儿科头颅铣刀 开颅手机用波形螺旋钻 显微手术用电动高速钻

应用领域: 用于颌面外科、骨科手术

材 料: 超高防锈高耐磨不锈钢

儿科头颅铣刀 开颅手机用波形螺旋钻 显微手术用电动高速钻

特性

应用领域: 用于颌面外科、骨科手术

材 料: 超高防锈高耐磨不锈钢

LZQ是一家生产各种颌面外科钻和骨钻的OEM代工工厂,例如,骨科钻头P228,颅骨铣刀P216,铣刀/扩髓钻P219,等等。我们也可以为客户生产成套手术工具。

我们使用不锈钢材料。

我们可以根据客户提供的任意图纸或者样品来生产任何颌面外科钻头,而且性价比很高。

产品描述

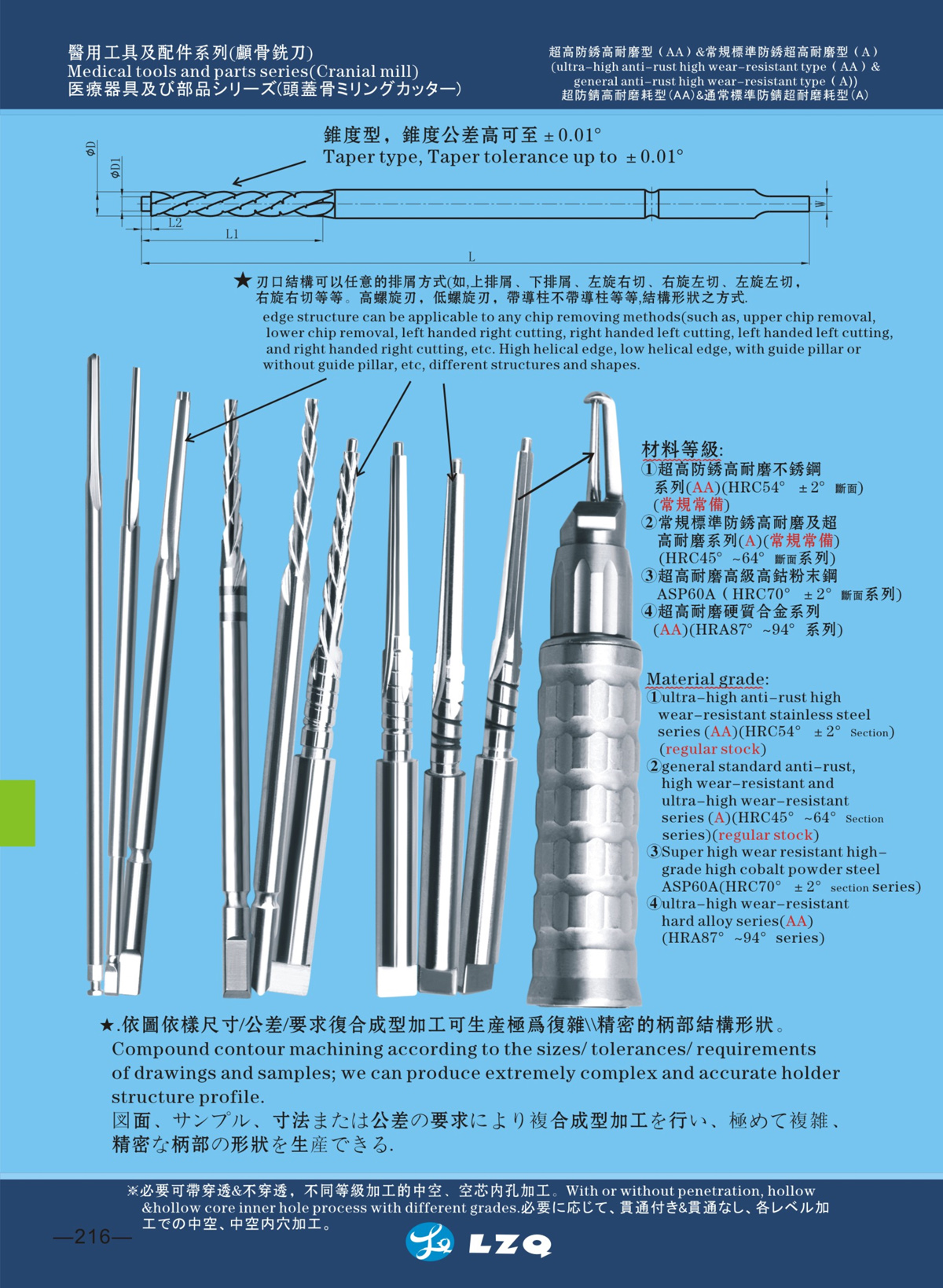

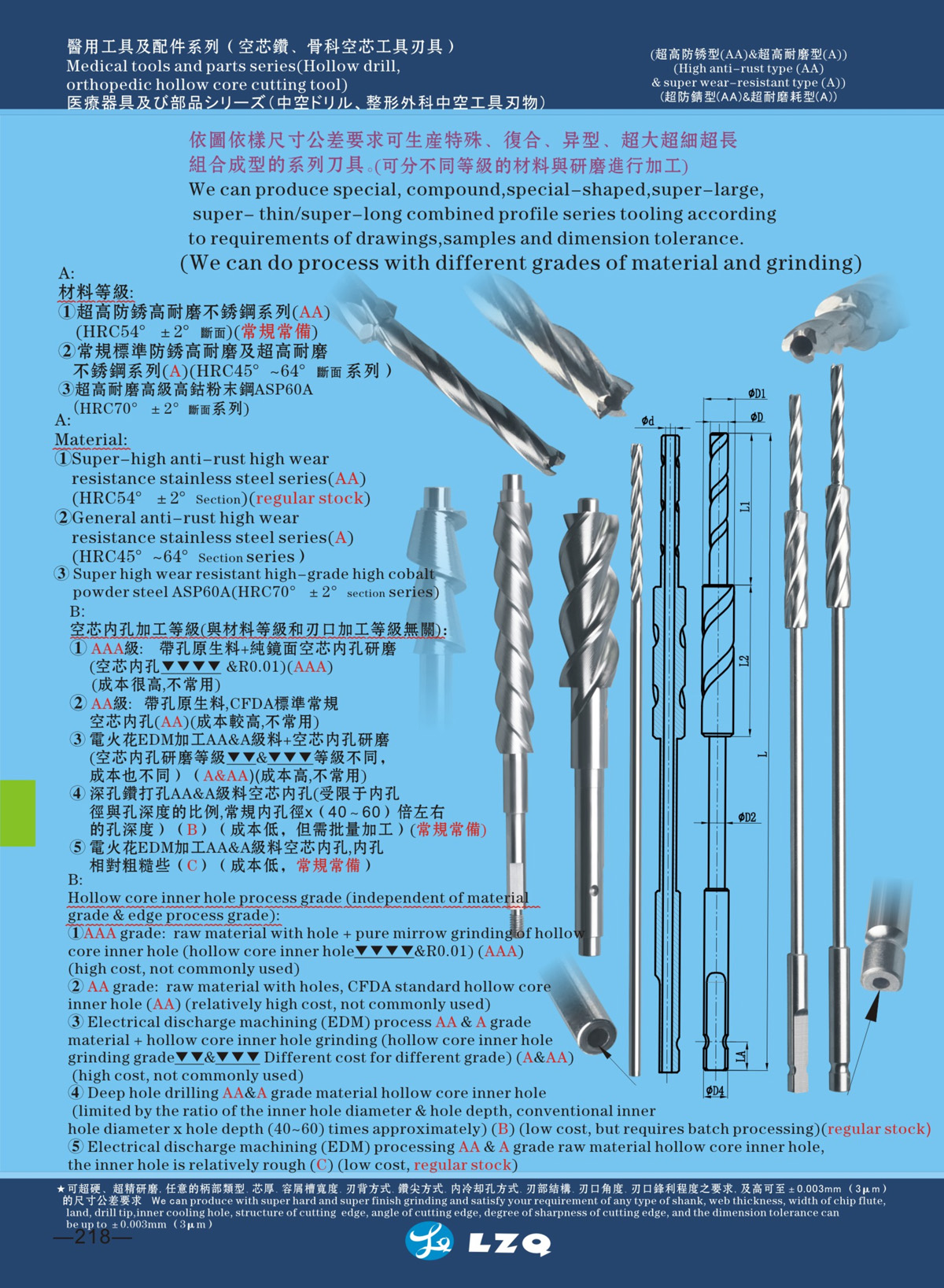

超高防锈高耐磨型(AA)&常规标准防锈超高耐磨型(A)

材料等级:

①超高防锈高耐磨不锈钢系列(AA)(HRC54°±2°断面) (常规常备)

②常规标准防锈高耐磨及超高耐磨系列(A)(常规常备) (HRC45°~64°断面系列)

③超高耐磨高级高钴粉末钢ASP60A(HRC70°±2°断面系列)

④高耐磨硬质合金系列 (AA)(HRA87°~94°系列)

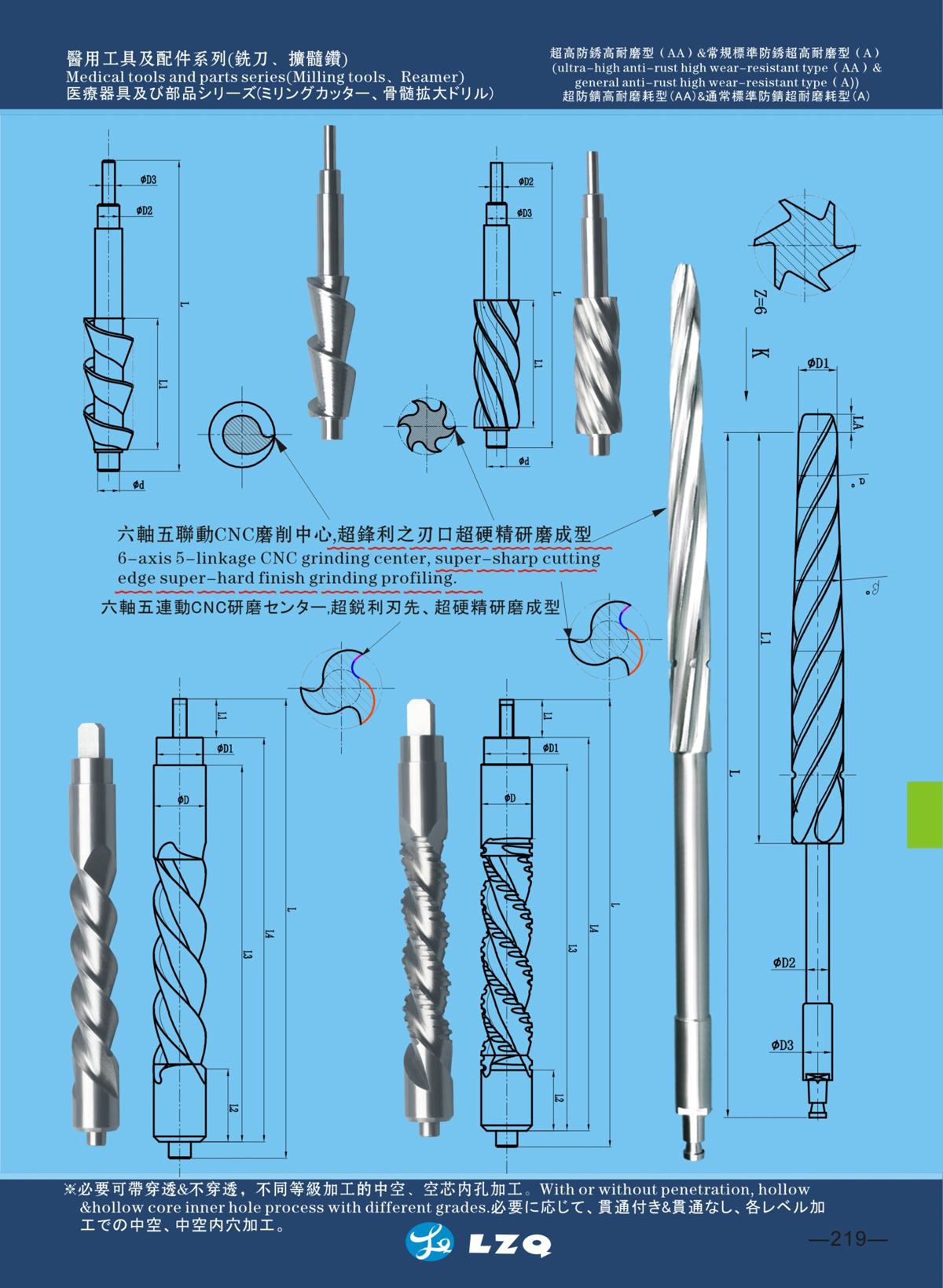

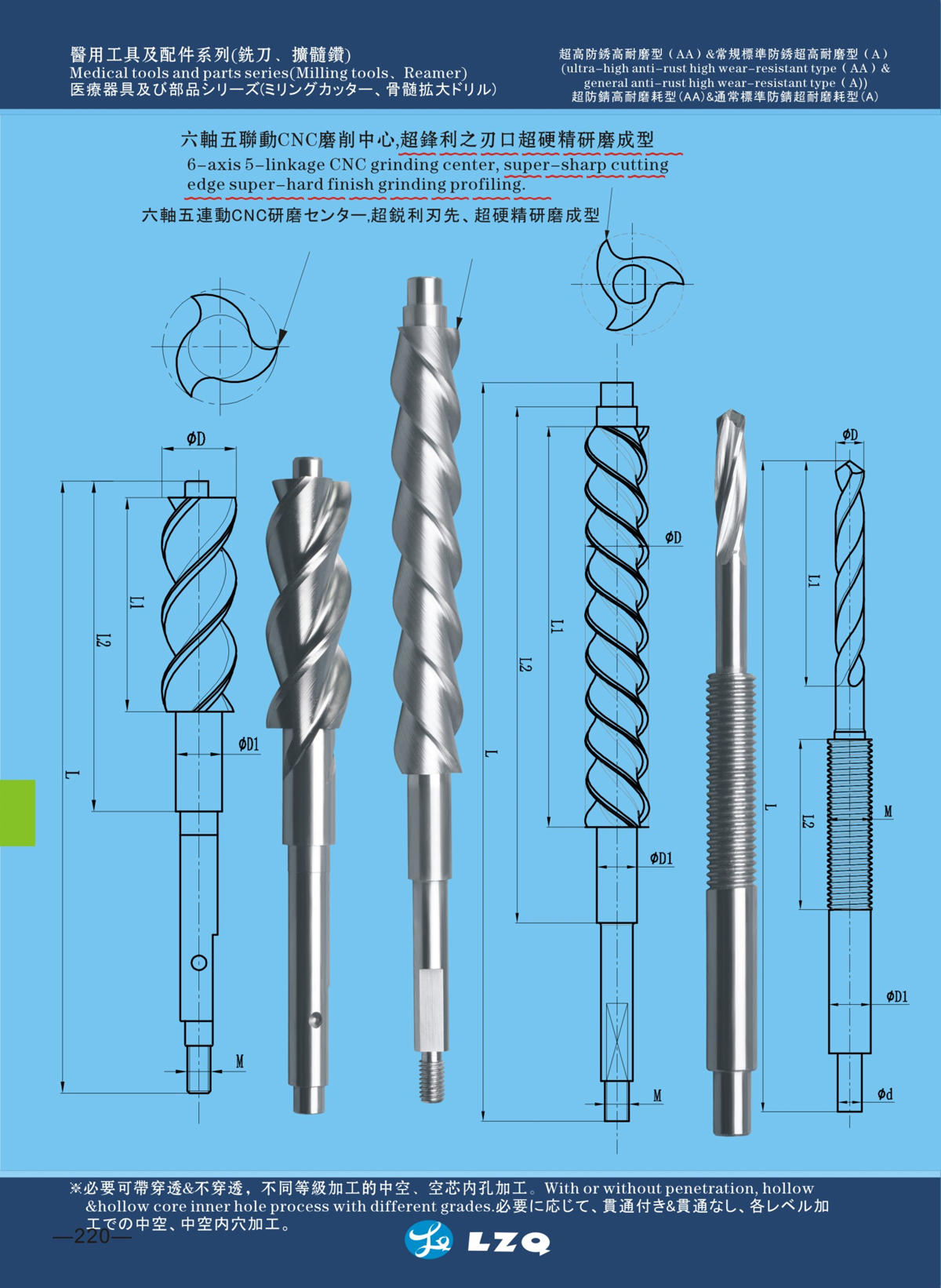

六轴五联动CNC磨削中心,超锋利之刃口超硬精研磨成型

刃口结构可以任意的排屑方式(如,上排屑、下排屑、左旋右切、右旋左切、左旋左切,右旋右切等等。高螺旋刃,低螺旋刃,带导柱不带导柱等等,结构形状之方式.

可超硬、超精研磨,任意的柄部类型、芯厚、容屑槽宽度、刃背方式、钻尖方式、内冷却孔方式、刃部结构、刃口角度、刃口锋利程度之要求,及高可至±0.003mm (3μm)的尺寸公差要求

与LZQ配合可以依贵司的设计能力和想法,实现对医疗工具用途的推广,从而建立起属于贵司自己的工具、治具、零配件产品体系。只要有CAD或3D图或使用效果最好的实样或依自己想法用3D打印机打印样件,或者用木头刻制属于自己想法的产品并标注尺寸公差,岭之崎即可采用指定的国际一流高品质素材和先进综合的生产体系,强力高速CNC磨削加工中心(3DX技术)成型超硬,超精研磨,具有完美的刃口品质和高可至±0.0005mm(±0.5um)的尺寸公差,依图依样现生产,具有极强的性价比。

Characteristics:

Application domain: for dental implantology

Material: Ultra high rust-proof and high wear-resistant stainless steel

LZQ is an OEM factory for all kinds of Maxillofacial surgery drill and bone drill, For example, orthopedic drill P228, Cranial bur P216, reamer / Marrow expansion drill P219, etc.. We can also produce a whole kit of tools for customers’ surgical cases.

We use the material of stainless steel.

We are capable to produce any Maxillofacial surgery drill according to drawings or samples provided by customer with a favorable cost-performance.

Products Description

(ultra-high anti-rust high wear-resistant type(AA)&general anti-rust high wear-resistant type(A))

Material grade:

①ultra-high anti-rust high wear-resistant stainless steel series (AA)(HRC54°±2°Section) (regular stock)

②general standard anti-rust,high wear-resistant and ultra-high wear-resistant series (A)(HRC45°~64°Section series)(regular stock)

③Super high wear resistant high-grade high cobalt powder steel ASP60A(HRC70°±2°section series)

④ultra-high wear-resistant hard alloy series(AA) (HRA87°~94°series)

6-axis 5-linkage CNC grinding center, super-sharp cutting edge super-hard finish grinding profiling.

edge structure can be applicable to any chip removing methods(such as, upper chip removal, lower chip removal, left handed right cutting, right handed left cutting, left handed left cutting, and right handed right cutting, etc. High helical edge, low helical edge, with guide pillar or without guide pillar, etc, different structures and shapes.

We can produce with super hard and super finish grinding and satisfy your requirement of any type of shank, web thickness, width of chip flute,land, drill tip,inner cooling hole, structure of cutting edge, angle of cutting edge, degree of sharpness of cutting edge, and the dimension tolerance can be up to ±0.003mm (3μm)

Cooperating with LZQ can help realize the promotion of the medical tools usages according to the design capabilities and ideas of your esteemed company, thus establishing your own tool kit, fixtures and spare parts product system. As long as you have CAD or 3D drawings, or samples with best using performance, or print the samples with a 3D printer, or use wood to engrave products with dimensional tolerances of your own ideas, LZQ can adopt a designated international first-class high-quality raw materials and advanced integrated production system, to do molding, superhard and ultra-fine grinding with the powerful high-speed CNC grinding machining center (3DX technology) according to drawings or samples, with perfect edge quality and dimensional tolerance up to ± 0.0005mm (± 0.5um), which is at a very good cost performance