软钻

软钻

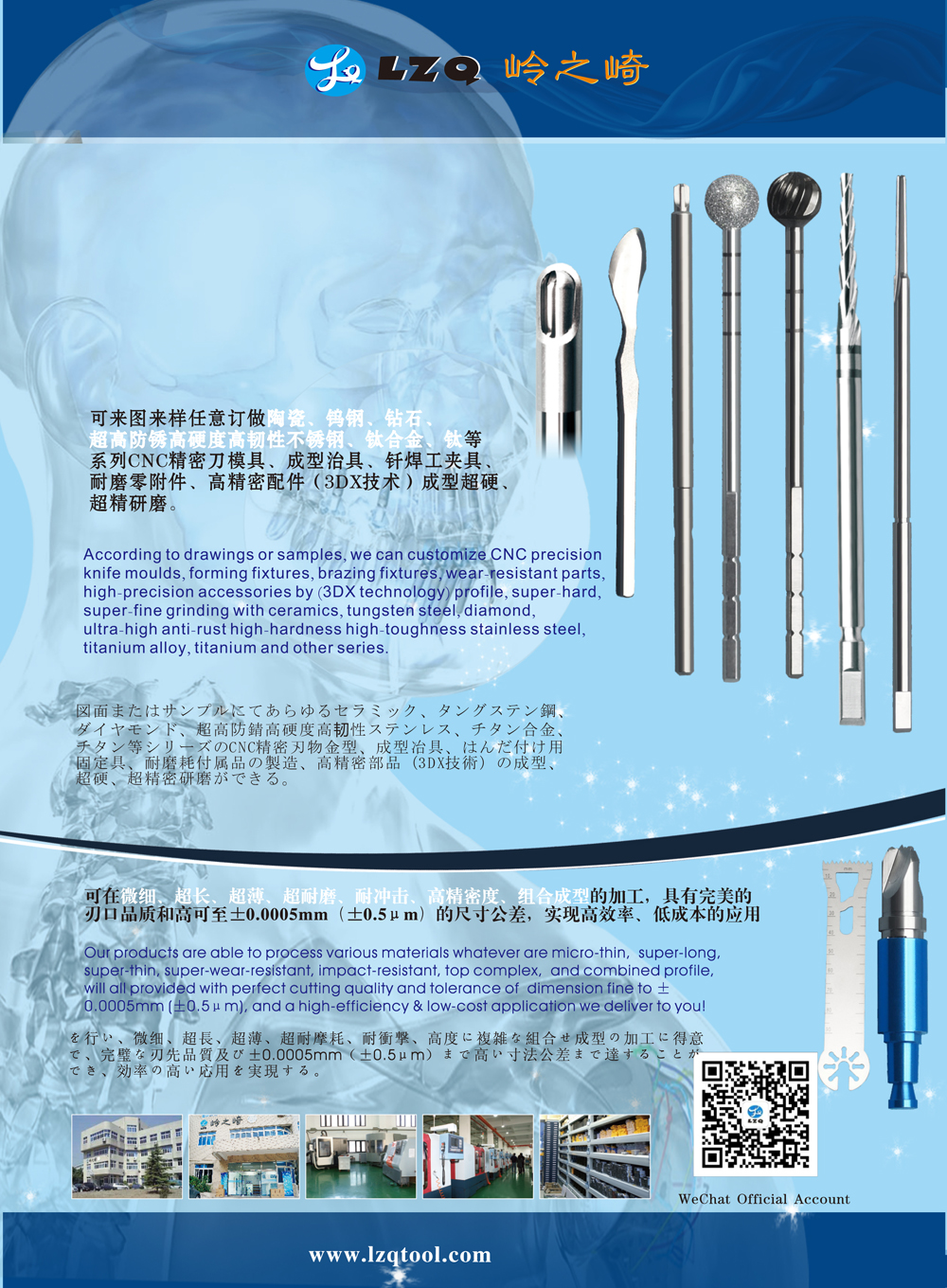

产品描述:

应用领域: 用于牙科种植

材 料: 超高防锈高耐磨不锈钢, 陶瓷

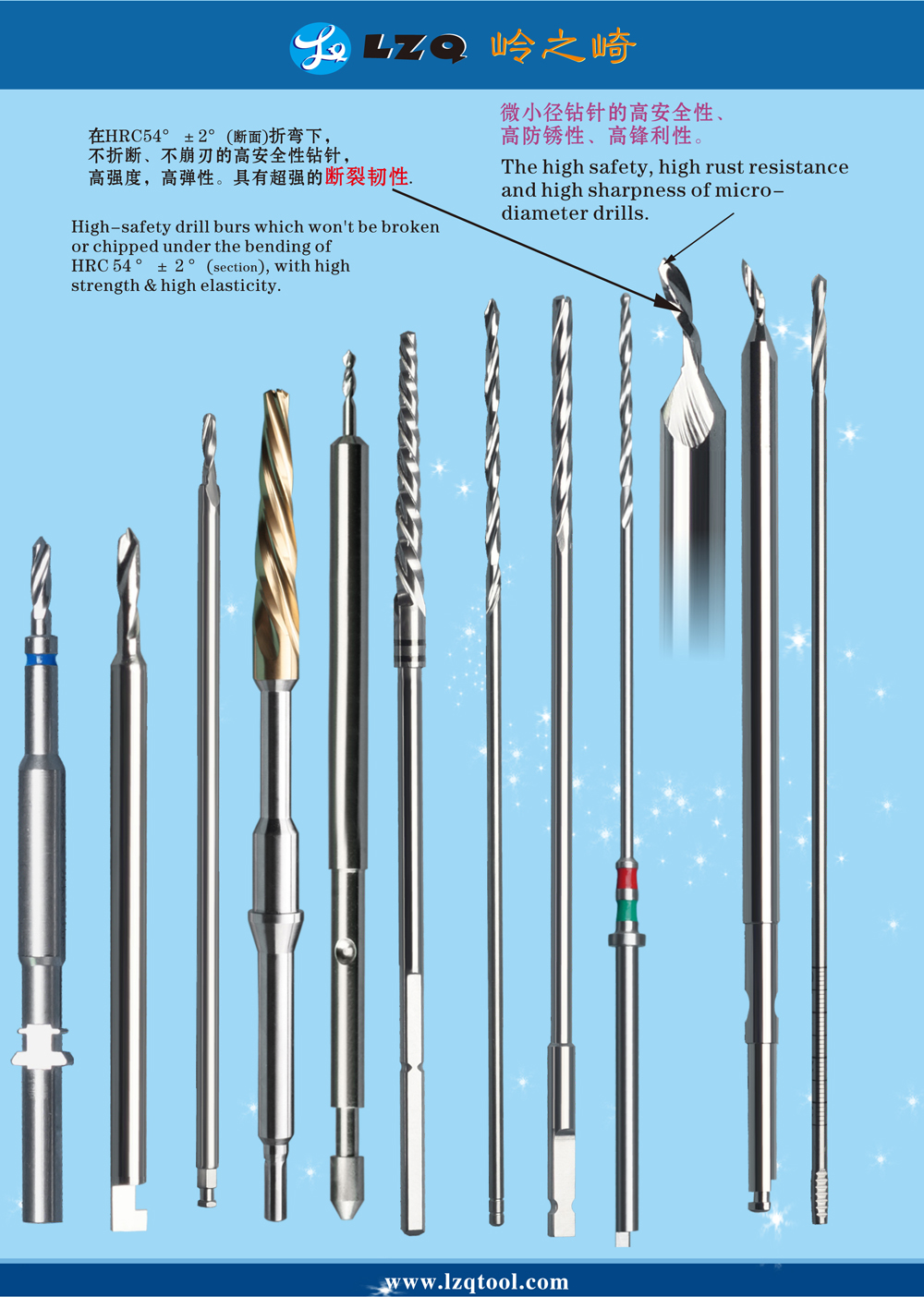

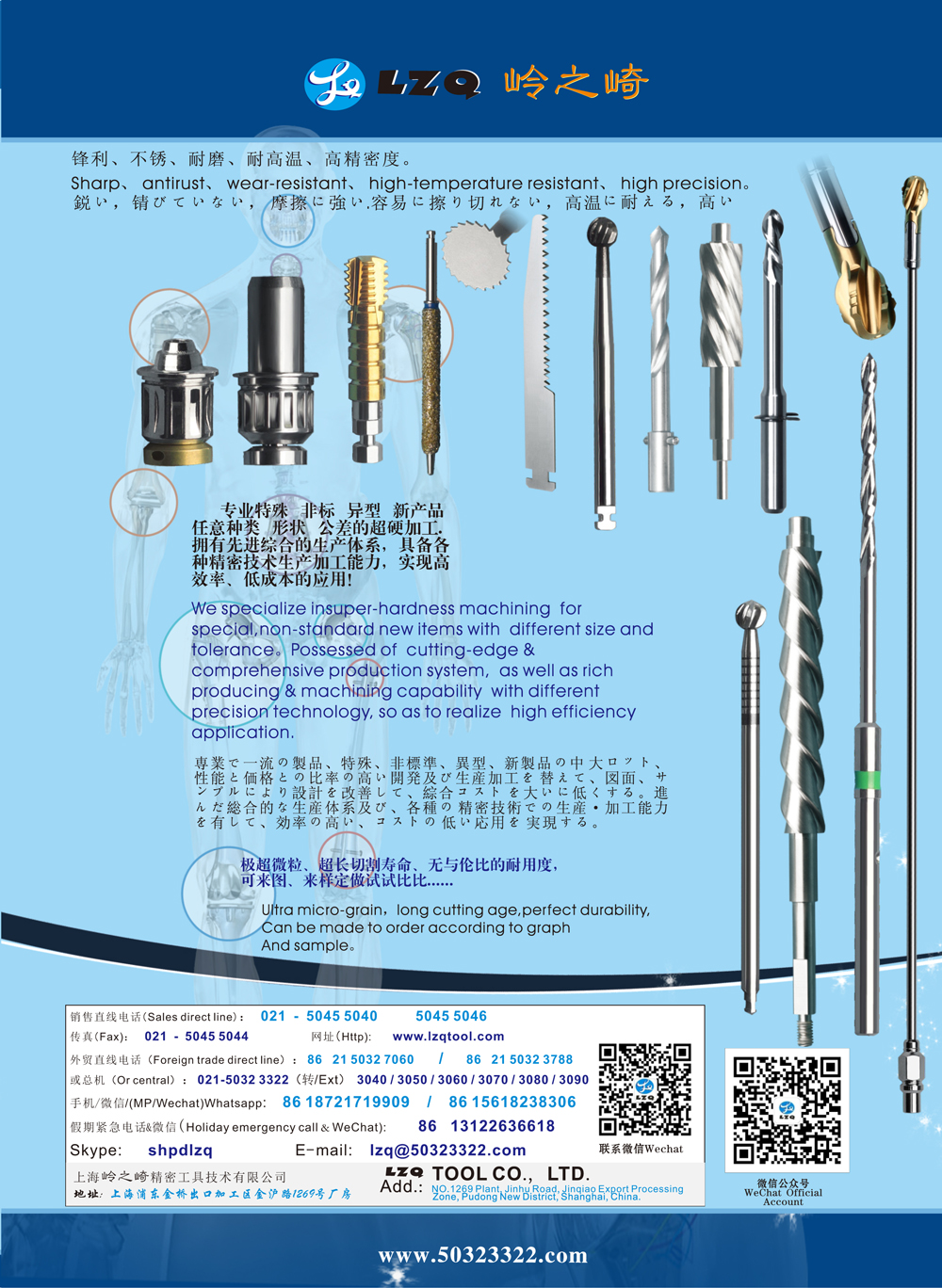

LZQ是一家生产各种颌面外科钻和骨钻的OEM代工工厂,例如,骨科钻头P228,颅骨铣刀P216,铣刀/扩髓钻P219,等等。我们也可以为客户生产成套手术工具。

我们使用不锈钢材料。

我们可以根据客户提供的任意图纸或者样品来生产任何颌面外科钻头,而且性价比很高。

刃口结构可以任意的排屑方式(如,上排屑、下排屑、左旋右切、右旋左切、左旋左切,右旋右切等等。高螺旋刃,低螺旋刃,带导柱不带导柱等等,结构形状之方式

岭之崎属高科技合资企业,本着速力中华、平和大同、传递健康、快乐与阳光……在外销型中、高端CNC精密刀模具、成型治具、钎焊工夹具、耐磨零附件、高精密配件、超高防锈高硬度不锈钢高精密零件上积累了二十多年的研究、生产经验。秉承先进综合的生产体系,拥有各种精密技术生产加工能力,引进国际一流的CNC设备、强力高速复合磨削加工中心及超强极超微粒高品质级素材,高精密(3DX技术)成型超硬、超精研磨,可在微细、超长、超薄、超耐磨、高耐冲击、高度复杂、组合成型的加工,具有完美的刃口品质和高可至±0.0005mm(±0.5um)的尺寸公差,实现高效率、低成本的应用!常年库存原材料、半成品、成品2000万~3000万RMB周转的在库品,依图依样现生产,快捷供货,具有极强的性价比……

与LZQ配合可以依贵司的设计能力和想法,实现对医疗工具用途的推广,从而建立起属于贵司自己的工具、治具、零配件产品体系。只要有CAD或3D图或使用效果最好的实样或依自己想法用3D打印机打印样件,或者用木头刻制属于自己想法的产品并标注尺寸公差,岭之崎即可采用指定的国际一流高品质素材和先进综合的生产体系,强力高速CNC磨削加工中心(3DX技术)成型超硬,超精研磨,具有完美的刃口品质和高可至±0.0005mm(±0.5um)的尺寸公差,依图依样现生产,具有极强的性价比。

Products Description:

Application domain: for implantology

Material: Ultra high rust-proof and high wear-resistant stainless steel,ceramic

LZQ is an OEM factory for all kinds of Maxillofacial surgery drill and bone drill, For example, orthopedic drill P228, Cranial bur P216, reamer / Marrow expansion drill P219, etc.. We can also produce a whole kit of tools for customers’ surgical cases.

6-axis CNC grinding center can be used to grind any shape, sharpness requirement, depth requirement of chip flutes, number of flutes, tooth profile, thread angle...

Create a flat surface on bone

Extracts desired bone with bone planer after initial drilling

Ultra-high rust-proof, high wear-resistant, high-impact & high-toughness stainless steel (AA) (HRC54°±2°section), The inner blade and outer blade sharpness retention time is super-long. And lifetime (wear resistance) is 60~100 times higher than that of the traditional AISI304L product,which can make the cutting edge stay super sharp for a long time.

LZQ possesses various precision technology production and processing capabilities. We have introduced world first-class CNC equipment, powerful high-speed compound grinding machining center and best ultra-super-fine particle high quality raw materials, high-precision (3DX technology) molding superhard & Superfine grinding. We can achieve perfect edge quality and size tolerance up to ± 0.0005mm (± 0.5μm) in fine, ultra-long, ultra-thin, ultra-abrasive, high-impact, highly complex and combined molding processing, which can realize high-efficiency and low-cost applications! We keep annual inventory of raw materials, semi-finished products and finished products amount to 20 million~30 million RMB turnover. We can produce according to drawings or samples with a fast delivery , also a very good cost performance...