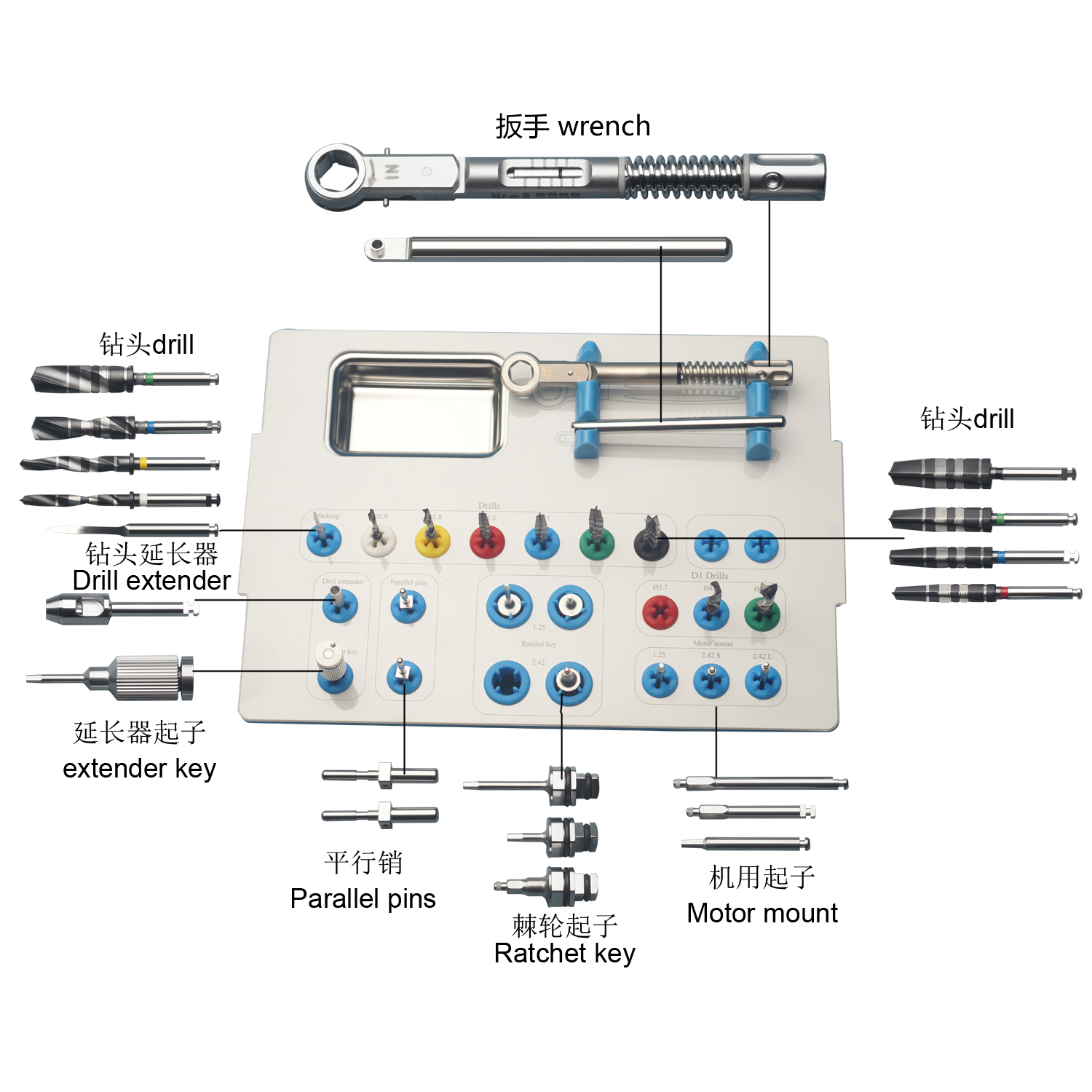

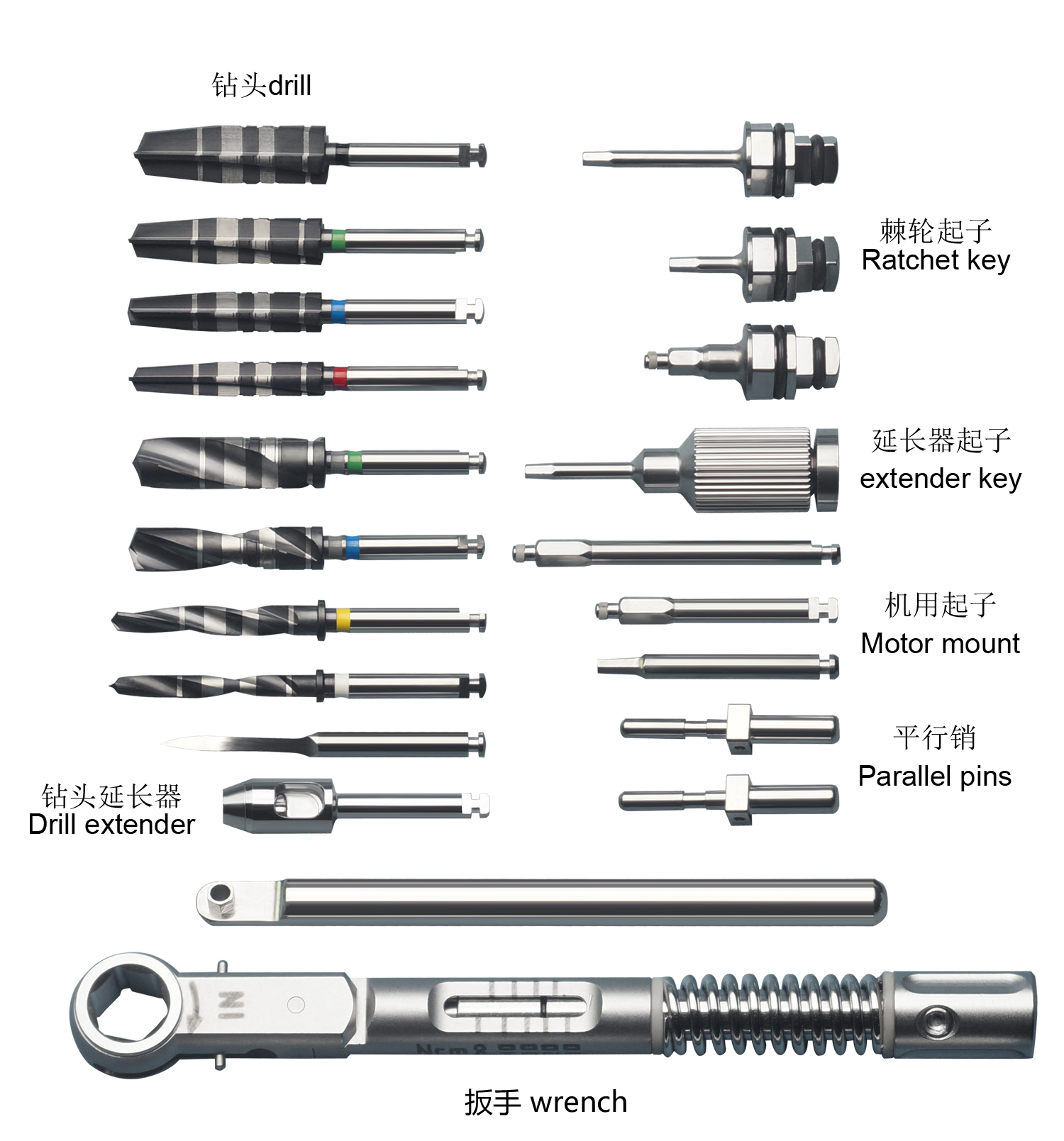

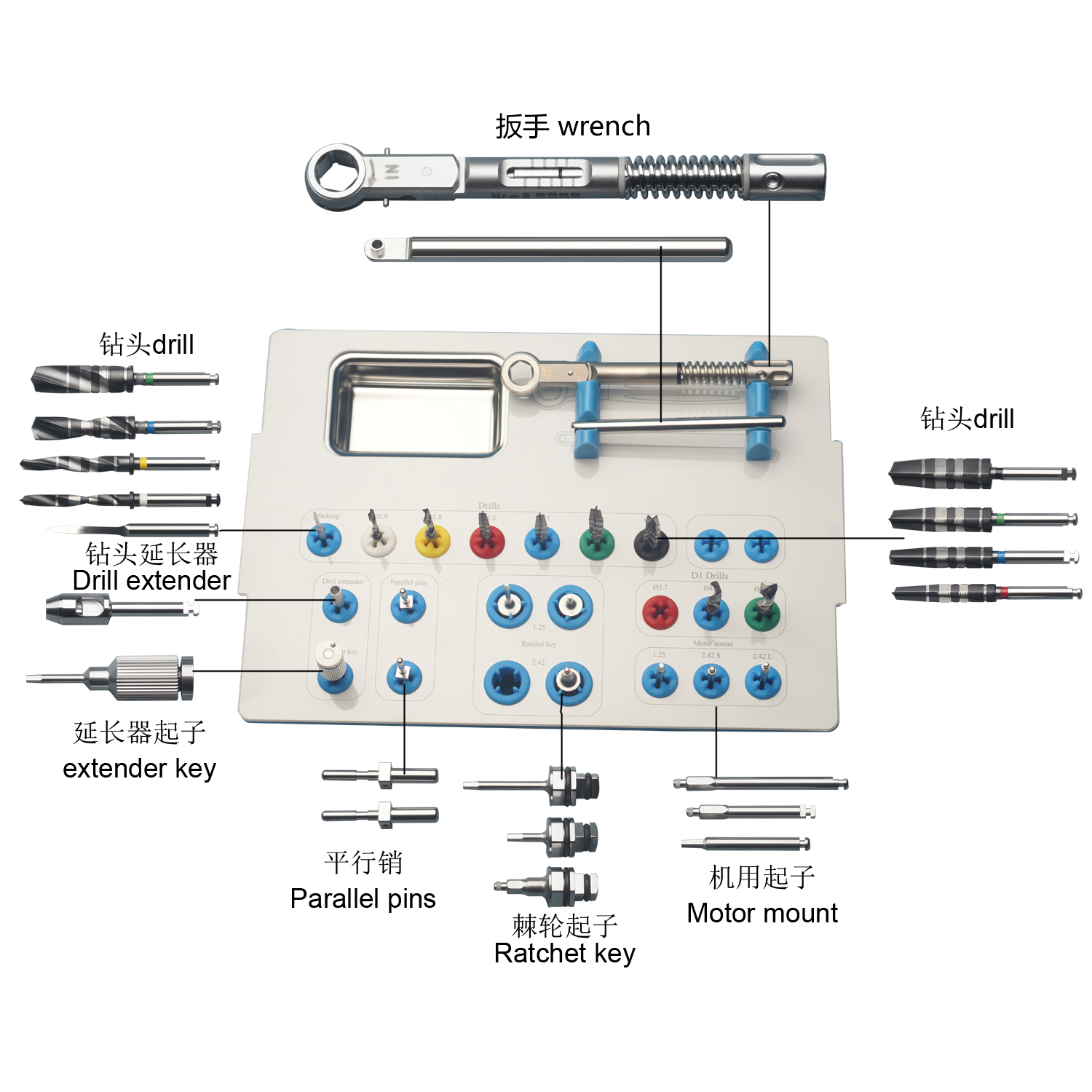

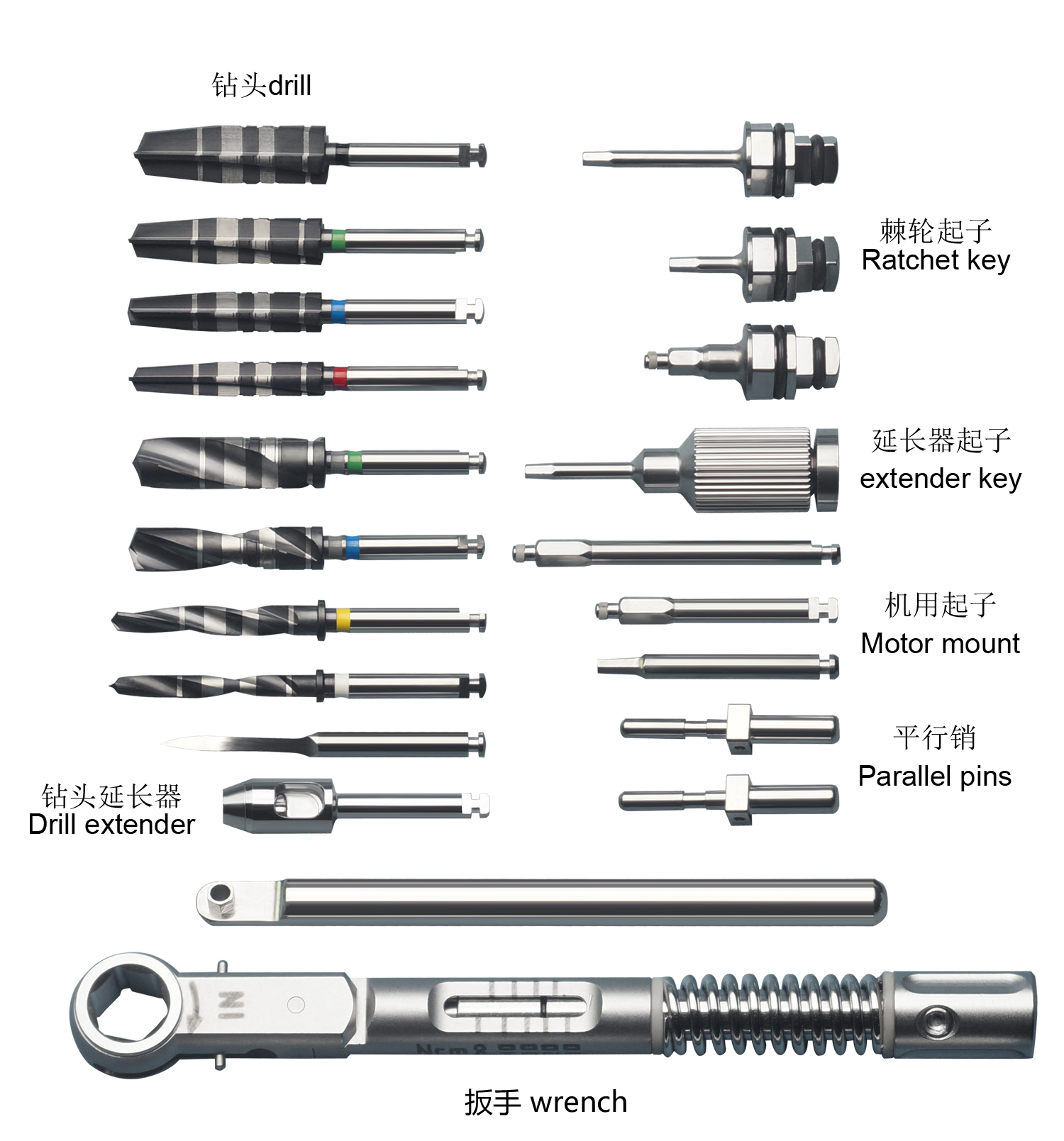

棘轮起子,延长起子,机用起子

棘轮起子,延长起子,机用起子

特性

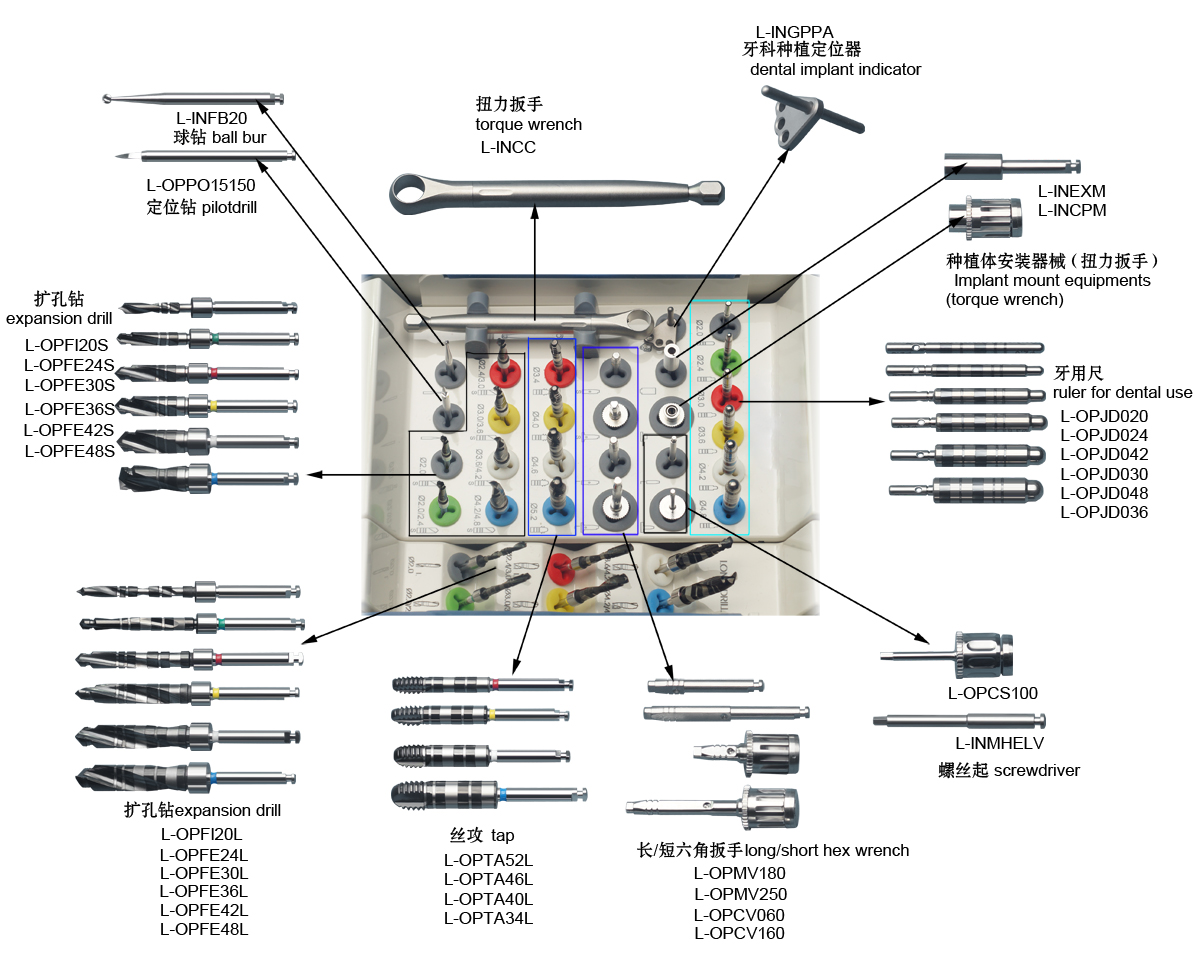

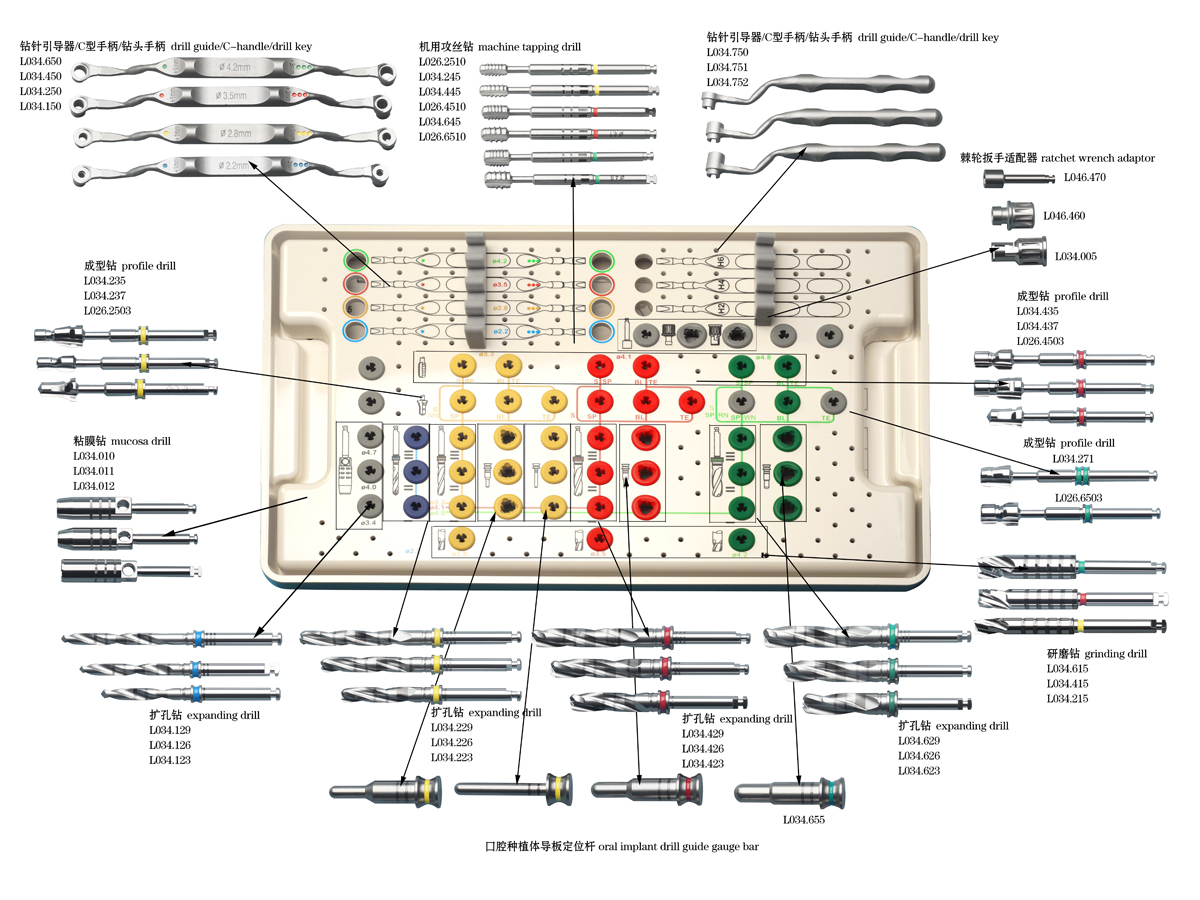

应用领域: 用于牙科种植

材料:手术不锈钢

类型: 手用或机用

产品描述:

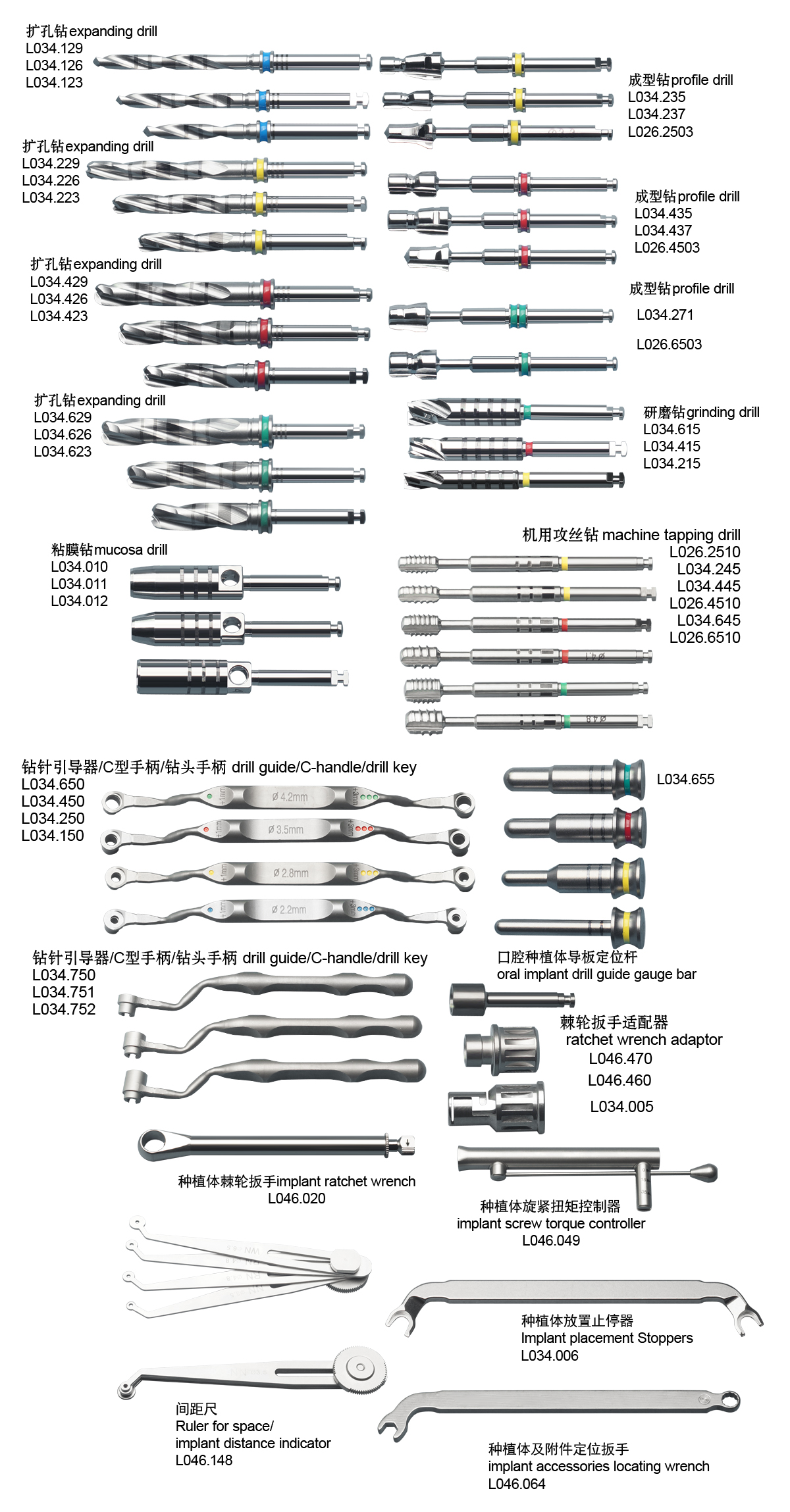

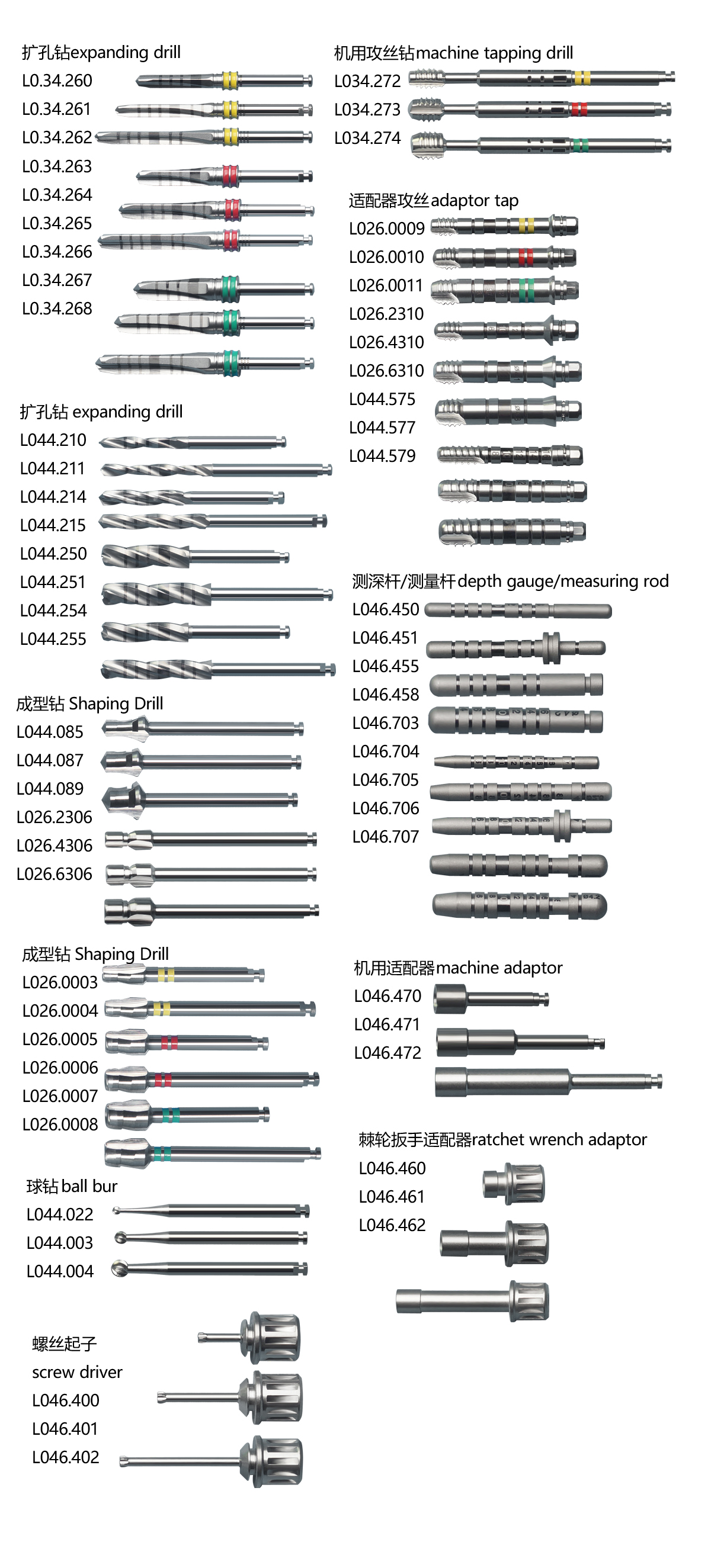

LZQ是一家生产各种牙科种植螺丝起子的OEM代工工厂,例如,螺丝起子P79, 钻套P31, 侧切钻P150, 牙术 P175, 颅骨铣刀 P216, 骨锯 P250,等等。我们也可以为客户生产成套手术工具。

我们可以根据客户提供的任意图纸或者样品来生产任何牙科种植起子,而且性价比很高。

不同类型起子的不同功能:

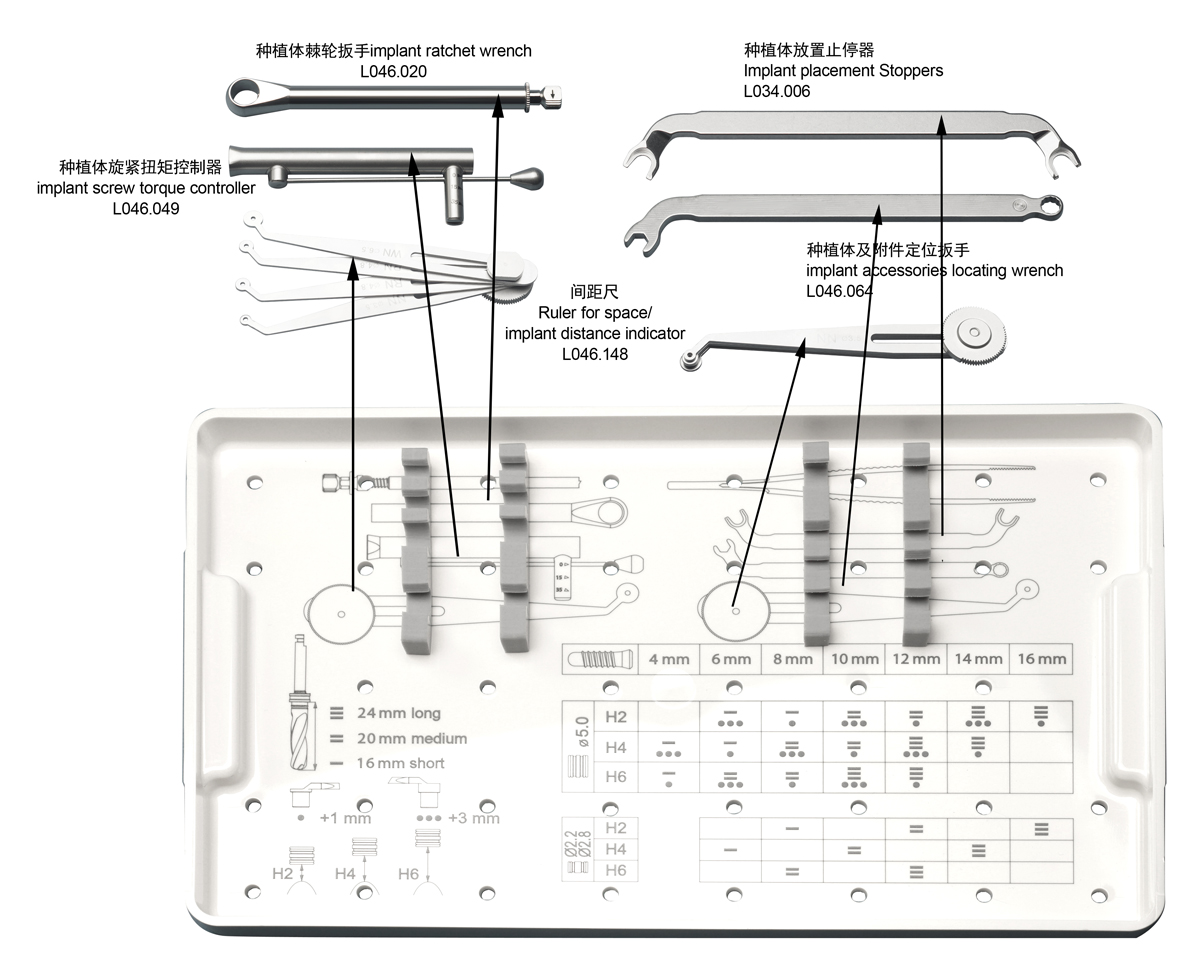

1. 扭力扳手连接,调整扣留力

2. 棘轮扳手连接,延长简易安装长度,用于输入手动扭力。

3. 尖端夹持功能: 止停设计用于防止夹持部位破裂,并防止手术中杂质如血痕的产生。

手动紧固固定螺丝,各种种植体。注意最大扭力以避免意外破裂。一些带岔开六角以更好紧固和移动螺丝,处理种植体和愈合帽的覆盖螺丝。

槽,镭标和色圈用于连接时区分,可以根据客户任意要求定做。

涂层: 如果客户需要也可以做.

坚固的设计和高级的材料保证工作效果,提供种植修复过程中可能出现的问题的完整解决方案。

(超高防锈型(AA)&常规标准防锈型(A)&可超高精密加工)

材料:

①超高防锈高耐磨不锈钢系列(AA)(HRC54°±2°断面)(常规常备)

②常规标准防锈高耐磨不锈钢系列(A)(HRC45°~64°断面)

③有必要在超高精研磨下,起子处精度可至±0.002mm(±2um)

可定制任意形状的梅花起子,公差高可至±0.002mm(依螺钉实样实配)

目前LZQ在高硬度用、高耐磨用、高耐冲击用、高温合金、耐热合金、镍钒钛合金铸铁、不锈钢、钴基镍合金、钛合金……等难加工材料类的各类产品的生产加工上表现突出,并取得较大的成绩,常用进口材料有HRF10/K15A(超精加工→半精加工、高硬度用)、MR11(精加工→半粗加工、难加工材料用)、H10F/PR40(泛用型、通用型加工用)、VAR201(要求高耐冲击、高抗崩性加工用)、ASP60A(HSS-Co10)、SKH57C(HSS-Co)、ASTM440PH……近300种材种材料。

Characteristics

Application domain: for dental implantology

Material: surgical stainless steel

Type: hand or machine

Products Description

LZQ is an OEM factory for all kinds of dental implant screwdrivers, such as Screwdriver P79, Drill Stopper P31, Side Cutting Drill P150, Osteotome P175, Cranial Bur P216, Bone Saw P250, ect. We can produce a whole kit of tools for customers’ surgical cases.

We are capable to produce any size and shape of dental implant drivers according to drawings or samples provided by customer with a favorable cost-performance.

Different functions of different types:

1. Torque driver connection, to adjust the retention force.

2. ratchet wrench connection, for extension of simple mount length, and use in case of inputting hand-torque.

3. Tip holding function: stopper designed for the prevention of fracture of the holding part and occurrence of foreign matter such as blood stain during surgery

To manually tighten fixing screws, to close abutment. To tighten all kind of implants. Safeguard maximum torque to avoid possible fracture. Some with diverging hex for better screw tightening and transport; Handling cover screws for Implants and Healing Cap.

Grooves, laser mark and color ring: designed for checking during the connection, can be customized according to your specific requirement.

Coating: can also be done if you need.

Heavy duty with robust design and proven material, complete solution for critical problems which might occur in the prosthetics process

(Super-high anti-rust (AA)& General anti-rust(A)&with super-high precision process)

Material:

①Super-high anti-rust high wear resistance stainless steel

series(AA)(HRC54°±2°Section)(regularly stock)

②General anti-rust high wear resistance stainless steel series(A)(HRC45°~64°Section)

③If necessary, with super-high finish grinding, the driver finish could reach ±0.002mm.

we can customize any shape of Torx driver, the tolerance can be up to±0.002mm(to match the screw samples accordingly)

At present , LZQ is good at producing tools for high-hardness, high wear-resistant andhigh impact-resistant products, like High-temperature alloy, Heat-resisting alloy, Vanadium-titanium alloy of nickel iron, Stainless steel, Cobalt-based nickel alloy, Titanium alloy or other items, made of difficult-processing material, and have done a good job. There are about 300 kinds of material we often use, like the imported ones, HRF10/K15A(for application from super-finish machining to semi-finish machining and for high-hardness processing), MR11(for application from finish machining to semi-rough machining, and the use of hard-processing material ), H10F/PR40(for widely-used and ordinary processing application), VAR201(for high wear-resistant and chipping-resistant application), ASP60A(HSS-Co10), SKH57C(HSS-Co), ASTM440PH…totally about 300 kinds of material.