骨嵴矫平器

骨嵴矫平器

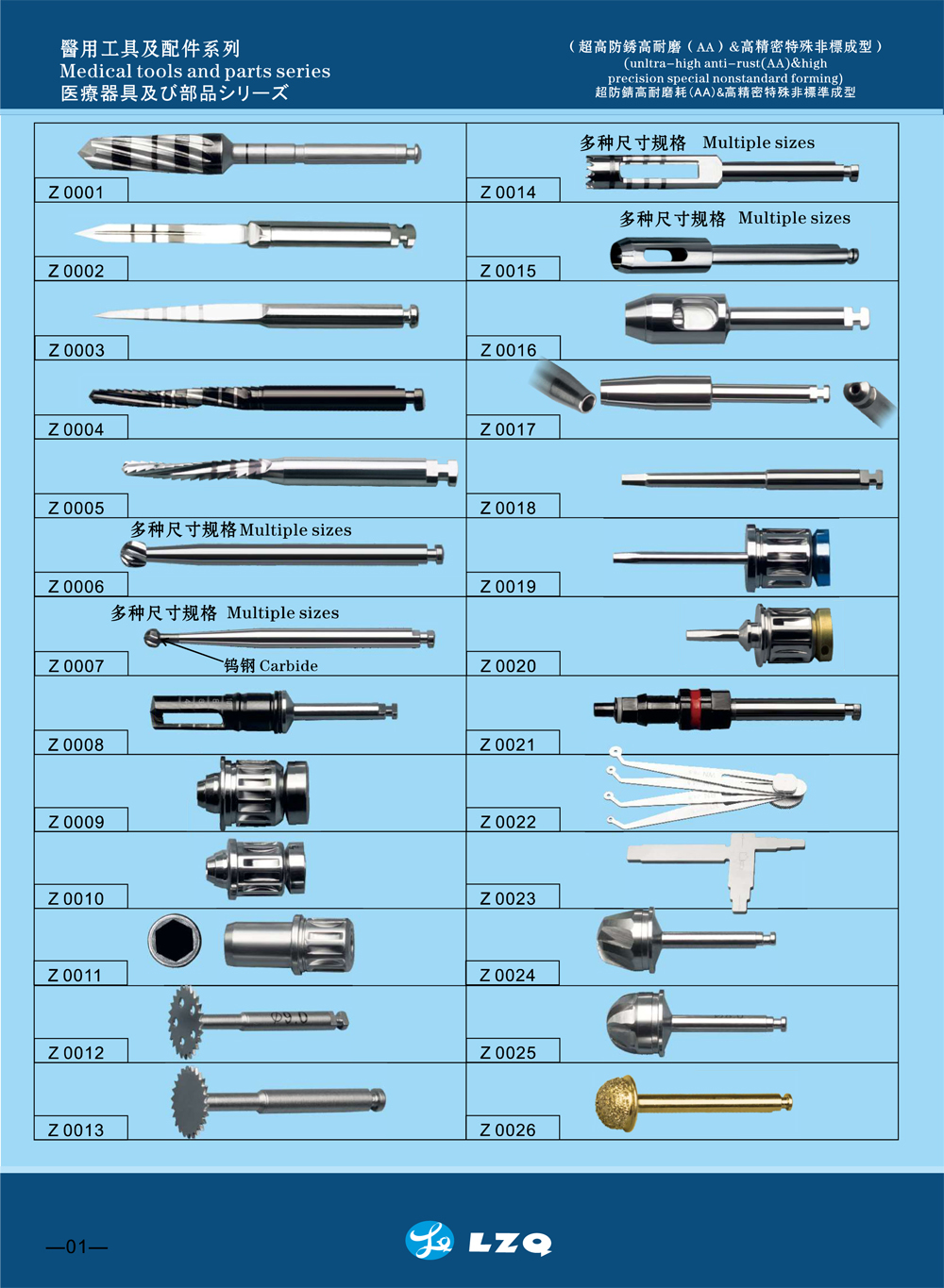

一, Product Information 产品信息

专业特殊、非标、异型、新产品、任意种类、形状、公差的超硬加工。

※ 如有类似,可FAX地址,来电索取图片中的样品及相关样本资料供参考(只限小金额)※

常年備存原材料、半成品、成品 3000萬 ~ 4000萬RMB周转的在庫品,依圖依樣現生產,具有極強的性價比……欢迎实地指导。

二,Products Description 产品说明

(超高防锈高耐磨(AA)&高精密特殊非标成型)

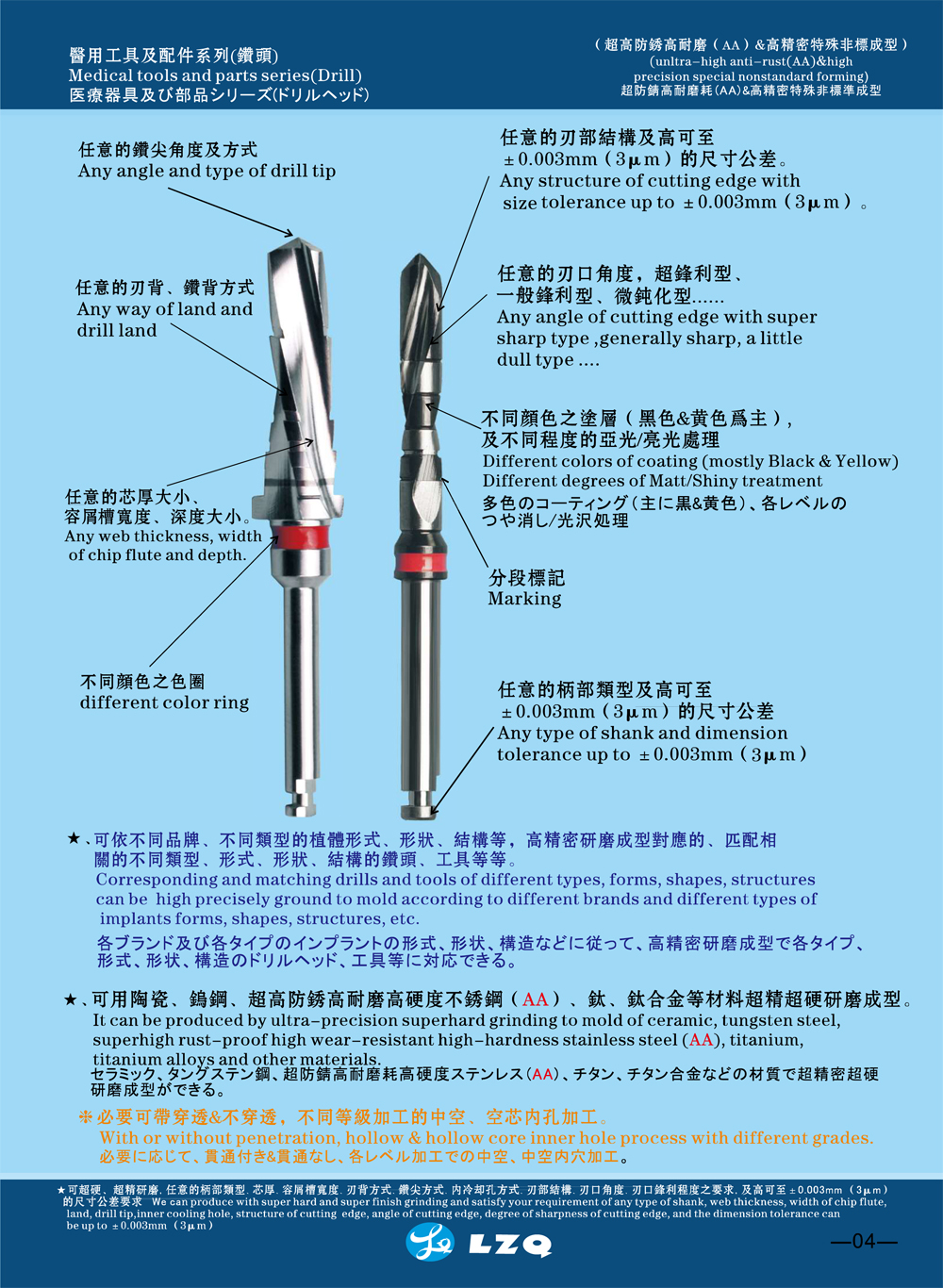

不同颜色之涂层(黑色&黄色为主),及不同程度的亚光/亮光处理

可超硬、超精研磨,任意的柄部类型、芯厚、容屑槽宽度、刃背方式、钻尖方式、内冷却孔方式、刃部结构、刃口角度、刃口锋利程度之要求,及高可至±0.003mm (3μm)的尺寸公差要求

可依要求生产不同刃部材料类型(陶瓷类、钨钢类、超高防锈高级品不锈钢类(AA)、钛及钛合金类、常规标准防锈高耐磨不锈钢(A)......等系列)

可依不同品牌、不同类型的植体形式、形状、结构等,高精密研磨成型对应的、匹配相关的不同类型、形式、形状、结构的钻头、工具等等。

可用陶瓷、钨钢、超高防锈高耐磨不锈钢(AA)、钛、钛合金等材料超精超硬研磨成型。

❈必要可带穿透&不穿透,不同等级加工的中空、空芯内孔加工。

1. 任意的钻尖角度及方式

2. 任意的刃背、钻背方式

3. 任意的芯厚大小、容屑槽宽度、深度大小。

4. 任意的刃部结构及高可至0.003mm(3um)的尺寸公差

5. 任意的刃口角度,超锋利型、一般锋利型、微钝化型……

6. 不同颜色之涂层(黑色&黄色为主),及不同程度的亚光/亮光处理。

※ 刃部加工等级:

AAA级: CNC超硬砂轮,镜面研磨任意形状之刃口,同心度,跳动,圆柱度≤0.003mm(3μm),可任意的刃口锋利程度。

AA级: CNC超硬砂轮,精研磨任意形状之刃口,同心度,跳动,圆柱度≤0.008mm(8μm),可任意的刃口锋利程度。

A级 : CNC超硬砂轮,一般研磨任意形状之刃口同心度,跳动,圆柱度 ≤0.012mm(12μm),可任意的刃口锋利程度。

B级 : CNC 车削加工+热处理+抛光处理,较差的刃口锋利性,同心度,跳动,圆柱度(0.10~0.20mm)(100/μm~200/μm)

三,Material / Characteristics 材质/特性

材料:

①超高防锈高耐磨不锈钢系列(AA)(常备常规)

②高抗冲击钨钢。

③超高耐磨高硬度钨钢。(超高耐用度,但较脆)

. ASTM440PH . Type 440C

. UNS S44004PH . ASTM F899 :

(超高防锈不锈钢AA) (淬硬处理HRC54°±2°断面)

超高防锈高耐磨高硬度、高抗冲击、高韧性不锈钢,具有极为优秀的防锈、耐腐蚀、耐磨耗(高硬度)性能及理想的抗冲击性能,优异的耐腐蚀能力接近 TYPE 304 Stainless 不锈钢,防锈性能接近于外科植入物用合金,无标示下5%中性盐雾实验( ASTM B117) 1000小时后无生锈。应用范围广,品质相当优秀及稳定,可生产极为复杂、高精密的柄部形状及成型的超锋利刃部结构。

适用高端医疗标准: AMS 5936 . MMPDS-01 . ASTM A693

ASTM A564 . ASTM F899-12

通过Vitro(细胞毒性)试验,验证材料不具有任何潜在的细胞毒性,因此能安全地与人类组织、体液或血液接触,符合所有相关过敏和皮肤刺激试验标准的要求。

UNS S42000

(超高防锈不锈钢A+) (淬硬处理HRC60°±2°断面)

高防锈、高锋利度、超高耐磨不锈钢,具有超高的耐磨耗(超高硬度)性能及高标准的防锈、耐腐蚀性能,相应一般不锈钢具有2~3倍的使用寿命,切削刃切割锋利性保持时间超长。无标示下5%中性盐雾实验( ASTM B117)符合FDA高标准时间约300小时后无生锈现象,如重复使用、手术后建议能及时清洁烘干处理。

应用范围广,耐磨性、锋利性表现优异,可生产极为复杂、高精密的柄部形状及成型的超锋利刃部结构。

Bone Crest Leveler

一, Product Information

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance.

※If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

※We keep around RMB 30~40 Million turnover stock articles such as raw material ,semi-products, finished products in ordinary year , we are capable to produce according to drawing or sample provided by customer, so as to present you a favorable cost-performance ratio…Welcome to visit our factory.

二,Products Description

LZQ is an OEM factory for all kinds of dental implant drills, such as Ceramic Drill P100, Drill with Inner Irrigation P121, Wrench P53, Screwdriver P79, Bone Fetcher P165, etc.

(unltra-high anti-rust(AA)&high precision special nonstandard forming)

Different colors of coating (mostly Black & Yellow),Different degrees of Matt/Shiny treatment

Material of cutting edge:

1.Ultra-high anti-rust high wear-resistant stainless steel(AA)(HRC54°±2°Section)(regular stock)

2.General anti-rust high wear-resistant stainless steel(A)(HRC45°~64°Section) series

3.Titanium and Titanium alloy (HRC35°~42°) series

4.Ceramic(HRA85°~94°)series,(HRC67°~84°) series

5.Carbide(HRA81°~94°) series,(HRC60°~84°) series

Chip collector, Bone deposition drill and reamer series commonly used for skeletal fragment collection and bone powder accumulation to the crest as reference:

Regular stock material: Ultra-high anti-rust & high wear-resistant stainless steel (AA)(HRC54°±2°Section)

Deep groove to top, chip accumulation to the crest. (It can be with black, yellow, full matt, full shiny, partial matt + partial shiny and other surface treatment)

① 2-flute commonly-used specification: Any size series of edge diameter between Φ0.80mm~Φ5.50mm

3-flute commonly-used specification: Any size series of edge diameter betweenΦ0.80mm~Φ7.95mm

4-flute commonly-used specification: Any size series of edge diameter between Φ2.0mm~Φ7.95mm

② The series with regular number of flutes, but cutting length up to 55mm and total length

up to 65mm, processed with any step, taper angle, shape, sharpness requirements.

② The conventional 10°~12°helical edge can be sharp, burnishing, passivated, or

front-sharp but rear-blunt.

1. Commonly-used edge diameter: any size series between Φ0.80mm~Φ7.95mm

2. Conventional cutting length up to 55mm series,and total length up to 65mm, processed with any step, taper angle, shape, sharpness requirements

We can produce with super hard and super finish grinding and satisfy your requirement of any type of shank, web thickness, width of chip flute,land, drill tip,inner cooling hole, structure of cutting edge, angle of cutting edge, degree of sharpness of cutting edge, and the dimension tolerance can be up to ±0.003mm (3μm)

The cutting edge can be produced with different materials (ceramic, carbide, superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, generally anti-rust and high wear resistant stainless steel (A) ... series)

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shapes, structures, etc.

They can be high precisely and high hard ground to mold with materials such as ceramic, carbide, superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, etc

With or without penetration, hollow & hollow core inner hole process with different grades.

Any angle and type of drill tip

Any way of land and drill land

Any web thickness, width of chip flute and depth.

Any structur of cutting edge with size tolerance up to 0.003mm(3um).

Any angle of cutting edge with supper sharp type, generally sharp, a little dull type…

Different colors of coating(mostly black & yellow), different degress of matt/shiny treatment

※ Cutting edge machining grades:

Class AAA: CNC super hard grinding wheel, mirror surface grinding for any shape of cutting edge.Concentricity, runout, cylindricity≤0.003mm(3μm),any sharpness of cutting edge.

Class AA: CNC super hard grinding wheel, finish grinding for any shape of cutting edge.Concentricity, runout, cylindricity ≤0.008mm(8μm),any sharpness of cutting edge.

Class A: CNC super hard grinding wheel, general grinding for any shape of cutting edge.Concentricity, runout, cylindricity≤0.012mm(12μm),any sharpness of cutting edge.

Class B: CNC lathe work + heat treatment + polishing treatment, worse sharpness of cutting edge.Concentricity, runout, cylindricity(0.10~0.20mm)(100/μm~200/μm).

三,Material / Characteristics

Characteristics

Application domain: For implantology

Material:

. ASTM440PH . Type 440C

. UNS S44004PH . ASTM F899 :

(Ultra-high rust-proof stainless steel AA) (hardened HRC54 ° ± 2 ° Section)

Ultra-high anti-rust & high wear-resistant , high hardness, high impact, high toughness stainless steel, with excellent anti-rust capability, corrosion resistance, wear resistance (high hardness) performance and ideal impact resistance.. Its excellent corrosion resistance is comparable to TYPE 304 Stainless steel; and its rust resistance is closer to alloy for surgical implant. Unmarked, with 5% Neutral salt spray test (ASTM B117), it doesn't rust after 1000 hours. Wide range of applications, quite good and stable quality, which can be used to produce extremely complex, high-precision shank shapes and profile ultra-sharp edge structures.

Applied for high-end medical standard: AMS 5936 . MMPDS-01 . ASTM A693

ASTM A564 . ASTM F899-12

The Vitro (cytotoxicity) test verifies that the material does not have any potential cytotoxicity and therefore can safely contact human tissue, body fluids or blood, and meets all relevant allergy and skin irritation test standards.

UNS S42000

(Super-high rust-proof stainless steel A+) (hardened HRC60°±2°Section)

Ultra-high anti-rust, high-sharpness and super-high wear-resistant stainless steel, with super-high wear resistance (super high hardness) performance and high standards of rust and corrosion resistance. It has a service life of 2 ~ 3 times longer than that of general stainless steel. The cutting edge keeps for a super-long time of cutting sharpness. Unmarked, with 5% Neutral salt spray test (ASTM B117), it doesn't rust after 300 hours, which meet FDA high standard. If for repeated use, it is recommended to clean and

dry it in time after every surgery.

Wide range of applications. With excellent abrasion resistance and sharpness, it can be used to produce extremely complex, high-precision handle shapes and formed super-sharp edge structures.

Contact

LZQ TOOL CO., LTD.

Sales hot-line:+0086-21-50323788 / +0086-21-50327060

Fax:+0086-21-50455044

Website: https://www.lzqtools.com

Whatsapp/wechat: 8615618238306 / 8618721719909

skype:shpdlzq / lzqtool9

ADD:NO.1269 Factory,JinHu Road,JinQiao,Export processing Zone,PuDong,ShangHai,China