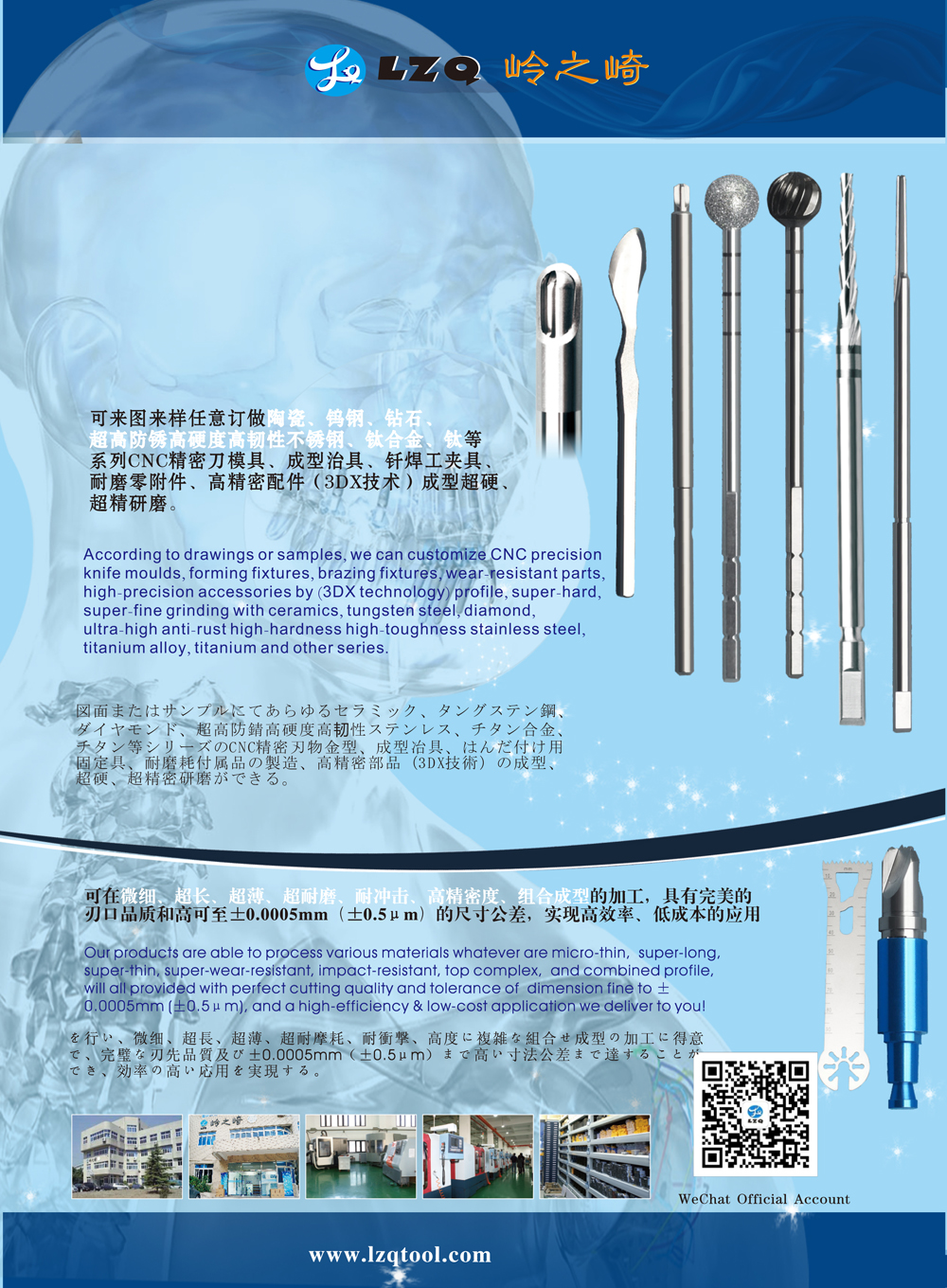

摩擦夹紧轮锉,摩擦夹紧火焰锉

摩擦夹紧轮锉,摩擦夹紧火焰锉

特性

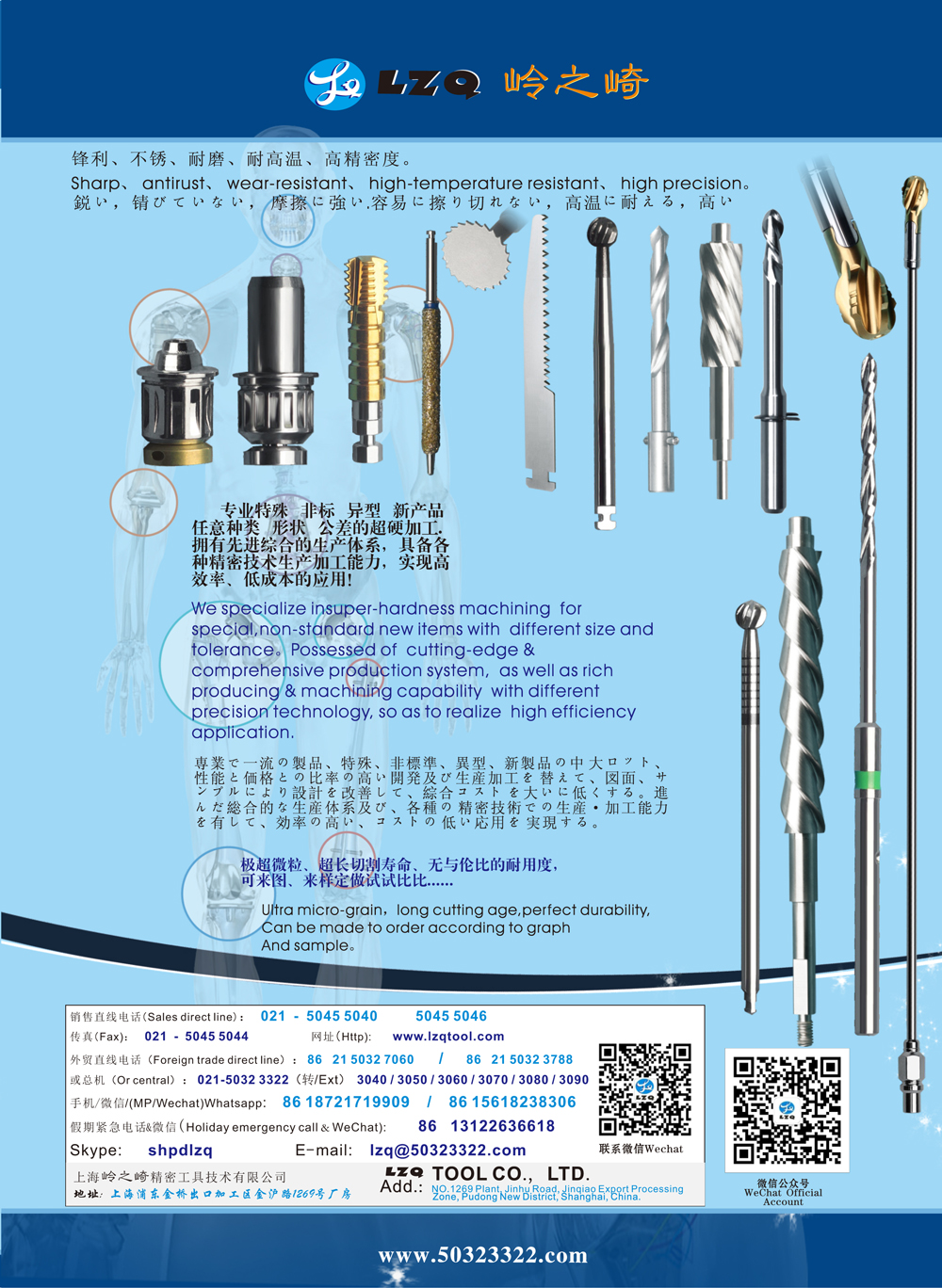

应用领域: 骨科手术, 颌面外科, 神经外科

材 料: 超高防锈高硬度不锈钢, 超高防锈高耐磨不锈钢, 金刚石,钨钢,SDC&CBNC

产品描述

LZQ是一家生产各种医用锉的OEM代工工厂,例如,切割锉/骨锉 P190, 钻套P31, 钻头096, 基台/转移杆P25, 骨锯 P250, 压板P47,内窥镜/关节镜刨刀 P259, 骨科钻针 P227,等等。我们也可以为客户生产成套手术工具。

(超高锐利型 & 耐磨型)

A:

头部加工材料等级:(SDC&CBNC)

1.一般锐利型、一般耐磨型(B)(常备常规)

2.超长锐利型、超高耐磨型(A&AA)(需批量定制)

B:

柄部材料等级:

1.常规标准防锈、高刚性(A)(常备常规)

2.高防锈、一般刚性(A)(常规常备)

3.超高防锈、高刚性(AA)(需批量定制)

可用陶瓷、钨钢、超高防锈高耐磨不锈钢(AA)、钛、钛合金等材料超精超硬研磨成型。

岭之崎可采用指定的国际一流高品质素材和先进综合的生产体系,强力高速CNC磨削加工中心(3DX技术)成型超硬,超精研磨,具有完美的刃口品质和高可至±0.0005mm(±0.5um)的尺寸公差,依图依样现生产,具有极强的性价比。

Friction grip wheel bur,Friction grip flame bur

Characteristics:

Application domain: dental, orthopedic surgery, maxillofacial surgery, neurosurgery

Material: Ultra-high anti-rust and high-hardness stainless steel ,Ultra high rust-proof and high wear-resistant stainless steel, diamond, carbide,SDC&CBNC

Products Description

LZQ is an OEM factory for all kinds of medical bur, such as Cutting Bur/Bone File P190, Drill Stopper P31, Drill Bit 096, Abutment/Transfer P25, Bone Saw P250 , Drill Key P47,Endoscopic/Arthroscopic Shaver blade P259, Bone Drill Point P227,etc. We can also produce a whole kit of tools for customers’ surgical cases.

(Super sharp type & Wear-resistant type)

A:

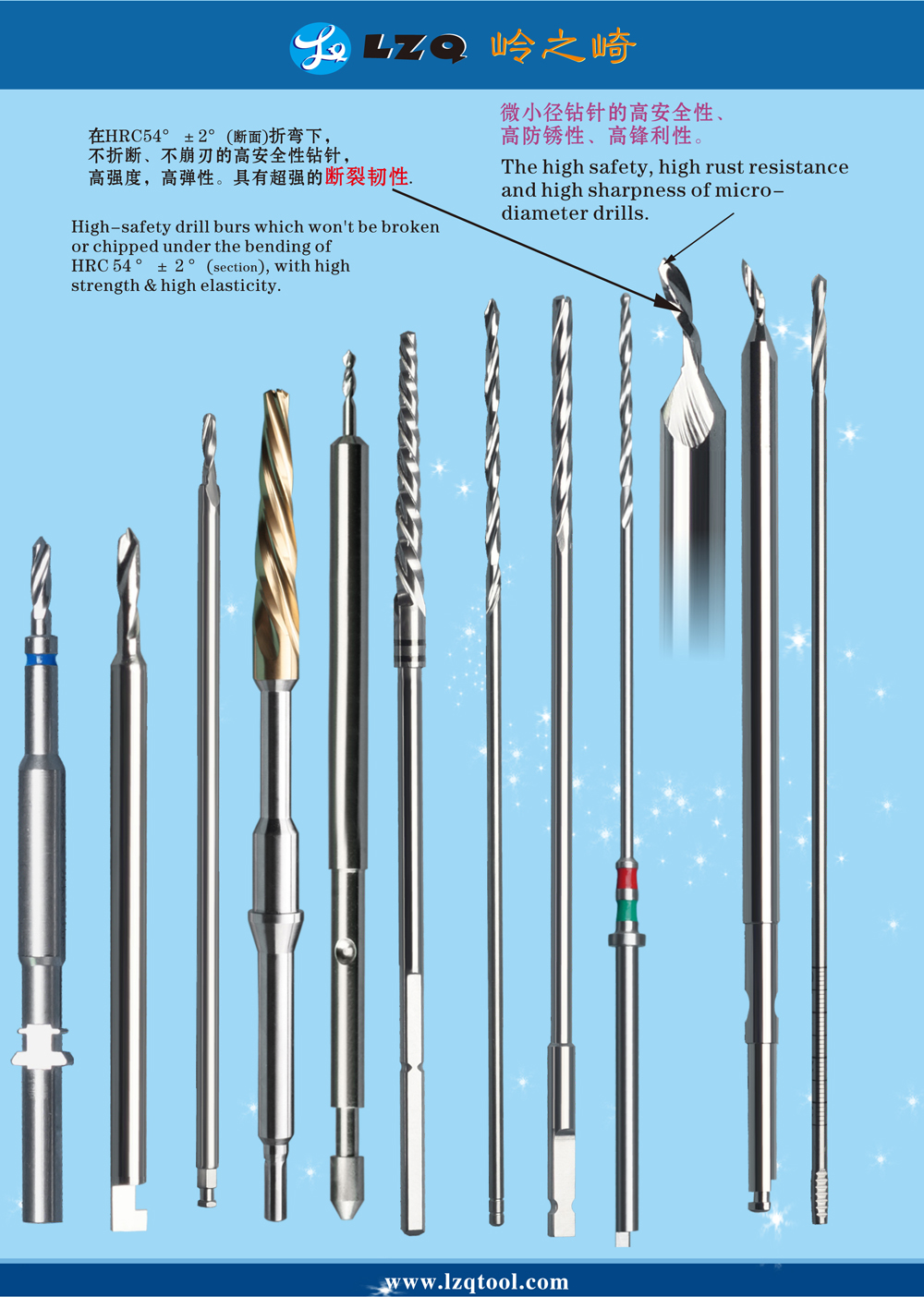

Head process material grade:(SDC&CBNC)

1. General sharp & general wear-resisting (B) (regularly in stock)

2. Super-long sharp & super-high wear-resisting (A&AA) (require mass customization)

B:

Shank material grade:

1. General anti-rust & high rigidity (A)(regularly in stock)

2. High anti-rust & general rigidity (A) (regularly in stock)

3. Super-high anti-rust & high rigidity (AA) (require mass customization)

They can be high precisely and high hard ground to mold with materials such as ceramic, carbide, superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, etc

LZQ can adopt a designated international first-class high-quality raw materials and advanced integrated production system, to do molding, superhard and ultra-fine grinding with the powerful high-speed CNC grinding machining center (3DX technology) according to drawings or samples, with perfect edge quality and dimensional tolerance up to ± 0.0005mm (± 0.5um), which is at a very good cost performance