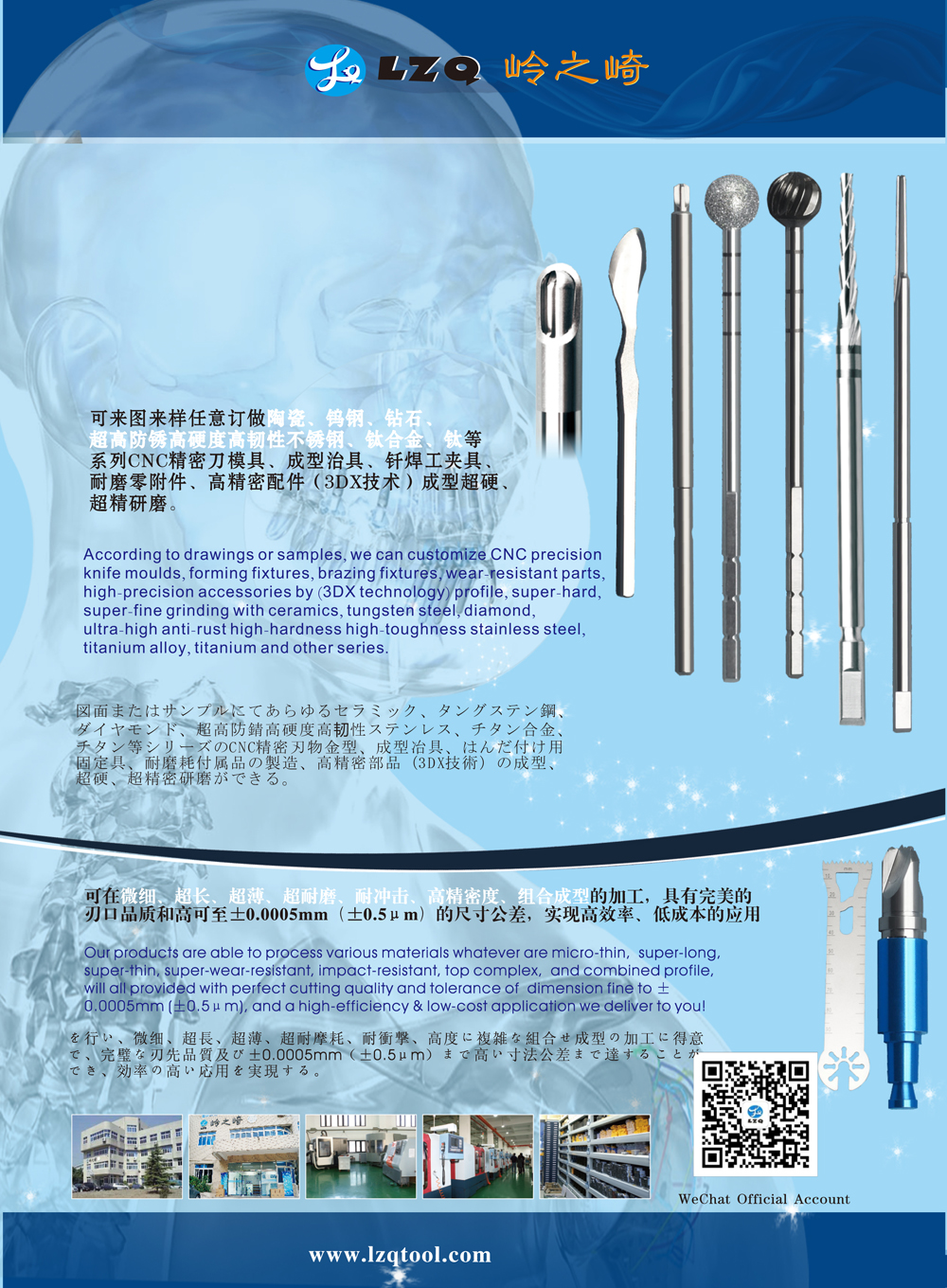

空芯钻

应用领域: 骨科手术, 颌面外科, 神经外科

材 料: 超高防锈高硬度不锈钢, 超高防锈高耐磨不锈钢,

金刚石,钨钢

空芯钻

特性

应用领域: 骨科手术, 颌面外科, 神经外科

材 料: 超高防锈高硬度不锈钢, 超高防锈高耐磨不锈钢,

金刚石,钨钢

产品描述

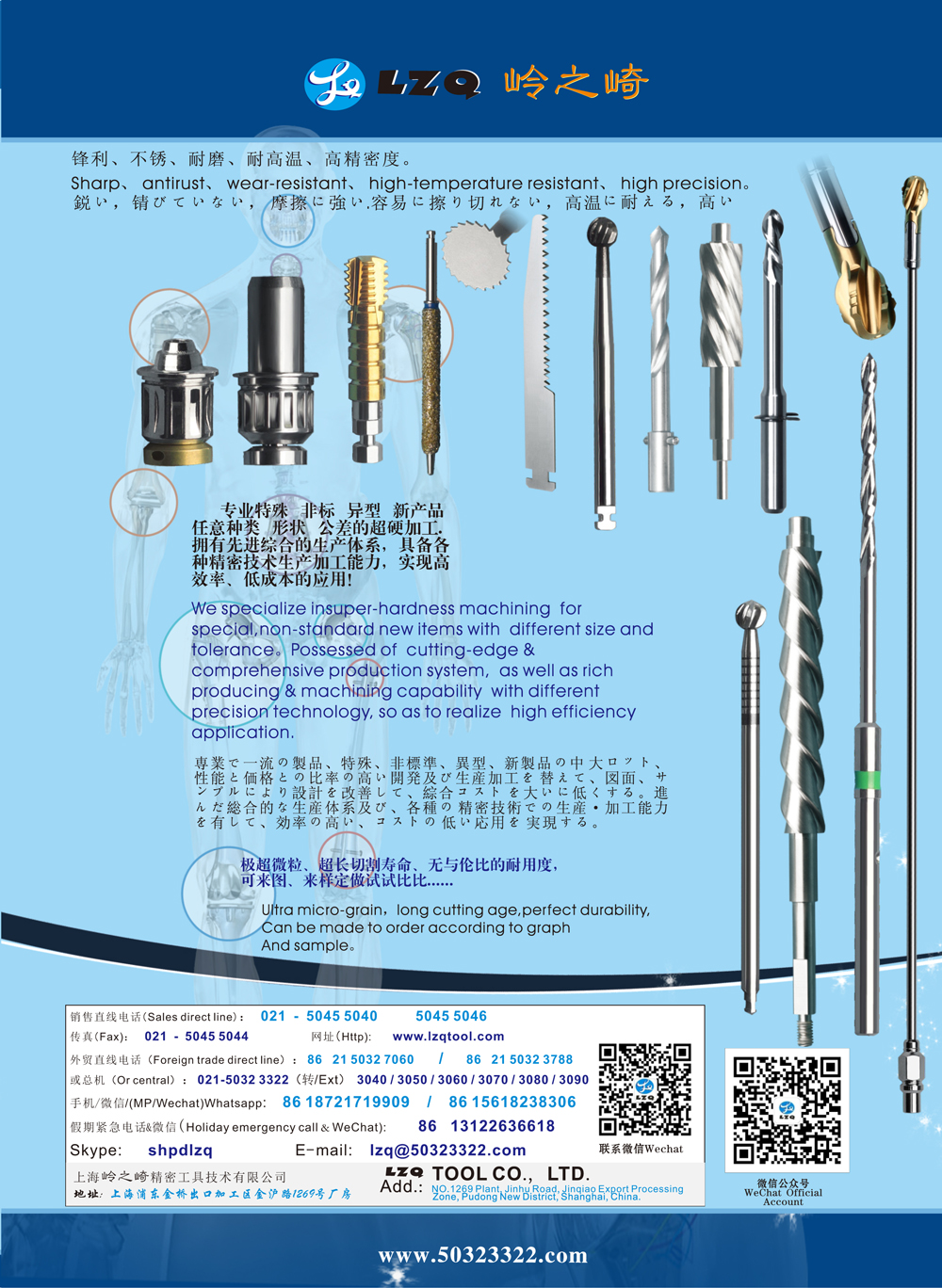

LZQ是一家生产各种医用锉的OEM代工工厂,例如,切割锉/骨锉 P190, 钻套P31, 钻头096, 基台/转移杆P25, 骨锯 P250, 压板P47,内窥镜/关节镜刨刀 P259, 骨科钻针 P227,等等。我们也可以为客户生产成套手术工具。

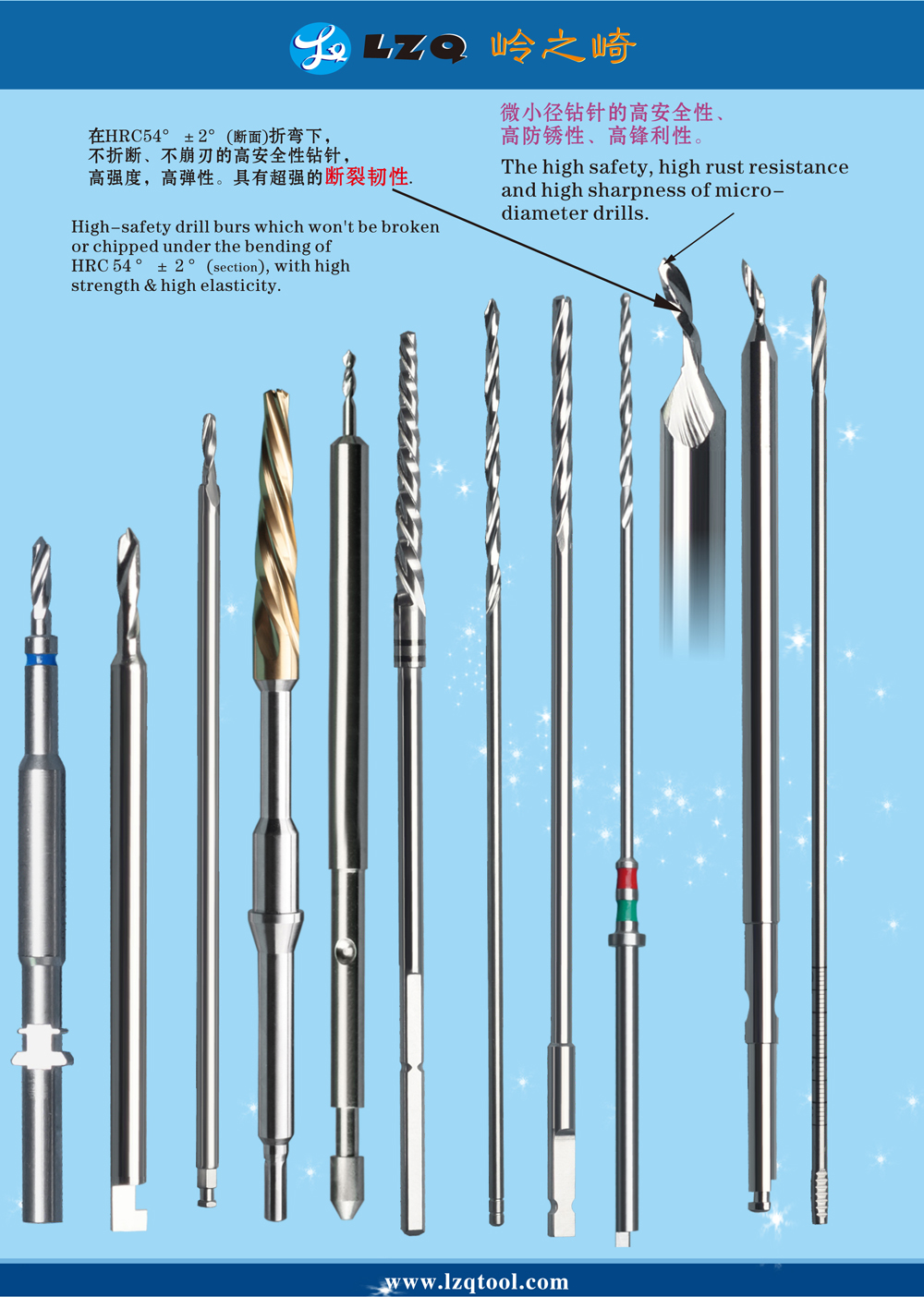

(超高防锈型(AA)&超高耐磨型(A))

A:

材料等级:

- 高防锈高耐磨不锈钢系列(AA)(HRC54°±2°断面)(常规常备)

②常规标准防锈高耐磨及超高耐磨不锈钢系列(A)(HRC45°~64°断面系列)

B:

空芯内孔加工等级(与材料等级和刃口加工等级无关):

- AA级: 带孔原生料+纯镜面空芯内孔研磨

(空芯内孔▼▼▼▼ &R0.01)(AAA) (成本很高,不常用)

② AA级: 带孔原生料,CFDA标准常规空芯内孔(AA)(成本较高,不常用)

- 电火花EDM加工AA&A级料+空芯内孔研磨

(空芯内孔研磨等级▼▼&▼▼▼等级不同,成本也不同)

(A&AA)(成本高,不常用)

- 深孔钻打孔AA&A级料空芯内孔

(受限于内孔径与孔深度的比例,常规内孔径x(30~40)倍左右的孔深度)(B)(成本低,但需批量加工)

- 电火花EDM加工AA&A级料空芯内孔,内孔相对粗糙些(C)

(成本低,常规常备)

全精研磨▼▼▼~▼▼▼▼

材质:不锈钢(HRC35°~64°系列)纯钛、钛合金;高速钢;

钴高速钢;合金钢;钨钢;硬质合金;陶瓷。

Core drill

Characteristics:

Application domain: orthopedic surgery, maxillofacial surgery, neurosurgery

Material: Ultra-high anti-rust and high-hardness stainless steel ,Ultra high rust-proof and high wear-resistant stainless steel, diamond, carbide

Products Description

LZQ is an OEM factory for all kinds of medical bur, such as Cutting Bur/Bone File P190, Drill Stopper P31, Drill Bit 096, Abutment/Transfer P25, Bone Saw P250 , Drill Key P47,Endoscopic/Arthroscopic Shaver blade P259, Bone Drill Point P227,etc. We can also produce a whole kit of tools for customers’ surgical cases.

(High anti-rust type (AA) & super wear-resistant type (A))

A:

material:

①Super-high anti-rust high wear resistance stainless steel series(AA) (HRC54°±2°Section)(regularly stock)

②General anti-rust high wear resistance stainless steel series(A)

(HRC45°~64°Section series)

B:

Hollow core inner hole process grade (independent of material grade & edge process grade):

①AA grade: raw material with hole + pure mirrow grinding of hollow core inner hole (hollow core inner hole ▼▼▼▼ &R0.01) (AAA) (high cost, not commonly used)

② AA grade: raw material with holes, CFDA standard hollow core inner hole (AA) (relatively high cost, not commonly used)

③ Electrical discharge machining (EDM) process AA & A grade material + hollow core inner hole grinding (hollow core inner hole grinding grade ▼▼& ▼▼▼▼Different cost for different grade) (A&AA) (high cost, not commonly used)

④ Deep hole drilling AA&A grade material hollow core inner hole (limited by the ratio of the inner hole diameter & hole depth, conventional inner hole diameter x hole depth (30~40) times approximately) (B) (low cost, but requires batch processing)

⑤ Electrical discharge machining (EDM) processing AA & A grade raw material hollow core inner hole, the inner hole is relatively rough (C) (low cost, regular stock)

Fine finish grinding, ▼▼▼~▼▼▼▼

Material: stainless steel( HRC35°-64° series),pure titanium,

titanium alloy;HSS;Cobalt HSS; alloy steel ;carbide; hard alloy; ceramic。