)的尺寸公差,依图依样现生产,具有极强的性价比。

询盘请能提供使用效果最好的样品及参考页脚注明每种产品的详细要求、材料种类、尺寸公差、工件成品和半成品图纸、所用的设备、设备价值RMB(以判断其刚性及跳动等)、每月消耗的数量、原用产品类型及其不足之处?被加工材料及其硬度HRC?……

如有不足之处,请一定不吝指教:是易钝化?易崩刃?还是……?并能提供使用效果最佳——新的和旧的实样。

Characteristics:

Application domain: for medical

Material: Ultra high rust-proof and high wear-resistant stainless steel,ceramic

Products Description:

LZQ is an OEM factory that produces a variety of dental implant drills, for example, Guide Drill P108,Lance Drill P172, Side Cutting Drill P150, Screwdriver P79, Drill Key P47, Drill Extension P44, etc.

① 2-flute commonly-used specification:

Any size series of edge diameter between Φ0.80mm~Φ5.50mm

3-flute commonly-used specification:

Any size series of edge diameter betweenΦ0.80mm~Φ7.95mm

4-flute commonly-used specification:

Any size series of edge diameter between Φ2.0mm~Φ7.95mm

② The series with regular number of flutes, but cutting length up to 55mm and total length up to 65mm, processed with any step, taper angle, shape, sharpness requirements.

③ The conventional 10°~12°helical edge can be sharp, burnishing, passivated, or front-sharp but rear-blunt.

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shapes, structures, etc.

Cooperating with LZQ can help realize the promotion of the medical tools usages according to the design capabilities and ideas of your esteemed company, thus establishing your own tool kit, fixtures and spare parts product system. As long as you have CAD or 3D drawings, or samples with best using performance, or print the samples with a 3D printer, or use wood to engrave products with dimensional tolerances of your own ideas, LZQ can adopt a designated international first-class high-quality raw materials and advanced integrated production system, to do molding, superhard and ultra-fine grinding with the powerful high-speed CNC grinding machining center (3DX technology) according to drawings or samples, with perfect edge quality and dimensional tolerance up to ± 0.0005mm (± 0.5um), which is at a very good cost performance

When you make inquiry, referencing to the page footer, please provide samples with best work performance, and specify the detailed requirements, material types, dimensional tolerances, drawings of finished and semi-finished products, equipment used or equipment value (to judge its rigidity and runout, etc), monthly consumed qty, type of original samples and its inadequacies, the workpiece material to be processed by sample and its hardness HRC? ...

Any deficiencies, please do not hesitate to let us know: Is it easy to get passivated? Or tipping? Or something else? Please provide new and old samples--with the best working performance--for us to check and test.