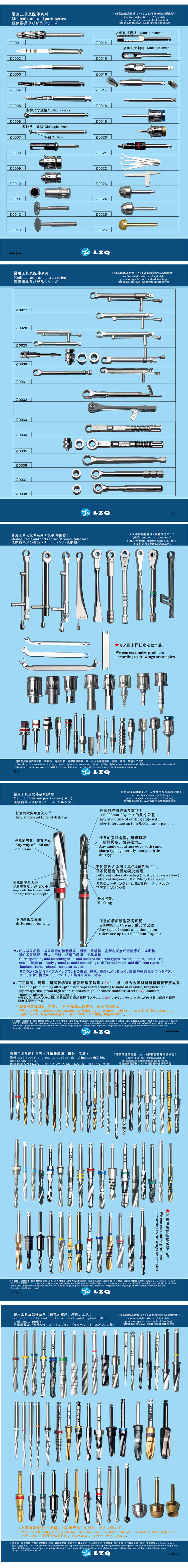

反角手机钻头延长器

反角手机钻头延长器

特性

应用领域: 种植

材 料: 超高防锈高硬度不锈钢, 钛, 钛合金, 高防锈不锈钢

产品描述

LZQ是一家生产各种牙科种植取骨器的OEM代工工厂,例如,延长器P44, 钻套P31,引导钻头P108,螺丝起子P79, , 侧切钻P150, 牙术 P175, 颅骨铣刀 P216, 骨锯 P250等等。

我们也可以为客户生产成套手术工具。

手术钢材料的延长杆-增加工具长度。配用钻头,螺丝起子,扳手,绞刀,等。最高等级的不锈钢和最先进的设计提高了工具的工作效果。表面哑光处理减少了反光,以达到最佳手术体验。

可依要求生产不同刃部材料类型(陶瓷类、钨钢类、超高防锈高级品不锈钢类(AA)、钛及钛合金类、常规标准防锈高耐磨不锈钢(A)......等系列)

A:加工精度等级:

1. 超高精密型(AAA)(精度高可至±0.0015mm(1.5um)的公差)(需批量)

2. 高精密型(AA)(精度高可至±0.005(5um)的公差)(常规加工)

3. 一般精密型加工(A)(精度高可至±0.010mm(10um)的公差(常规加工)

可生产极为复杂、精密的形状。工具、刀具可以激光分段、不同颜色的色圈、不同颜色的涂层、带内孔……要求,只要有要求及样品、CAD图,即可实现成型加工.

Drill extension contra angle handpiece

Characteristics

Application domain: for implantology

Material: Ultra high anti-rust & high-hardness stainless steel, titanium, titanium alloy, high anti-rust stainless steel

Products Description

LZQ is an OEM factory for all kinds of dental implant tools, such as Drill Extension P44, Drill Stopper P31,Guide Drill P108,Screwdriver P79, , Side Cutting Drill P150, Osteotome P175, Cranial Bur P216, Bone Saw P250, ect.

We can produce a whole kit of tools for customers’ surgical cases.

Extension available in surgical steel - To increase instruments' length. Use with drills, screwdriver, wrench and reamer, ect. Advanced grade of stainless steel and state-of-the-art design with improved working performance. A matte finish aids in reducing glare for an optimal surgical experience.

The cutting edge can be produced with different materials (ceramic, carbide, superhigh anti-rust and high wear resistant stainless steel (AA), Ti, Ti alloy, generally anti-rust and high wear resistant stainless steel (A) ... series)

A:Process finish grade:

1. Ultra High Precision type (AAA) (Tolerance accuracy up to ±0.0015mm (1.5um) need to be mass customized)

2 . High Precision (AA) (Tolerance accuracy up to ±0.005 (5um)) (Conventional Machining)

3. General precision machining (A) (Tolerance accuracy

up to ±0.010 mm (10 um))( Conventional Machining)